Runsom is a professional provider of CNC machining services with advanced 3-, 4-, to 5- axis milling centers. We offer custom CNC milling for various industries worldwide. Our precision 3-, 4- and 5-axis CNC milling centers and experienced team guarantee our incredible CNC capacity, enabling us to handle the whole stage of the milling process easily from designing, prototyping, manufacturing, to final transportation.

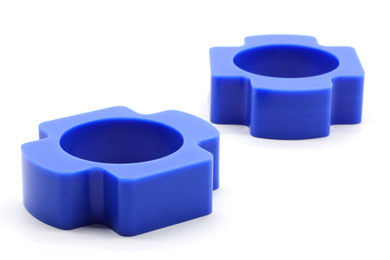

With excellent capabilities and extensive expertise, we can provide top-grade but cost-effective custom CNC machining services from China, including 3-, 4-, and 5-axis milling for high-speed CNC manufacturing and rapid prototyping, and precision CNC turning. Our high-quality milled products are involved in the field of automation design, machine tool machining, medical equipment, lighting parts machining, etc.

What Is CNC Milling

CNC milling is cutting solid plastic or metal material into final precision parts using different axis milling processes. Unlike CNC lathes, CNC mills remove material from the workpiece by rotating and moving a cutting tool, such as a milling cutter, and position the workpiece properly, to create a finished or semi-finished shape.

The multi-axis milling machines realize a versatile, accurate, and repeatable CNC milling process for the production of different features and complex geometries. Take channels, holes, curves, and corners for some examples. Milling can be also used as a perfect way of making tooling for die casting and injection molding.

Our advanced facilities conclude imported 3-axis, 4-axis, and 5-axis CNC mills that are equipped with different tool sets to maximize production efficiency and speed. Send us your inquiry or 3D files online to get an online quote for free now.

How Does it Work

The first step is using CAD software to design a part with desired geometry. Then you can submit your 3D CAD files online and get an instant quote for free. Upon all details having been checked and determined, your digital design will be put into production immediately.

- Design a 3D CAD model

- Convert the CAD model into the CNC machine program

- Start the machining process through the interface or control panel

- Remove block material from the workpiece to get desired shapes

- Conduct the CNC milling operation with high precision

Why Choose CNC Milling

CNC milling is an ideal choice for manufacturing angled shapes, planes, grooves and channels, holes, curves, chamfers, and many other features.

Milling is not only used to manufacture finished parts, but also used to build molds for plastic injection molding and pressure die casting.

CNC milling machines can remove a large number of materials quickly and accurately, and produce good surface finishes at the same time.

CNC milling can machine different parts with a variety of materials. This process can be carried out on any rigid material.

Milling is the most versatile of all available CNC machining processes.

Because no other specialty tools need to be manufactured and no requirements for minimum order quantity, the process is highly cost-effective compared with additive manufacturing.

Minimal setup time makes it possible that CAD files can be converted to finished products in a few hours.

CNC Milling Materials Options

We provide more than 50 types of plastics and metal blocks with different specifications for CNC milling.

Different Types of CNC Mills

Generally, the type of CNC mills is defined according to their number of axes. With more axes, the ability to manufacture complex parts and create cutting angles is enhanced and strengthened.

3-axis CNC milling machines

the cutting tools can travel along the X, Y, and Z axes.

4-axis CNC milling machines

similar to a lathe, add an extra degree of movement by rotating on a vertical axis, allowing to make more complex parts.

5-axis CNC milling machines

the most complete mill, incorporate two extra degrees of movement by adding rotation to the worktable and spindle. Components are processed in a single setup without being moved through several workstations.

Our CNC Milling Capabilities

Expertise

Expertise in CNC machining for over ten years, Runsom can offer a series of custom milling services including thread milling, precision milling, plastic milling, metal milling, etc.

Services

We are forging ahead to provide the top support in the CNC machining field, making sure that each milled part satisfies our clients’ meets and specifications.

Facility

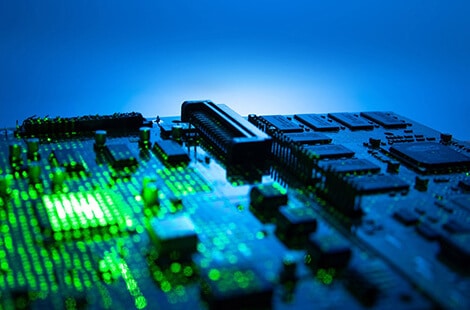

Our factory has equipped with a full set of advanced CNC milling machines like 5-axis CNC milling machines with different tools. To ensure the quality of parts, we employ an on-machine inspection system.

Quality

Our highly skilled engineering team will seek the exact tools and optimize tool paths to produce high-quality milled parts with tight tolerances and a good surface finish.

CNC Milling Surface Finishes

Different surface finishing is available for milling parts, such as painting, anodizing, and chroming. This will enhance function and aesthetic appearance greatly.

Without any surface treatment processing methods, the parts will leave visible tool marks and burrs, which can be completed quickly and cost-saving.

A surface treatment process to obtain a certain degree of cleanliness and different roughness on the surface of the workpiece. The surface after sandblasting is dull and matte.

Many colors(such as black, red, blue, etc.)are available. Divided into Type II (normal) and Type III (hard), Type III is usually thicker than Type II and more corrosion resistant.

The powdered paint is sprayed onto the surface of the workpiece by electrostatic spraying to form a powdery coating, and then the powder layer is cured by heating and baking to level it into a uniform film layer. It is usually used for appearance parts, and a variety of colors is available.

Request an instant RFQ and we will offer you the appropriate surface finish for your project if you still do not see the finish you are looking for.

Why Choose Runsom CNC Milling Services

High Accuracy

We have realized tight tolerance down to +/-0.001″ – 0.005″.

Economy & Efficiency

Precise repeatable production exactly matches per specification, extremely saving your time and production cost.

Material Options

Over 50 metal and plastic materials and a wide type of surface finish for your choice.

High Productivity

With our superior milling machines and optimized milling workflow, you can obtain a physical copy of your digital design in a rapid turnaround.

CNC Milling FAQs

CNC milling starts with designing a digital part with CAD software. Then the file will be converted into CNC readable program code, which can be recognized by a CNC mill and dictates to the mill how to rapidly fabricate parts from raw material blocks.

Different from CNC lathes or turning centers where a stationary cutting tool removes material by making contact with the spinning workpiece, CNC mills cut away block or bar stock by a rapidly rotating cutting tool moving against the workpiece. The tool path is controlled by computer instructions, enabling improved reliability and repeatability regardless of potential human error.

Different milling types can achieve different functions and can be suitable for different applications. Usually, CNC milling services can be divided into the main 8 types of operations:

- Gear Milling

- Thread Milling

- Plain Milling

- Form Milling

- Face Milling

- Angular Milling

- Profile Milling

- Straddle Milling

With its high flexibility and capacity of manufacturing almost all types of irregular geometries and complex parts, CNC milling has become one of the most popular methods for both rapid prototyping and end-use production.

At Runsom, our automatic tool changers can encompass drilling, boring, counter boring, counter sinking, profiling, cutting, reaming, threading, tapping, and other operations completed in the same setup. We can produce almost any shape of CNC components with various tooling and ingenuity in professional milling centers. Parts' dimensions and features decide the selection of multiple-axis machines. And a single setup will ensure the accuracy and quality of components with complex geometry. Multi-axis milling needs complex, skillful, and meticulous programming, so a precision 3D CAD file will reduce our quoting and programming time. Elements such as tolerance, surface finishes, part size, tooling, and material properties will affect the quotation directly. Now upload your CAD file, and get a quote from Runsom.

Our advanced facilities conclude imported 3-axis, 4-axis, and 5-axis CNC mills that are equipped with different tool sets in order to maximize production efficiency and speed.

Yes, it’s. It’s practicable that parts already made using other processes(such as 3D printing and casting) can employ the CNC mill to machine desired features, details, and texture.

CNC milling is used to produce many typical geometry parts with tight tolerances and high accuracy. In the precision CNC milling design process, we recommend typical CNC milling parts including complex planes, curved surfaces, shell parts, connecting rods, propellers, and component housings. However, consumers should also notice that some factors like thin walls, deep cavities, and inner wall cutouts may be not suitable for the CNC milling process.

We provide professional design considerations as follows:

- Avoid Sharp Internal Corners.

- Avoid Narrow, Deep Slots.

- Avoid flimsy shapes.

- A corner radio of 10% or more of wall height is ideal.

- Practical shape as straight edges.

- Weak shapes are difficult to mill, such as long thin shapes and thin walls.

- Visible cutting surface pattern for cutter rotation and movement.