What is FDM

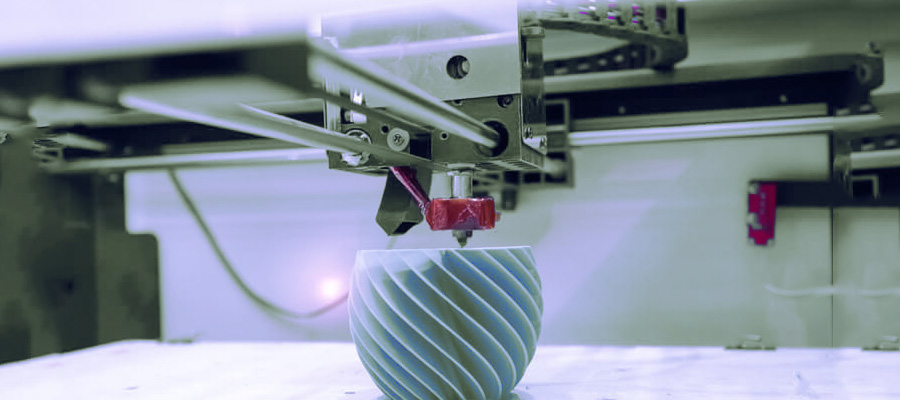

FDM is abbreviation of Fused Deposition Modeling, which is an additive manufacturing process belong to material extrusion family. In FDM process, melted material is deposited selectively in a determined path layer by layer. These materials are thermoplastic,polymers with a filament form.

FDM is the most widely 3D printing technology, it is the first technology in 3D printing. We will introduce the basic principles and key aspects of this technology.

How FDM Work

FDM manufacturing process:

- Thermoplastic filaments is loaded into FDM printer firstly, as the nozzle reach the desired temperature, the thermoplastic melt will be fed to the extrusion head and melt in the nozzle.

- The extrusion head has 3-axis system with movement of the X, Y and Z directions. All melted material is extruded in thin form, and deposited layer-by-layer in predetermined location. Then all materials will cool and solidify, sometimes, we can add cooling fans on the extrusion head to accelerate cooling process.

- Multiple passes is required to fill areas. Once a layer is finished, the build platform will move down and a new layer is deposited. Repeat this process until the final part is complete.

Characteristic of FDM

FDM Parameter

Most FDM machines allow the process parameter adjustment, such as nozzle temperature, build platform temperature, build speed, layer height and cooling fan speed. All these parameter are set by operators.

For the designers, the most important parameter is build size and layer height.

The build size of desktop FDM is common 200×200×200 mm, while industrial is 1000×1000×1000 mm. The desktop is preferred for cost reducing, a big model can be separate into small parts and assembly later.

FDM typical layer height is between 50 to 400 microns, it can determined in order details. The smaller layer height will have smoother surface and accurate curved geometries, while the large height will produce faster with a lower cost. Our most common layer height is 200 microns.

Warping

Warping is the most common defect in FDM. As the extruded material will cool in solidification process, its dimensions will decrease. Different printed sections cool at different rates will cause the buildup of internal stress. This will pull up the underlying layer, give rise to warp. We can prevent warping form technology ways, such as monitoring temperature of the build platform and chamber in FDM system, increasing the adhesion between parts and the build platform.

In addition, we also can optimize our design to reduce warping probability.

- Avoid large flat area once possible. In reason of it is more prone to warping.

- Avoid thin protruding features. Once necessary, add sacrificial material at thin the features edge to increase touching area of the build platform.

- Add fillet to your design and avoid sharp corners, replace with rounded shapes.

- Different materials in one parts are more susceptible to warping, ABS is more sensitive to warping than PLA or PETG. ABS has high glass transition temperature and high thermal expansion coefficient.

Layer Adhesion

It is very important in FDM process for good adhesion between deposited layers. Once molten thermoplastic is extruded through nozzles, it will press against the previous layer. This high temperature and pressure will re-melt previous layer surface and bond the new layer with previous printed part.

We should notice that bond strength between different layers is lower than material basic strength. This means FDM parts are inherent anisotropic, the Z-axis strength is smaller than X-Y plane. So in FDM designing process, the part orientation is very important.

As molten material is pressed on the previous layer, its shape are formed into oval. FDM parts surface is wavy, ever for low layer height. Small features like holes or threads need post processing after printing.

Support Structure

Support structure is essential for overhanging geometries in FDM technology. It is required to support melted thermoplastic, which is difficult to deposit on thin air. Supporting area will have lower surface quality than the rest area, so we recommend to minimize the requirement of support structure. Support structure is normally printed with the same material as part. There is also dissolve support materials, which can improve surface quality significantly, but increase the final overall cost.

Infill & Shell Thickness

FDM is not usually applied for fully solid parts, in order to reduce printing time and save materials. We will apply the shell with several perimeter passes, and fill the interior with infill with a low-density structure. Infill and shell thickness will affect parts strength greatly.

FDM Common Materials

FDM has wide range of available materials, it including commodity thermoplastics like PLA and ABS, engineering materials like PA, TPU and PETG, high-performance thermoplastics like PEEK and PEI.

FDM materials will affect the mechanical properties and accuracy. We summary the common FDM materials as following:

| Material | Characteristics | |

| Advantages | Disadvantages | |

| ABS | Good strengthGood temperature resistance | Susceptible to warping |

| PLA | High visual qualityEasy printing | Low impact strength |

| Nylon (PA) | High strengthWear and chemical resistance | Low humidity resistance |

| PETG | Food safe gradeGood strengthEasy printing | |

| TPU | Very flexible | Difficult to high accuracy |

| PEI | Excellent strengthFire and chemical resistance | High cost |

Post Processing

FDM parts surface can be finished to different standard by various post processing methods, like sanding, polishing, priming and painting, cold welding, vapor smoothing, epoxy coating, metal plaiting. Check the post processing of FDM here.

FDM Benefits & Limitations

FDM Benefits:

- FDM is a cost-effective way of custom thermoplastic parts production and prototyping.

- FDM has short lead time and technology availability.

- Wide thermoplastic materials for prototyping and non-commercial functional applications.

FDM Limitations:

- FDM has the lowest dimension accuracy and resolution. It is not suitable for parts with intricate features.

- FDM parts have visible layer lines, post processing is needed for smooth surface finish.

- FDM parts have inherent anisotropic because layer adhesion mechanism.