Who We Are

—"One of the Best Manufacturers of Precision Machining for Prototyping & Production in China"

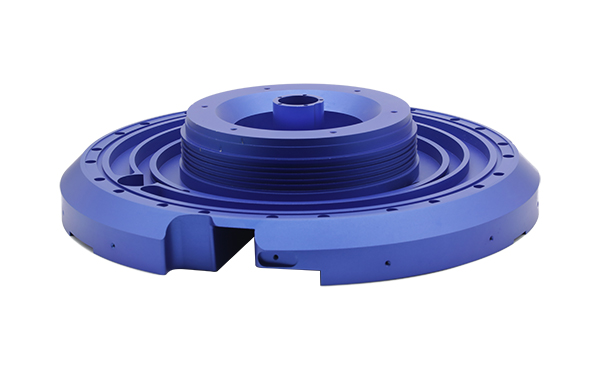

Dongguan Runsom Precision Co., Ltd.(Runsom Precision) is a rapid prototyping manufacturer with the “ISO9001:2015” certification. Headquartered in China, Runsom Precision has more than 10 years of custom CNC machining experience. We specialize in custom CNC machining services from design, rapid prototyping, and complex parts geometry to low or large volume production. Committed to producing high-quality machined parts under your budget and lead time demand, Runsom Precision can take your concepts or designs to reality production in just days with our specialization, quality, and craftsmanship.

Runsom Precision has fully guaranteed the quality of CNC products and customer satisfaction in strict accordance with the provisions of the ISO standards in the regulations of management rules. We partner with organizations around the world to craft precisely machined parts in a variety of certificated materials, including various plastics and metals. Products we created have been widely used in aerospace, medical, automotive, communication, mechanical, electronic, intelligent equipment, toys, and other industries.

What We Can Help

Runsom Precision focuses on CNC milling, CNC turning, Swiss turning, 3D printing, and rapid prototyping. We can also provide sheet metal fabrication services. In addition to numerous selections for machining, we also offer a series of post-processing options to help improve cosmetics or enhance mechanical properties. Our machined parts are generally used by professional engineering companies and original equipment manufacturers worldwide. We serve a vast number of industries including Automotive, Electronics, Optics, Medical, Oil & Gas, Tool & Die, Motorcycle & Bicycle, Dental, Monitoring equipment, and so on.

We offer a fast, efficient, and effective solution for your CNC machining project. This gives you the chance for prototyping tests of form, fit, and function, or for parts production. Evaluation and functional testing of the product enable your product to be optimized before taking it to the market.

Why Choose Us

![]()

1. Incredible Capabilities

Our extensive production capabilities enable us to satisfy all your project requirements from prototype to production.

![]()

2. On-time Delivery

We value punctuality and understand the significance of on-time delivery, so we'll make a suitable production schedule for your project.

![]()

3. Exceptional Experience

You can expect an exceptional customer experience with our expert assistance and prompt response to your inquiries.

How's Our Capability

Runsom Precision possesses a full set of advanced equipment including 3-axis, 4-axis, and 5-axis CNC machines with tolerances of ±0.0005 in and ±0.01 mm, allowing us to produce parts with high precision, complex geometry, and tight tolerance. The materials we use are all ordered from the unified material supplier base, ensuring they are exactly correct and good-quality ones for each product.

We have a rigorous supplier vetting process and only accept top-performing partners to ensure we continue to deliver the highest quality parts to our customers. We also have people on the ground completing regular quality checks of our partners’ facilities. Paired with the rich expertise of our highly skilled machinists and well-trained workforce, our machining center can perfectly match each crucial requirement and specification. Our coordinate measuring machines (CMM) perform a complete inspection to make sure each part is produced exactly to your specifications and generate measurement results quickly.

Quality Assurance

ISO Certified Manufacturer

Our approach strictly adheres to the ISO 9001-certified quality management system. We rely on a set of standardized production processes and work instructions, and employ cutting-edge testing equipment. This allows us to meticulously measure and inspect every stage of production, guaranteeing that your project meets rigorous quality standards. Our specialized manufacturing with quality control guarantees excellent service for customers worldwide.

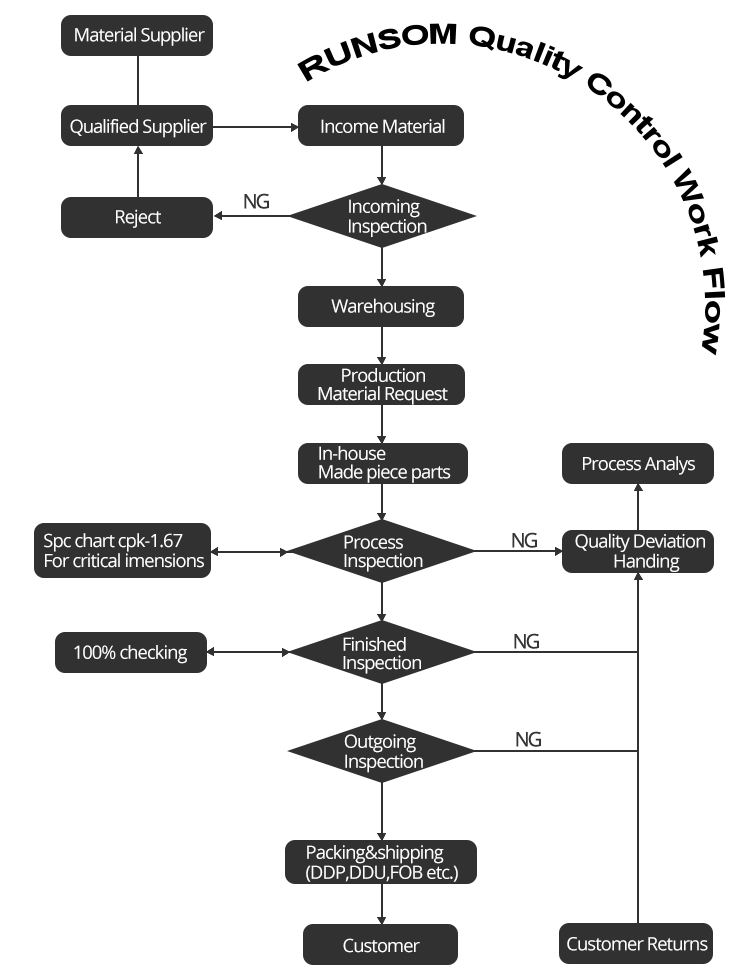

Quality control of production

As your loyal supplier, we have strict manufacturing quality control in all manufacturing processes. To ensure these control processes can be implemented in place, we schedule the following steps:

- Part Design Checking

- Mold Design Control

- Raw material inspection

- Visual inspection

- FAI – First Article Inspection

- PPAP – Production Part Approval Process

- Mold Steel Hardness Inspection

- Mold Electrodes Inspection

- Mold Core and Cavity Steel Dimension Inspection

- Mold Pre-Assembly Inspection

- Mold Trial Report and Samples Inspection

- Pre-Shipment Final Inspection

- Export Product Package Inspection

Frequently Asked Questions

The surface treatment we can do:

- Anodizing

- Hard Anodizing

- Alodine/Chelfilm

- Heat treatment

- Teflon coat

- Chemical conversion coating

- Engraving And Silk Screening

- Plating(Zinc, Nickel, Gold, Silver, Chrome, Oxidize, etc)

- As machined

- Bead Blast

- Powder coating

The material we mostly process:

- Metals

- Stainless Steel

- Aluminium

- Brass

- Bronze

- Copper

- Steel

- Tool steel

- Titanium alloy

- Kovar alloy

- Inconel 625

- Plastics

- POM (Delrin)

- ABS (Acrylonitrile Butadiene Styrene)

- Polyethylene

- Nylon(PA)

- PLA

- PC (Polycarbonate)

- PEEK (Polyether Ether Ketone)

- PMMA (Polymethyl Methacrylate or Acrylic)

- PP (Polypropylene)

- PTFE (Polytetrafluoroethylene)

- Polystyrene

- PVC (Polyvinyl Chloride)

- PEI (Polyetherimide)

- CF(Carbon fiber)

- Others

Ceramic, Carbon fiber, etc.

Our latest technology includes:

- CNC Milling Service

- CNC Turning Service

- CNC Milling and Turning Multiple

- Multi-axis CNC Machining

- Micromachining

- Rapid Prototyping

- Mechanical Parts Design

- Precision Engineering Services

- Parts Assemble

- EDM-Wire Cutting

- Laser Cutting

- Precision Grinding

- Swiss Turning Machining

- Auto-Lathing Turning

- Injection Molding

- Die Casting

- Investment Casting

- Sheet Metal Fabrication

Production Capabilities Minimum Tolerance:

- Outer diameter dimension(turning Process) 0.01mm.

- Outer diameter dimension(centerless grinding process) 0.005mm.

- Outer diameter dimension(step grinding process) 0.005mm.

- Internal diameter dimension(turning process) 0.01mm.

- Center distance dimension(CNC milling process) 0.01mm.

- length, width, high(CNC milling process) 0.01mm.

- surface roughness Ra0.4a.

- Run-out 0.01mm.

- Roundness 0.01mm.

- Flatness 0.01mm.

- perpendicular 0.01mm.

- Cylindricity 0.01mm.

We can generate production drawings based on your current 2D or 3D CAD sketches or samples you provide. Surely, we will sign and adhere to any non-disclosure or confidentiality agreement if your design is confidential.

We respond within 24 hours when receiving an RFQ. If it is delayed, we will notify you as soon as possible.

Please feel free to get a rapid quote right now!

The lead time is normally 2-3 weeks when receiving your complete 2D or 3D CAD models from the order date. Complex parts or large orders will take longer.

We are able to be competent for some urgently needed projects as well. As for shipping, most of our shipments are via Express or by Air, which may take 3-7 days to your door.

In order to accurately and timely quote, we only accept 3D CAD files in STL, SLD, STEP, or IGES format. 2D drawings with reference dimensions must be in PDF, DWG format.

From raw material incoming to product shipment, we control every step to ensure all these are absolutely according to the customer’s requirements. All products should have 4 steps during the whole manufacturing process:

- Raw material inspection.

- In-processing inspection.

- Final inspection.

- Outgoing inspection.

With an ISO 9001:2015 certified manufacturing process, combined with our in-house quality control system and measuring equipment, we ensure problem-free products.

To ensure the high quality of our machined components, we have a detailed quality control system and fully equipped measuring equipment. We guarantee all the dimensions based on the information provided by you. We have confidence in our ability to meet and exceed any reasonable expectations.