Rapid Prototyping Services

Online rapid prototyping services

Fast transition from design to production

Various material and finish combination options

Runsom Precision offers exceptional rapid prototyping services with incredible quality, on-time delivery, and competitive price to customers around the world. Our engineering team has utilized the latest prototyping technologies with extensive knowledge and experience. With our prototyping centers, we are ideal to provide comprehensive services to satisfy global customers' requirements, timescales, and special needs. Runsom Precision can take your concepts or designs to reality production in just days with our proven prototyping technologies and processes.

What Is Rapid Prototyping?

Rapid prototyping is a specialized manufacturing technique for high-quality physical models with 3D design concepts. Prototypes are very useful in design development and improvement processes as a significant basis for production or engineering testing. Prototyping is quick and economical for both personal companies and research institutions in that they never need to invest in hard tooling equipment.

Speed and affordability are the key essences for rapid prototyping. As its name shows, it emphasizes a fast turnaround. So it's expected to produce a physical part in a short time to validate the design, and then capture business chances.

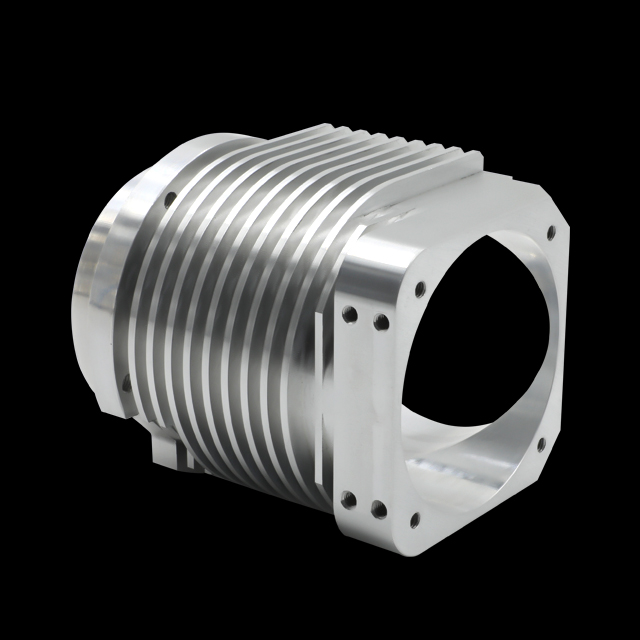

This is a conventional prototyping method as well as a widespread way for metal prototyping. Runsom Precision has rich experience for 10 years in various CNC prototype manufacturing in many industries, such as automotive, electronics, energy, medical, etc.

CNC machining prototypes will provide the best precision and surface finishes. In addition, the selection of materials is unlimited as well. However, CNC machining will take a long time to prepare and set up, so we always apply this technology for high precision and metal material prototypes.

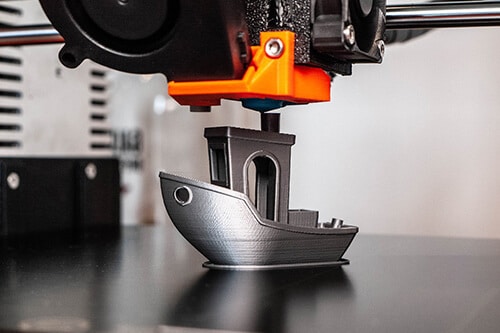

Different 3D printing technologies are suitable for different rapid prototyping stages as a pioneer in this industry.

For instance, SLA prototyping requires liquid plastic material and may provide the best finish surface; SLS prototyping is similar to SLA, but the material form needs to be powerful. FDM prototyping is the cheapest and fastest method in 3D printing technology. This additive prototyping process will finish a complete prototype part within one day. However, materials used in the 3D printing process are too expensive for the manufacturing process.

Sheet metal fabrication is a subtractive manufacturing process involving forming parts from thin metal sheets by cutting, bending, folding, stamping, and assembling. Sheet metal parts are usually highly precise and durable, making them particularly preferred by engineers to use for end-use applications such as enclosures, brackets, and chassis.

Sheet metal fabrication can provide competitive prices for small volume production of prototypes, as well as cost savings for large volume production. Runsom Precision offers high precision cutting, bending, punching, and welding of sheet metal, as well as assembly services.

Vacuum casting, also called urethane casting, offers a cost-effective choice for producing small quantities of plastic parts, closely mimicking the properties of final molded items or finished products.

Typically, molds are created from silicone rubber, using CNC machining or SLA parts as the master pattern. These molds excel in replicating intricate details and textures, ensuring uniform quality across different parts.

This method allows for the production of parts with similar mechanical characteristics, wall thickness, colors, and surface textures as those found in mass-produced items.

What is the Difference between Different Prototyping Processes?

The choice of manufacturing process for rapid prototyping is ultimately determined by the scale of production and appropriate materials for a particular project.

Advantages of Rapid Prototyping

The main advantages of rapid prototyping are as follows:

Offer multiple options

Capable of producing a wide variety of prototypes with different colors and surface textures.

Save cost & time

The small-volume prototyping run helps to minimize the costly design flaws. And it can be time-saving by eliminating the need for setup and tooling.

Refine the product with iterative rapid prototyping

Improved evaluation and functional testing of the product will be achieved by reiterating designs. Your product can be optimized before taking it to the market.

Transform a concept into a physical model

Your designs or ideas will be visualized by design for manufacturability (DFM) in a fast and cost-effective manner so that you can easily grasp the design of a product and business opportunities in the physical world.

Why Choose Runsom Precision for Rapid Prototyping?

Superior technology and equipment

Our specialized equipment and machinists allow us to outperform our competitors in the industry. We are constantly innovating and developing advanced methods to improve all aspects of production.

Wide range of materials

Runsom Precision is an ideal option for your prototyping project to be completed in one place because we stock nearly all types of materials.

Unmatched capabilities

We offer rapid prototyping services from single prototype to high volume production. We never have minimum order quantities or dollar value requirements and will do everything possible to meet your needs.

Guaranteed quality and rapid lead time

We treat every order with precise specifications and strict delivery times. Lead times and product quality are critical to rapid prototyping. At Runsom Precision, we offer you the best of both worlds, ensuring that you get a quality product and timely receipt of your order.

Instant response to every request

We are committed to responding quickly to every request from our customers. You can get an instant quote online without having to double-check in your mailbox that the quote has been sent back.

Competitive price

Our efficient rapid prototyping system allows us to provide cost-effective solutions based on our clients' budgets and counter offers.