CNC machining is able to manufacture products of any metal or plastic. Its wide application of available materials make perfect selection is a challenge process. We will compare compare the most CNC materials in terms of mechanical and thermal properties, cost and typical applications. Summarized all these information in tables and graphs and provide available CNC materials options with specific details.

Materials selection process

Basic steps of material selection process:

- Define material requirement: including mechanical, thermal, cost, surface finishes and other material requirements. Parts usage environment and components with interaction should be considered.

- Identify candidate materials: confirm some kind of candidate material, which satisfy all or most of your design requirement.

- Select most suitable material: compromise two or more design like mechanical performance and cost. Determine the most suitable material.

You can identify most suitable material for your application with following information, and kee your project on budget.

CNC Material Selection Guideline

In reason of metal and plastic materials has significant diffidence, we will divide these materials into groups and compare their properties. Metals are normally applied for high strength, hardness, and thermal resistance requirement. While plastics are lightweight for chemical resistance and electrical insulation properties.

These materials properties including mechanical strength(as tensile yield strength), machinability (machining ease for CNC pricing), material cost, metal hardness, plastic temperature resistance.

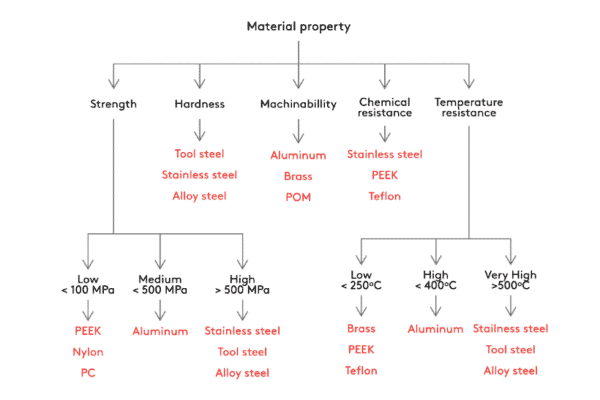

The following graph for identify CNC materials for specific engineering materials:

Metal properties summary

| Material | Grade | Strength | Hardness | Machinability | Cost |

| Aluminum | 6061 | Medium | Medium | Excellent | Low |

| 6082 | Medium | Medium | Excellent | Low | |

| 7075 | High | Medium | Excellent | Medium | |

| 5083 | Medium | Low | Excellent | Low | |

| Stainless steel | 304 | High | Medium | Poor | Medium |

| 316 | High | Medium | Poor | High | |

| 2205(Duplex) | High | High | Poor | High | |

| 303 | High | High | Medium | High | |

| 17-4 | High | Very High | Poor | High | |

| Mild steel | 1018 | Medium | Medium | Medium | Low |

| 1045 | Medium | High | Medium | Medium | |

| A36 | High | Medium | Medium | Medium | |

| Alloy steel | 4140 | Medium | High | Medium | Medium |

| 4340 | High | High | Medium | Medium | |

| Tool steel | D2 | High | Very High | Poor | High |

| High | Very High | Poor | High | ||

| High | Very High | Poor | High | ||

| Brass | C3600 | Medium | Medium | Excellent | Medium |

Plastic properties summary

| Material | Strength | Operating temperature | Machinability | Cost |

| ABS | Medium | 60°C | Medium | Low |

| Nylon | High | 100°C | Poor | Low |

| Polycarbonate(PC) | High | 120°C | Poor | Low |

| POM(Delrin) | Medium | 82°C | Excellent | Low |

| PTFE(Teflon) | Low | 260°C | Excellent | Low |

| HDPE | Low | 80°C | Poor | Low |

| PEEK | High | 260°C | Poor | High |

CNC Metal Alloy Overview

Aluminum alloys

Aluminium alloys have excellent strength-to-weight ratio, high thermal and electrical conductivity, natural corrosion resistance. Which can be easily machined with low cost, and frequently applied as economical option of custom metal parts production and prototyping. Aluminum alloys have lower strength and hardness than steels, while anodizing operation can create a hard and protective layer on metal surface/

Aluminum 6061: most common and widely applied aluminum alloy with good strength-to-weight ratio and excellent machinability.

Aluminum 6082: similer composition and properties as 6061.

Aluminum7075: common application in aerospace industry, excellent fatigue property and high strength and hardness as steel with heat treatment.

Aluminum 5083: higher strength than other aluminum alloys, seawater resistance. Widely applied in construction and marine industry. Excellent choice for welding.

Material Characteristic: Typical density:2.65-2.80 g/cm³, Non-magnetic, anodizing operation.

Stainless steel

Stainless steel has high strength, high ductility, wear and corrosion resistance. Which is easily welded, machined and polished. Various composition determine it can be magnetic or non-magnetic.

Stainless steel 304: as the most common stainless steel, it has excellent mechanical and machinability, corrosion resistance.

Stainless steel 316: another common stainless steel with similar mechanical properties to 304. it has higher chemical and corrosion resistance in saline solutions. Especially apply in harsh environment.

Stainless steel 2205 Duplex: it has highest strength than other common stainless steel, also has excellent corrosion resistance.

Stainless steel 303: it has excellent toughness, but lower corrosion resistance than 304. Widely used in aerospace industry for nuts and bolts.

Stainless steel 17-4: it can be precipitation hardened to high degree as tool steels. Most suitable for high performance application.

Material Characteristic: Typical density:7.7-8.0 g/cm³, Non-magnetic (304, 306, 303), Magnetic(2205 duplex, 17-4)

Mild steel

Mild steel is also called low-carbon steel. In reason of its low cost with good mechanical, machinability and weldability properties, it was applied as general purpose application like: machine parts, jigs, fixtures. However, it is susceptible to chemical corrosion.

Mild steel 1018: as most common used mild steel with good machinability and weldability.

Mild steel 1045: medium carbon steel with high strength and impact resistance.

Mild steel A36: as common structural steel with good weldability, especially for construction applications.

Material Characteristic: Typical density:7.8-7.9 g/cm³, Magnetic.

Alloy steel

Alloy steel contain other element except carbon, in order to improve hardness, toughness, fatigue and wear resistance. Which is susceptible to chemical corrosion.

Alloy steel 4140: it has good strength and toughness, but is not recommended for welding process.

Alloy steel4340: it can be heating treated to high strength and hardness with good toughness, wear resistance and fatigue strength, in addition, it is weldable.

Material Characteristic: Typical density:7.7-7.9 g/cm³, Magnetic

Tool steel

Tool steel has exceptional high hardness, stiffness, abrasion and thermal resistance. It is normally used for tools manufacturing, such as dies, stamps and molds. With heat treatment, it can achieve good properties.

Tool steel D2: it is a wear-resistant alloy with excellent hardness at temperature of 450°C, normally used for cutting tools and dies manufacturing.

Tool steel A2: it is an air-hardened steel with excellent toughness and dimensional stability at elevated temperatures.

Tool steel O1: it is an oil-hardened alloy with high hardness of 65HRC.

Material Characteristic: Typical density:7.8 g/cm³, Typical hardness:45-65HRC.

Brass

Brass has good machinability and excellent electrical conductivity, especially for low friction requirement. Common used in architecture for golden appearance for aesthetic purpose.

Brass C3600: it has high tensile strength and natural corrosion resistance. Wide used for high volume applications with easy machinability.

Material Characteristic: Typical density: 8.4-8.7 g/cm³.

CNC Plastic Overview

ABS

ABS is the most common thermoplastic materials with good machinability, excellent impact strength and high heat resistance. ABS has low density, especially for lightweight applications, widely in injection molding mass production.

Material Characteristic: Typical density: 1.00-1.05 g/cm³.

Nylon

Nylon is also called as polyamide (PA), which has excellent good impact strength, high chemical and abrasion resistance, but susceptible to water and moisture absorption. Nylon 6 and Nylonn 66 are common grade in CNC machining.

Material Characteristic: Typical density: 1.14 g/cm³.

Polycarbonate

Polycarbonate is a thermoplastic with higher mechanical properties than ABS. It is optical transparent, but also can be colored. Widely applied for fluidic device in automotive industry.

Material Characteristic: Typical density: 1.20-1.22 g/cm³.

POM (Delrin)

POM has commercial name as Delrin, it is engineering thermoplastic with highest machinability. POM is the most suitable plastic for high precision, high stiffness, low friction, excellent dimension stability at high temperatures.

Material Characteristic: Typical density: 1.40-1.42 g/cm³.

PTFE (Teflon)

PTFE is known as Teflon, which has excellent thermal and chemical resistance with the lowest friction coefficient. It can withstand temperature of 200°C, and electrical insulation.

Material Characteristic: Typical density: 2.2 g/cm³.

HDPE

HDPE has high strength-to-weight ratio, high impact strength and wear resistance. It is suitable for outdoor application and piping.

Material Characteristic: Typical density: 0.93-0.97 g/cm³.

PEEK

PEEK has high strength-to-wight ratio, thermal stability at wide temperature range and excellent chemical resistance. Which is widely applied in medical and biomedical industry,

Material Characteristic: Typical density: 1.32 g/cm³.