Michigan is a state in the Great Lakes region of the upper Midwest of the United States. Its largest city - Metro Detroit, is one of the most populous and largest metropolitan economies in the U.S. Although Michigan’s economic development has diversified, it is widely recognized as the center of the U.S. auto industry in the early 20th century and developed into a major economic force in the state. It is home to the nation’s three largest auto companies - GM, Ford, and Chrysler (all headquartered in Metro Detroit). Once developed for logging and mining, the sparsely populated Upper Peninsula is now greatly vital to tourism because of its abundance of natural resources. The Lower Peninsula is the center of high-tech industries, forestry, agriculture, and manufacturing.

As of 2002, Michigan had the fourth-highest high-tech employment rate in the United States, with 568,000 high-tech workers, including 70,000 in the auto industry. The state is a great source of engineering jobs. The domestic auto industry directly and indirectly accounts for one in ten jobs in the United States.

Runsom always provides the best support on micro machining of prototypes and large quantity productions for engineers, product developers, and designers in Michigan. We are looking forward to collaborating with you.

5-Axis & Swiss Machining for Detroit Businesses

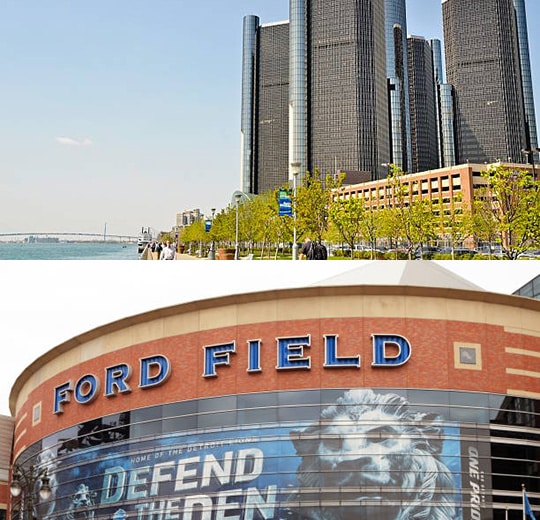

Detroit has enjoyed a high reputation for its automotive powerhouse in the world. However, “Motor City” isn’t just about cars: Detroit is one of the increasingly growing cities in education, advanced manufacturing, and technology. Home to the nation’s three largest auto companies - GM, Ford, and Chrysler, Detroit is attracting more and more high-tech industries requiring precision machining.

Our cooperating machine shops in Michigan have a team of engineers and technicians with decades of experience and employ comprehensive machining processes including 5-axis milling, CNC Turning/lathe, and Wire EDM to reach flawless results and desired effects that clients want, all to make your products fantastic. Runsom consistently moves ahead to grow and develop with Detroit together with our premier CNC machining services supporting businesses across the city.

No matter what products you need - impellers, miniature gears, sonic nozzles, or some challenging tasks that other machine shops have no capability to complete, Runsom is here to fulfill your requirements exactly.

Precision CNC Machining Serving Detroit Automotive, Michigan

Detroit’s auto industry has laid the foundation for growth in other major industries throughout Michigan. With the growing demand for ultra-precision and high-quality machining, Runsom will move forwards to provide top support to meet those needs. The state-of-the-art facility - dust and temperature controlled for high-end manufacturing processes, allows our machinists to deliver top-quality products crafted with ultimate precision and high quality.

Runsom works with well-known Swiss and German corporations to produce identical parts at very high volumes at a very low cost per part by utilizing the latest CNC machining technologies below:

Custom Precision Components Made for Industries in Michigan

Count on Runsom Precision for your custom CNC machining services in Michigan. Vast industries across the United States are beneficial from our micromachining services, including medical, food manufacturing, automotive, and aircraft industries. With an experience of over ten years of making sophisticated components needing exceptional accuracy, the tightest tolerances, and the highest precision, we have the capability of accepting challenges other machine shops in Michigan cannot tackle, exactly catering to customers’ needs and each crucial specification.

Your Michigan CNC Machining Service Supplier - Runsom Precision

CNC machining confers abundance of benefits to applications demanding parts with ultimate precision and tolerance. You can rest assured that it’s a wise and right choice to place your order and get it done at Runsom. What makes us outperform our rivals is our extreme attention to detail, dedication to precision and high level of expertise garnered in our employees.

Send an RFQ – your drawing or 3D CAD model is available for the quotation.