Stainless Steel CNC Machining Service

Precision stainless steel CNC machining services

Get custom stainless steel parts in as fast as days

Quick quote available within 24h

Stainless Steel CNC Machining Services - Custom Stainless Steel Parts

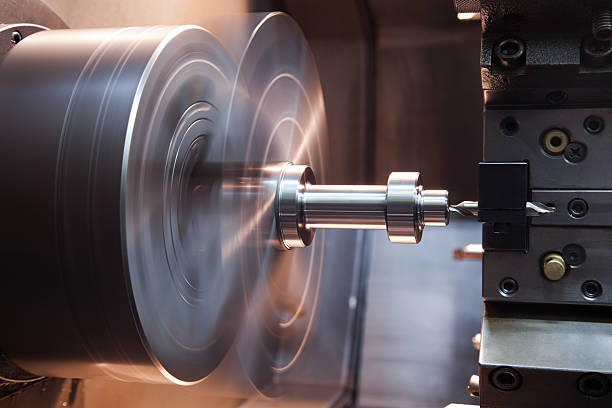

Runsom Precision, a premier manufacturer of stainless steel parts, utilizes advanced 3-, 4-, and 5-axis CNC machining technology to create stainless steel parts with wonderful mechanical properties, high precision, and repeatability. With our extensive experience and top-notch equipment, high-quality stainless steel parts can be produced for complex projects with great precision and high tolerance, exactly conforming to stated specifications while saving time and cost.

Focused on custom CNC machining in stainless steel for decades, Runsom Precision has become one of the most reliable and affordable suppliers in the industry. We utilize advanced multi-axis steel CNC machines to process stainless steel parts with the best quality and accuracy. Our technical team has a professional understanding of every detail of CNC machining stainless steel, especially in some manufacturing processes, such as CNC steel milling, turning, drilling, and steel prototyping. Equipped with advanced facilities paired with our highly skilled machinists of rich experience, our machining center can create CNC machined stainless steel components with incredibly tight tolerances.

Benefits of CNC Machining in Stainless Steel

CNC machined stainless steel parts show numerous advantages in a wide variety of applications.

For parts needed to be machined from thinner metal, stainless steel would be a suitable choice because of its excellent strength-to-weight ratio. More importantly, the strength of stainless steel can be further strengthened via heat curing and cold hardening processes, because stainless steel has great tolerance to harsh environments like extreme temperatures. Martensitic stainless steels hold the highest strengths over other metallurgical structures of stainless steel.

Stainless steel can be cut, formed, machined, and welded as easily as conventional steel due to its great flexibility. To further improve its formability, sulfur is normally added to stainless steel. The austenitic stainless steel is well-known for its most formable and versatile variation.

Stainless steel can be used in many applications given its high corrosion resistance. Different grades of alloyed steel can suffer different levels of corrosion resistance. The grade higher, the capability of resistance to corrosion greater. The austenitic stainless steel is capable to bear exposure to corrosive environments like acids, chloride, and alkaline solutions.

Using stainless steel in CNC machining can increase the lifespan of parts and cut back on maintenance costs. Stainless steel can also resist rusting and corrosion, so it outperforms other metals with these combined properties at a cost-efficient price.

A delicate appearance is always on-demand in the manufacturing industry. Stainless steel can satisfy modern decoration with an attractive appearance since it’s available in a wide kind of surface finishes.

Stainless Steel Grades We Work With

If you are preparing to choose stainless steel as the material of your part in CNC machining, you may rest assured that you are choosing a kind of material with plenty of advantageous properties. Due to the versatility of CNC machining, it may be a challenge for engineers to target the exact one suitable for specific projects in the list of materials.

Runsom's team of expert designers would like to face challenges, owing to their decades of engineering experience. The material selection will definitely turn out to be perfect and much easier for your expected results. The following are briefs about the main grades of stainless steel we have experience with:

│Stainless steel 303

This is an austenitic steel variety that can be most easily machined. This stainless steel has great toughness but its resistance to corrosion may be lowered when adding sulfur to it. It’s suitable for high volume production by virtue of its good machinability.

│Stainless steel 304

This type of stainless steel contains 8% nickel, 18% chromium, and a maximum carbon concentration of 0.07%. Its superior properties such as good formability and corrosion resistance can be shown after CNC machining. It is applied to decorate any kitchen, home design, and theme.

│Stainless steel 416

This is a steel grade with the highest machinability. However, it achieves its increased machinability by sacrificing the corrosion resistance, so it is generally easy to be eroded compared to other stainless steel counterparts.

│Stainless steel 17-4PH

This is a precipitation-hardened (PH) steel grade with excellent corrosion resistance and oxidation. It can be hardened up to 44 HRC. The mechanical properties of this steel can be easily enhanced by heat treatment. Applications include gas turbines and chemical processing parts.

│Stainless steel 15-5

This is a precipitation-hardened (PH) metal. Compared to other martensitic grades, it has better transverse properties, strength, and toughness. The low-temperature heat treatment can be used to improve its mechanical properties.

If you still have no idea about which type of stainless steel material is best suited for your CNC machining needs, Runsom just has your answer. We are ready for every challenge and strive for being the best in this industry. Just upload your design file and receive an instant quote, as well as DfM feedback.

Finishes and Post-Processing Options

We offer a wide variety of surface finishes available for CNC machined stainless steel, including:

As machined

The original state is left after the stainless steel part is machined. 125 Ra or better can be achievable at Runsom. The surface roughness can be further refined via finishing passes. This is the most common surface finishing method for stainless steel.

The original state is left after the stainless steel part is machined. 125 Ra or better can be achievable at Runsom. The surface roughness can be further refined via finishing passes. This is the most common surface finishing method for stainless steel.

Polishing

Polishing has been pivotal in increasing the aesthetics of metalwork. Apart from this, it also adds the ability that metal t withstands harsh circumstances. Meanwhile, polishing remains instrumental in figuring out the shape of the mold and the final product manufactured using the polished mold.

Polishing has been pivotal in increasing the aesthetics of metalwork. Apart from this, it also adds the ability that metal t withstands harsh circumstances. Meanwhile, polishing remains instrumental in figuring out the shape of the mold and the final product manufactured using the polished mold.

Bead blasting

It is commonly used for cosmetic purposes. A uniform and smooth matte finish is formed by blasting the surface lightly.

It is commonly used for cosmetic purposes. A uniform and smooth matte finish is formed by blasting the surface lightly.

Passivation

In the case of stainless steel, we use nitric acid or citric acid in the passivation process to eliminate the free iron present on the surface. A defensive layer of oxide that is less chemically reactive with the air around it to prevent corrosion is formed by this chemical treatment. In turn, when stainless steel gets passivated, it will resist rusting and corrosion. Learn more about Passivation of Stainless Steel Parts.

In the case of stainless steel, we use nitric acid or citric acid in the passivation process to eliminate the free iron present on the surface. A defensive layer of oxide that is less chemically reactive with the air around it to prevent corrosion is formed by this chemical treatment. In turn, when stainless steel gets passivated, it will resist rusting and corrosion. Learn more about Passivation of Stainless Steel Parts.

Our Stainless Steel CNC Machining Services

Full series of materials

The main types of stainless steel we offer: stainless steel 303, stainless steel 304, stainless steel 316, stainless steel 416, stainless steel 17-4PH, and stainless steel 15-5.

Surface finishing

There is a wide variety of surface finishes available for CNC machined stainless steel: as machined, powder coating, bead blasting, sand blasting, anodizing, and polishing.

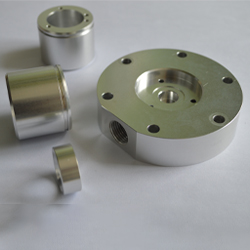

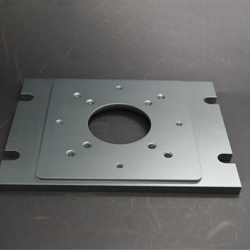

Various types of parts

Hospital and lab instruments, cables, handles, marine parts, engine parts, weld ferrules, automotive parts, electronic parts, medical devices, etc.

One-stop machining

CNC stainless steel milling, CNC stainless steel turning, CNC stainless steel drilling, and CNC stainless steel threading.

Why Choose Us for Your CNC Stainless Steel Machining

15 Years of Experience

You may rest assured that we have an experienced engineering team, advanced production, inspection equipment, and mature management systems.

Save Your Cost

We have optimized the manufacturing process combinations that will greatly save the production cost with the production capabilities of stainless steel parts expended.

Quality Reliability

Certificated by ISO9001:2015, we have strict requirements for quality. To meet high quality, we have a sound quality control system and well-equipped measuring devices.

CNC Machining of Stainless Steel FAQs

In stainless steel CNC machining, a stainless steel block is processed to form a final desired shape, size, or surface finish. The high precision and exact geometry will be realized by a computer numerically controlled (CNC) milling tool.

In modern society, stainless steel part is popular among many industries and perfect for a variety of applications from tiny medical tools to huge skyscrapers. With its desirable physical properties, it has become an industrial alloy suitable for many CNC machining projects.

The cost of CNC machining stainless steel is determined by several aspects, including the size, geometry of the part as well as the needed type of stainless steel. All the factors will have a direct impact on the choice of the type of machine, the manufacturing time, and the production cost.

We can make correct pricing quickly from the 3D CAD file, based on our experience of dealing with thousands of valuable data from previous CNC machining orders. What you need to do is just upload your CAD file online. The free quote will be sent to you within 24h.

We have stocked nearly all series of stainless steel for your CNC machining projects. The main types of stainless steel we offer: stainless steel 303, stainless steel 304, stainless steel 316, stainless steel 416, stainless steel 17-4PH, and stainless steel 15-5.

Based on its crystalline structure, stainless steel can be classified into five primary categories:

- Austenitic Stainless Steels

- Duplex Stainless Steels

- Ferritic Stainless Steels

- Martensitic Stainless Steels

- Precipitation Hardened Stainless Steels

- Great tensile strength

- Incredible wear and corrosion resistance

- Excellent formability and weldability

- Hygienic with excellent cleanability

- Good performance at extreme temperatures

Ready to Get a Quote?

Turn your CNC parts into reality today