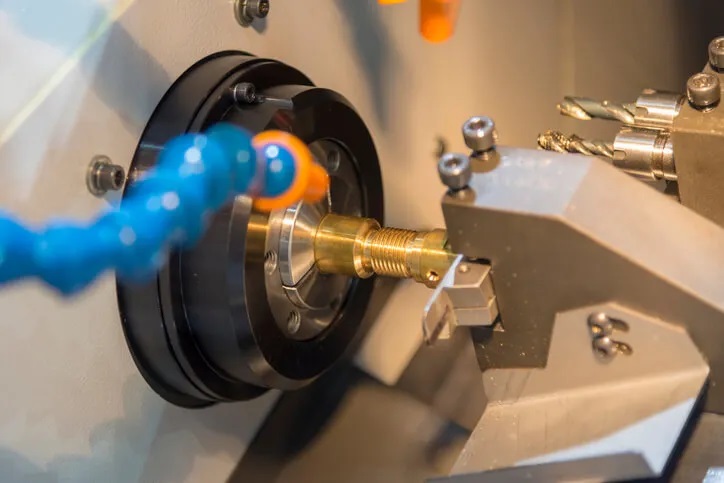

Brass CNC Machining Service

A complete brass CNC machining service for custom parts

Quick-turn brass prototypes and production parts in days

Precision CNC machined parts in grades of brass C260, C360

Brass CNC Machining Services for Custom Parts & Components

Runsom has specialized in brass CNC machining for more than ten years. Our brass machining capabilities ensure you experience the best result of product manufacture by employing the latest brass CNC machining technology and proven expertise. Whether you need one piece of prototype or mass production with quantities in tens of thousands, we will satisfy your demands in any way and promise your parts in high precision and tight tolerance. At Runsom, all kinds of products can be manufactured with all grades and alloys of brass, ranging from pipe fittings to components and no matter how complex or simple it may be. Keeping forging ahead in CNC brass machining, our mission is always to offer our customers flawless parts and components that match their project requirements.

CNC Brass Prototyping

Brass is one of the most popular metal alloys for rapid prototyping, especially used for CNC machining and sheet metal fabrication. Brass is a metal alloy for which copper and zinc are primarily accounted. The proportion of the two significant elements may be correspondently changed to achieve different mechanical and electrical properties. Rapid prototyping can fully use the good properties offered by brass, such as tighter seals for fittings, and can be easily machined and joined. More importantly, it can save production costs and keep strength under high stress.

5-Axis CNC Machining Brass

Brass is usually considered one of the easiest materials to be machined in CNC turning or milling. Its high strength can be maintained even under some cases of extremely harsh conditions. Our 5-axis CNC machine shops have the capability of creating machined brass parts and components that are durable and cost-efficient, particularly creating tighter seals for fittings commonly applied in precision engineering for manufacturing cylinder parts or electronic hardware. The tight tolerance and complex geometry of brass parts would be easily achieved with our precision 5-axis equipment.

One single setup helps to save setup time, fasten the lead time, and increase productivity.

5-axis CNC machine with a versatile configuration allows for the complex geometry of brass parts.

Workpiece can be machined in a single run, thus quality is improved while error is reduced.

The load on the cutting tool can be reduced by the use of more rigid and shorter tools.

Three Tips for Brass CNC Machining

The brass high-speed CNC machining can be realized under comprehensive consideration of tools, parameters, equipment, and conditions.

1. Use cutters with carbide inserts or carbide cutting tools - the removal rate of material and tool life will be enhanced, also the run speed of mills will be increased.

2. Apply the spindle liners in the machine shop - it’s a way to protect the workpiece, device, and operators, minimize the clearance to damp vibration, and reduce the bar whip at a maximum extent, also allow the machine to run at a higher speed, and guarantee the quality of turned or milled brass parts.

3. Make sure the correct programming - it has a significant impact on brass CNC cutting. The right codes ensure spindle speed and operations running at the desired state.

Our Brass Grades for CNC Machining

Brass is mainly composed of copper and zinc, also alloyed with combinations of other metals such as lead, iron, tin, and aluminum to further enhance its properties. Different brass compositions have different characteristics, extremely determining the properties you may need for your project. Therefore, it’s necessary to have a profound understanding of brass alloys. Four main brass grade materials we offer are shown below to help you determine the right one as per your design specification.

Red Brass│Brass C230

Red brass is significantly stronger than yellow brass. Brass C230 can be suited for hot and cold work. It's a versatile alloy, known for its remarkable natural golden appearance and good machinability. Of its excellent resistance to corrosion, and cheaper price than other copper-zinc alloys, it has been widely used for decorative items.

Free Machining Brass│Brass C360

Brass C360 is a zinc-alloyed formulation with the highest amount of lead element, so it has the highest machinability of all copper alloys. With its incredible machinability, the tool wear will be minimized. It can be ideal for parts that need strength or a polished surface finish. A thin protective patina protects C360 from rusting. Also, it can be forged and annealed.

Cartridge Brass│Brass C260

Brass C260 is a metal alloy that consists of 70% copper and 30% zinc. It is known as cartridge brass because it has been used in ammunition cartridges for a long time. This grade of copper alloy is highly ductile and is used in general cases in which all copper alloys will suffice.

If you still have no idea about which brass material is best suited for your CNC machining needs, Runsom just has your answer. We are ready for every challenge and strive for being the best in this industry. Just upload your design file and receive an instant quote, as well as DfM feedback.

Finishes & Post-Processing Options for Brass Machined Parts

Given its inherent properties of electrical conductivity, low friction, and corrosion resistance, CNC machined brass parts generally don't take extra coating anymore. However, if the part is exposed to some elements or the application is cosmetic, some available surface finishes are worthwhile to consider.

As Machined

Brass can be found in most cases that focus on aesthetic purposes because of its natural colors, particularly in ornament applications. A smooth and shiny surface can be achieved by polishing the brass part.

Brass can be found in most cases that focus on aesthetic purposes because of its natural colors, particularly in ornament applications. A smooth and shiny surface can be achieved by polishing the brass part.

Hand polishing, honing, or buffing

Brass can be found in most cases that focus on aesthetic purposes because of its natural colors, particularly in ornament applications. A smooth and shiny surface can be achieved by polishing the brass part.

Powder coat

To enhance the weather resistance of the products, especially the part used for outdoor brass light fixtures, it's often viable to employ a method - powder coating to improve their durability or to add color.

Electroplating

The trick to electroplate brass is to apply the electrical current to coat an object with a thin layer of a metal material such as nickel and chrome. The deposited layer of metal material creates better properties like wear resistance or an appealing appearance that initial brass parts may lack.

Why Choose Us for Your CNC Brass Machining

15 Years of Experience

You may rest assured that we have an experienced engineering team, advanced production, inspection equipment, and mature management systems.

Save Your Cost

We have optimized the manufacturing process combinations that will greatly save the production cost with the production capabilities of brass parts expended.

Quality Reliability

Certificated by ISO9001:2015, we have strict requirements for quality. To meet high quality, we have a sound quality control system and well-equipped measuring devices.

Our Strengths Benefit CNC Brass Machining

1. Precision machining

Precision manufacturing of brass parts in a variety of shapes and sizes with promised accuracy and tighter tolerance. The brass part we produced has a lower deformation coefficient and higher resistance to impact.

2. High-speed machining

Increased productivity by improved removal rate of brass bar stock in turning, milling, and drilling processes with our advanced CNC machining shop equipped with the toughness and powerful features of the latest high-speed machine tools.

3. Efficient machining

The tool wear is minimal as a result of the nearly eliminated formation of chips in our CNC brass machining. We greatly increase the machining efficiency resulting from more durable tools and less friction by the use of brass rod workpieces that are highly compatible with most CNC machining tools.

4. Cost-saving machining

Work with our high-speed brass CNC machining, you can be convinced beyond doubt that your business will be promoted. Your capital investment can be beneficial from a combination of factors, including the high durability of the tools, low frequency of costly tool maintenance and replacement, and relatively cost-efficient material grades of brass.

Applications of CNC Brass Parts

Brass is one of the common materials used in the manufacturing industries relying on its exceptional mechanical properties. At Runsom, we can deliver custom precision machined brass parts for a wide range of industries and applications with a sound grasp of their all standards and specifications.

Bushing

Bearing

Gear

Bell

Handle

Knob

Nut and Bolt

Hinge

CNC Machining Brass FAQs

Brass is a copper-zinc alloy that is easier to machine than aluminum. Brass is far less likely to adhere to tools than aluminum, so it can be machined faster at a lower power. Brass C360 is an alloy with the easiest machinable properties, so this is exactly why it is also referred to as free machining brass.

There are different shapes and sizes of brass, for example, brass rods, brass sheets, and brass tubing. The premise to use brass is to cut and shape it correctly.

1. Cutting brass

For small brass rods or tubing, it’s suggested that use cutting pliers or a hacksaw to cut it; For larger rods, larger cutting machines are necessary.

A handy motorized rotary is most often used to cut brass tubing, rods, and sheets. You are likely to get any shape and size you want because it’s not as hard as some metals like steel.

2. Shaping brass

What you need to do is bend and shape the brass part to meet your application requirements after cutting it. Fortunately, it's easy to shape and bend the brass as well. For example, you can bend and shape a brass wire with a plier.

It could be a bit difficult when it comes to shaping brass sheets. But you may be assured that there are several tools to help do the job easier.

Brass is acknowledged for its low friction coefficient, impact and corrosion resistance, extreme durability, etc. That is why it is often found in a wide variety of applications and industries. Therefore, if you are searching for a reliable and stunning material for CNC machining, brass seems to be a nice choice.

There are lots of brass grades but choosing which one is ultimately depending on the specific requirement for your projects. Still have no ideas about how to choose the right material and the machining operations? Contact us now to check out our CNC brass machining services. Our experts are here to help you to achieve a more cost-saving, efficient, and accurate process in the manufacturing of your parts with a free quote within 24h.

- Use cutters with carbide inserts or carbide cutting tools - the removal rate of material and tool life will be enhanced, also the run speed of mills will be increased.

- Apply the spindle liners in the machine shop - it’s a way to protect the workpiece, device, and operators, minimize the clearance to damp vibration and reduce the bar whip at a maximum extent, also allow the machine to run at a higher speed, and guarantee the quality of turned or milled brass parts.

- Make sure the correct programming - it has a significant impact on brass CNC cutting. The right codes ensure spindle speed and operations running at the desired state.

Work with Runsom for Precision CNC Machined Brass Parts

Runsom, a premier manufacturer of brass parts, excels in brass CNC milling, turning, and drilling. Our state-of-the-art equipment and rich experienced team enable us to deliver you products of the best quality. All of the parts must be examined thoroughly by ISO 9001:2015 before shipping. We continue to forge ahead to offer you an effective solution that saves you time and money on your project.

Request a free quote on brass CNC machining right now!