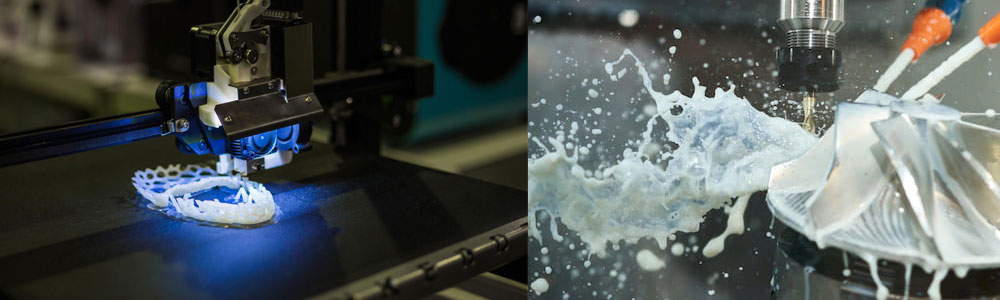

CNC machining is the most common subtractive manufacturing technology, it starts with a solid block of raw materials, and utilize various sharp rotating and cutting tools to remove material, in order to achieve required final shape with high tolerance. CNC machining is widely applied to manufacture low, medium and high volume production. It provides excellent repeatability, high accuracy and various surface finishes with wide range of metal and plastics.

3D printing or additive manufacturing produce parts by several layer of material adding. It doesn’t need any special tooling or fixtures. Its process can be divided into SLS or FDM for plastics and DMLS for metals.

Perfect Technology Selection

There are several simple guideline for manufacturing process decision between CNC machining and 3D printing. As we know, any parts can be produced with limited effort by subtrative way should select CNC machining. Otherwise, 3D printing can make sense in following case:

- Traditional methods are unable to produce, especially for high complex geometries.

- Fast turn-around time is critical.

- Low-cost is essential, especially for small volume less than 1o.

- Materials are not easily to machine, like superalloys or flexible TPU.

CNC machining is able to provide higher dimensional accuracy and better mechanical properties in each dimensions, while in small volume production, its cost will be higher. In high quality production, neither CNC machining nor 3D printing can be cost-competitive option. Traditional forming technology like investment casting, injection molding are more economical.

Process Characteristic

Dimensional accuracy

CNC machining provides higher tolerance and excellent repeatability for different parts size. In reason of cutting tools shape, internal corners have radius, while external surface can be machined as sharp edges and thin.

Different 3D printing system has various dimension accuracy, all 3D printers can produce parts with good tolerances. Once you need tighter clearance, we can print oversize dimension, then machined in post processing operation. The minimum wall thickness of 3D printing is limited by end effector size, such as nozzle diameter in FDM, laser spot size in SLS. Since 3D printed parts are created layer by layer, it is visible to see layer lines in parts, especially on curved surface.

| Tolerance | Minimum wall thickness | Maximum part size | |

| CNC | ± 0.025-0.125mm | 0.75mm | Milling: 2000×800×1000mm Turning:500mm diameter |

| SLS | ± 0.300mm | 0.7-1.0mm | 300×300×300mm |

| FDM | ± 0.200mm | 0.8-1.0mm | 900×600×900mm |

| SLM | ±0.100mm | 0.40mm | 230×150×150mm |

| DMLS | ±0.100mm | 0.40mm | 230×150×150mm |

Materials

CNC is widely applied for metal matching, it also can be used for thermoplastics, acrylics, softwoods and wax machining. CNC machining parts have great mechanical and thermal properties with fully isotropic. Common CNC materials:

Plastic: ABS, Nylon, PEEK.

Metal: Aluminum, Stainless steel, Titanium, Brass.

3D printing is mainly applied for plastics, less extent for metal. 3D printing materials are wide with different physical properties. TPU and superalloys always manufactured with 3D printing technology. Common 3D printing materials:

Plastic: Nylon, PLA, ABS, ASA, TPU.

Metal: Aluminium, Stainless steel, Titanium.

Parts complexity

In CNC machining design, we should consider some design limitations, such as tool access and clearance,holding and mounting points, and inability of square corners manufacturing. In this situation, there are some geometries cannot be produced CNC machining, even with 5-axis CNC machines. For side features, we need to rotate parts direction, this will add positioning time and labor time in process, in some case, custom jigs and fixtures will be needed. All these items will increase the final cost.

3D printing, comparing to CNC machining, has few geometry limitations. Support structures are required in most technology, which will be removed in post processing. The ability of high complex geometries production is the key strength of 3D printing.

Manufacturing process

In CNC machining, operators or engineers will consider tool selection, spindle speed, cutting path and parts positioning at first. All these factors will impact final parts quality and processing time greatly. This manufacturing process is labor intensive, in reason of all set up are manual. After machining process, these components are ready for post operations.

In 3D printing, operators only need to prepare digital file with orientation and added support, then send it to printing machines. Which required little human intervention. Once printing finish, we need manual cleaning and post processing

Post processing

There are various post processing methods for CNC machining and 3D printing part, in order to improve parts functionality and aesthetics. Most common post processing technology including:

CNC machining: bead blasting, anodizing, powder coating.

3D printing: media blasting, sanding, polishing, micro-polishing, metal plating.

Technology selection experience

We need to follow the rules to select the right technology for your parts production:

- CNC machining is most suitable for medium to high volume production(1-500) with simple geometries.

- 3D printing is best for low quantity and complex geometries.

- For metal parts, CNC machining is more competitive with geometries limitation.

- Once quantity is more than 500 parts, other forming technologies are more suitable.