At Runsom, you can experience comprehensive service for aluminum CNC machining. There are multiple types of aluminum and geometries for your options. Excellent aluminum properties offer high durability, corrosion resistance, heat tolerance, lightweight, and low cost for applications in a wide range of industries. At Runsom, nearly all series of CNC machine shops are able to manufacture aluminum parts on your demand, no matter for simple, as-machined, or complex geometries with tight tolerances. Also, we provide post-machining process services to enhance the physical, mechanical, and aesthetic features of the part.

CNC Aluminum Prototyping

Selecting the exact material is an important access to open up a new application applying to wide industries. Being an effective way to address complex design verification and pre-production testing before mass manufacturing, aluminum is an ideal material for prototyping in CNC machining. It helps to find and solve problems timely and fasten production.

Our efficient, cost-effective, and precise process allows you to enjoy the best results for your CNC-machined aluminum prototypes. Your budget, time, and materials will be matched by our professional engineering team and superior capability in-house.

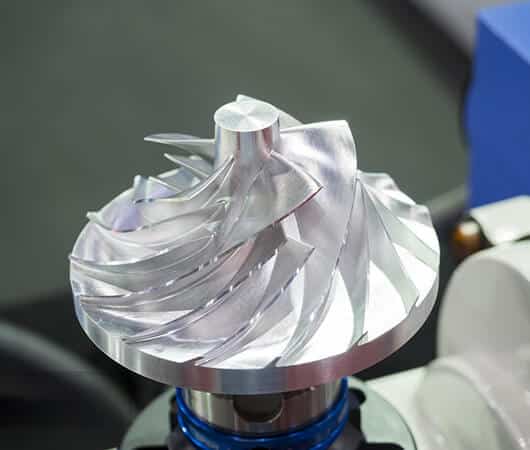

5-Axis CNC Machining Aluminum

If you want to get a machined aluminum part with high accuracy and complex geometries, 5-axis CNC machining may well fulfill your demands. The workpiece can be processed in multiple directions along with cutting in five angles of the axes simultaneously. Our advanced 5-axis CNC machines make it possible to complete all styles of aluminum milling tasks that require machined parts with extreme precision and complex shapes.

One single setup helps to save setup time, fasten the lead time, and increase productivity.

5-axis CNC machines with versatile configurations allow for the complex geometry of aluminum parts.

Workpieces can be machined in a single run, thus quality is improved while error is reduced.

The load on the cutting tool can be reduced by the use of more rigid and shorter tools.

Five Tips to Avoid Deformation in CNC Aluminum Machining

During the manufacturing process, different kind of aluminum has their own internal stresses in the material. Two methods widely used to eliminate inherent stresses respectively are vibration treatment and natural or artificial aging. Another common way is that cut the excess parts ahead of 1-2 hours of natural aging and then move to process.

These methods below can help the thin-walled aluminum parts with poor rigidity to improve the precision in the CNC machining process:

- Use a vacuum table for large sheet material

- Choose a pneumatic or mechanical vise for smaller or odd-shaped parts

- Fill a medium into the interior of the workpiece

- Use suction cups to make clamping force well distributed along with the thin plate

A longer tool may cause the tool deflection on your finished parts. So the shorter tool always is the first choice in CNC aluminum machining. Choosing the correct material and geometric parameters of the tool makes a difference in reducing cutting forces and allowing for excellent chip evacuation.

The aluminum CNC machining processes generally take four steps: rough machining – semi-finish machining – clear corner machining – finishing.

When it comes to high accuracy, it can be taken into consideration that the number of semi-finishing operations should be increased and a uniform machining allowance should be sustained.

- Select the appropriate feed, spindle speed rates, and depth of cut

- Process the front and rear of the workpiece symmetrically

- Machine all cavities of the workpiece with multi-layer

- Drilling should come before milling when machining parts feature cavities

Our Material Grades of Aluminum

If you are preparing to choose aluminum as the material of your part in CNC machining, you may rest assured that you are choosing a kind of material with plenty of advantageous properties. Due to the versatility of CNC machining, it may be a challenge for engineers to target the exact one suitable for specific projects in the list of materials.

Runsom's team of expert designers would like to face challenges, owing to their decades of engineering experience. The material selection will definitely turn out to be perfect and much easier for your expected results. The following are briefs about the main grades of aluminum we have experience with:

│Aluminum 6061

Aluminum 6061 (CNC) is mostly used as the standard grade for CNC machining. Due to its excellent mechanical properties, it has been one of the most popular aluminum alloys among different manufacturing industries.

│Aluminum 6082

Aluminum 6082 (CNC) is a type of aluminum with higher strength than all of the 6000 series alloys and superb corrosion resistance. It can be a substitute for 6061 in many applications. However, designers should take into consideration that it is difficult to produce thin walls.

│Aluminum 6063

Aluminum 6063 is known as an extrusion alloy as well as an architectural alloy. So it is widely found in various interior and exterior architectural applications, and aluminum extrusion applications. It has a medium strength so it may not be suited for applications that need high strength.

│Aluminum 7075

Aluminum 7075 (CNC) is an alloy in which the zinc element accounts for the dominant proportion. Its high strength and good machinability outperform the other aluminum alloys even some softer steels. This grade of aluminum is available for lots of applications with its high-stress or high-performance properties. But it should be noted that 7075 is less ductile, less resistant to corrosion, and relatively more expensive than other grades.

│Aluminum 2024

Aluminum 2024 is an alloy that offers strength at moderate to high levels along with excellent fatigue resistance and toughness. All these features make it most often applied to aerospace and military areas. It’s also commonly found in T3, T4, and T8 tempers and in the annealed state. What needs to recognize is that 2024 has poor resistance to corrosion and high sensitivity to thermal shock.

│Aluminum 5052

Aluminum 5052 is a grade of aluminum alloy easily to be welded that contains high magnesium. Its incredible corrosion resistance, especially to saltwater and salt spray, makes it qualified for marine applications. It also can be used for types of “H” tempers by using cold working to a remarkable degree of hardness. However, it is not suitable for heat treatment.

More than the general properties where an all-purpose aluminum will suffice, aluminum alloys 6061, 7075, and 5052 stand out for their high performance. Stay tuned for more essential facts about CNC precision machining of aluminum 6061, 7075, and 5052.

Our Aluminum CNC Machining Service

Considerate solutions to each project

Dedicated to achieving a more cost-saving, efficient, and accurate process in the manufacturing of your parts, our engineering team will provide you with a complete solution after they evaluate the production cost, and analyze any features difficult to process.

One-stop CNC machining services

In order to produce high-precision dimension parts, we offer integrated services including: 3, 4, 5-axis CNC milling, CNC turning, surface treatment, etc. Our CNC aluminum machining services support customers around the world to boost their business under mutually beneficial cooperation.

![]()

Remarkable lead time & no MOQ

The lead time will be shortened while the profit margin gets improved under the operation of our experts, no matter for manual tasks that consume time or automating tasks that require repetitive runs. We accept all the order that ranges from small to large volume.

Our Strengths Benefit CNC Aluminum Machining

Are you seeking the top support for CNC machining aluminum service in China? We are here to help! Runsom’s team of expert designers would like to face challenges, owing to their decades of engineering experience. We accept all the order that ranges from small to large volume. Contact us today — work together to witness your idea turn into a reality!

What can you get with us:

Why Choose Us for Your CNC Aluminum Machining

15 Years of Experience

You may rest assured that we have an experienced engineering team, advanced production, inspection equipment, and mature management systems.

Save Your Cost

We have optimized the manufacturing process combinations that will greatly save the production cost with the production capabilities of aluminum parts expended.

Quality Reliability

Certificated by ISO9001:2015, we have strict requirements for quality. To meet high quality, we have a sound quality control system and well-equipped measuring devices.

Applications of CNC Machined Aluminum Parts

Automotive

-high strength to weight ratio

Aerospace

-light weight with a large load capacity

Electrical

-good electrical conductivities

Pharmaceutical

-steady chemical property

Food

-steady chemical property

Sports

-high tensile strength, corrosion resistance

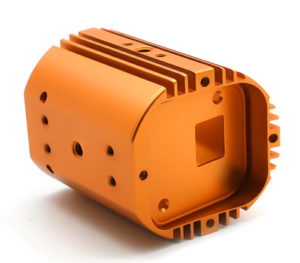

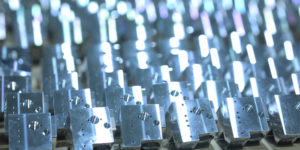

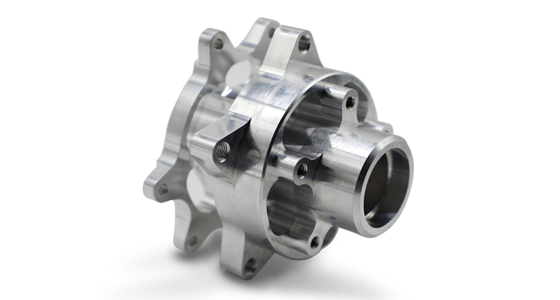

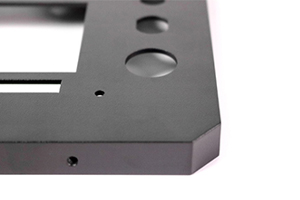

Display of Our CNC Machining Aluminum Parts

Runsom machined aluminum parts are used for automotive, defense, aerospace, transportation, construction, packaging, electronics, consumer goods, and more.

CNC Aluminum Machining FAQs

More than the general properties in which an all-purpose aluminum will suffice, aluminum alloy 6061 stands out for its high performance. So it’s qualified for CNC milling.

The CNC machining process can be improved and simplified by the use of aluminum. Compared to other metals like iron or steel, aluminum is easier to be chipped and shaped, allowing for a shorter manufacturing time.

- Good machinability

- Durability

- Corrosion resistance

- Electrical conductivity

- Recyclability

- Low cost

- Full versatility

- High strength-to-weight ratio

- Anodisation potential

It is a finishing process for aesthetic purposes. The aluminum part is blasted with some form of tiny grinding medium (such as glass) by using pressured air, then leaving a stain or matte finish. This process is used only when there is no high demand for the dimensional tolerances of a part because the main parameters in this process depend on the amount of air pressure used and the size of the medium beads.

It is a finishing process for aesthetic purposes. The aluminum part is blasted with some form of tiny grinding medium (such as glass) by using pressured air, then leaving a stain or matte finish. This process is used only when there is no high demand for the dimensional tolerances of a part because the main parameters in this process depend on the amount of air pressure used and the size of the medium beads. In the electrochemical process, the aluminum is immersed into an acid electrolyte bath and an electric voltage is applied across the cathode and anode. This process effectively converts the exposed metal surface into a corrosion-resistant, electrically non-reactive aluminum oxide coating. Anodizing can be applied to enhance the overall appearance and to color the machined aluminum parts.

In the electrochemical process, the aluminum is immersed into an acid electrolyte bath and an electric voltage is applied across the cathode and anode. This process effectively converts the exposed metal surface into a corrosion-resistant, electrically non-reactive aluminum oxide coating. Anodizing can be applied to enhance the overall appearance and to color the machined aluminum parts. The aluminum part is coated with colored powder by using an electrostatic spray gun charging the powder and spraying it onto the parts. The powder coating. Any overspray can be collected and reused in this process. It is an outstanding finishing method that realizes a combination of aesthetics, durability, and sustainability, greatly improving mechanical properties.

The aluminum part is coated with colored powder by using an electrostatic spray gun charging the powder and spraying it onto the parts. The powder coating. Any overspray can be collected and reused in this process. It is an outstanding finishing method that realizes a combination of aesthetics, durability, and sustainability, greatly improving mechanical properties. Heat treatment is employed to increase the strength and hardness of a specific subset of aluminum alloys, that is the precipitation-hardenable wrought and cast alloys. The mechanical properties of aluminum parts will perform better after heat treatment.

Heat treatment is employed to increase the strength and hardness of a specific subset of aluminum alloys, that is the precipitation-hardenable wrought and cast alloys. The mechanical properties of aluminum parts will perform better after heat treatment.