Custom Die Casting Solutions for Your Manufacturing Needs

At Runsom Precision, we can execute a variety of aluminum die casting processes tailored to your specific project requirements, ensuring that your part is well-suited for its operational environment. Our custom die casting capabilities cater to manufacturers seeking unique and highly functional designs. Our team of experts will work with you to make the most suitable solution for your project.

Runsom Precision functions as your all-in-one die casting solution. We take on the role of sole accountability, managing everything from initial design support to precision machining, metal finishing, and final assembly.

What is Die Casting?

The process of die casting involves shaping metal. This is achieved by pouring molten metal into a mold, allowing it to cool and harden in the shape of the mold’s interior dimensions. The resulting components boast intricate shapes, durability, and precise fits suitable for functional applications. Die casting stands as one of the foremost methods for crafting parts with exceptional dimensional stability for a wide array of uses.

In die casting, components are mass-produced from a range of metal alloys, such as aluminum, zinc, copper, brass, and bronze alloys.

Following the die-casting process, components can undergo further refinement through CNC machining. Additionally, surface finishes are often applied to ensure adherence to stricter critical-to-function tolerances.

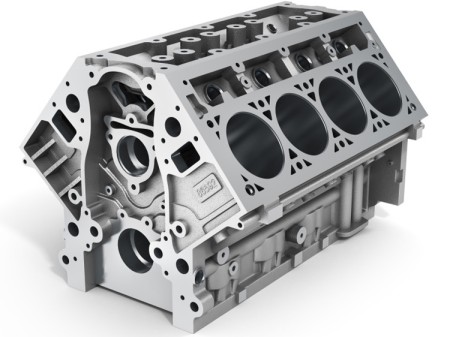

Die-cast parts find widespread use in diverse industries including automotive, aerospace components, power equipment, lighting, firearms, and various other sectors.

The Die Casting Process

Similar to injection molding, die casting necessitates the creation of a mold tool, known as a die, which may feature one or multiple cavities. This method is suitable for softer alloys like aluminum and zinc due to their comparatively lower melting temperature.

In die casting, molten metal is injected into a die cavity, conforming to the part's shape and solidifying in place before extraction. Depending on the project scale, die casting can involve low- or high-pressure techniques, utilizing a ladle or plunger for metal deposition. This process can create intricately complex, tight-tolerance parts repeatedly at significantly high production volumes.

Contemporary die casting techniques such as squeeze casting and semi-solid metal casting yield high-quality parts for nearly every industry. Die casting companies often specialize in casting aluminum or zinc, with aluminum accounting for approximately 80% of die cast parts.

Die Casting Materials

Typically, die casting employs non-ferrous alloy materials due to their low melting point and excellent dimensional stability. Our primary die casting materials available include aluminum alloys and zinc alloys.

Aluminum Die Casting

Die cast parts are most commonly crafted from aluminum alloys. The higher melting point of aluminum may necessitate a cold chamber casting process. Cast aluminum components are renowned for their exceptional strength-to-weight ratios, dimensional stability, and a broad array of finishing options.

Engineers and designers have a wide selection of alloys to choose from for their aluminum casting parts. At Runsom Precision, we provide a wide variety of aluminum die casting alloys, including:

A360

A380

A383 (ADC12)

A390

A413

Zinc Die Casting

Zinc, known for being the easiest material to cast among die casting metals, is commonly utilized in hot chamber processes. Molten zinc exhibits exceptional casting fluidity and boasts a lower melting point, enabling the production of parts with thinner walls, intricate features, and precise tolerances due to its strength and stiffness.

The lower melting point of die casting zinc alloys facilitates rapid cooling and solidification of the casted parts, leading to the quickest production rates among die casting materials. Zinc die castings demonstrate superior strength, toughness, and dimensional stability compared to injection molded plastics.

At Runsom Precision, we provide the most popular varieties of zinc alloys:

Zamak 2

Zamak 3

Zamak 5

Zamak 7

The selection of the material for die casting is based on the intended application of the product. For example, cast aluminum parts are frequently employed in aerospace or automotive applications where corrosion resistance and weight reduction play pivotal roles. Should you have a specific material preference, reach out to us!

Die Casting Surface Finishes

The final stage of precision die casting involves post-processing and finishing. This phase uses finishing techniques to eliminate surface defects, enhance chemical or mechanical properties, and elevate the cosmetic appearance of the products. There are five distinct surface finish options we offer for die cast parts:

If you don't find the finish you require, simply submit an RFQ, and our partner shops will explore suitable finishing processes for your needs.

Die Cast Parts Applications

The versatility and significant production capacity of die casting make it suitable for a wide range of applications and industries. It plays a critical role in the creation and manufacturing of numerous modern products, spanning from aerospace structural components to electrical enclosures.

At Runsom Precision, we have delivered manufacturing solutions tailored to diverse industrial needs. We provide top-notch die cast parts to customers across various industries at competitive prices.

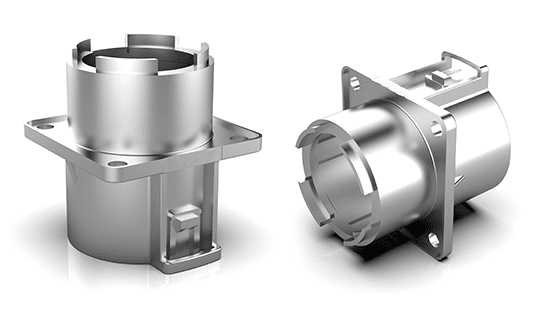

Hubs

Impellors

Manifolds

Gear Boxes

Gear Cases

Hydraulic Cylinders

Fans Blades & Hubs

Pistons

Oil Pans

Valve Bodies

Valve Housings

Pump Components

Pressure Housings

Marine Components

Covers

Cooling Fins

Air Cylinders

Compressors

Electrical Boxes

Aluminum Housings

Electrical Transmission Equipment

Start Your Die Casting Project Today

For projects requiring intricate shapes, multiple components, precise dimensional accuracy, or corrosion resistance, we offer tailored casting methods to suit your needs.

To learn more about our custom die casting processes and capabilities or obtain a rapid quote, reach out to us today.

Die Casting FAQs

The hot chamber and cold chamber die casting processes each possess distinct qualities.

Hot chamber die casting serves as an efficient option for tin, zinc, and alloys characterized by lower melting points. Conversely, the cold chamber die casting process is well-suited for metals with high melting points and corrosive properties.

Cold Chamber Die Casting

In cold chamber die casting, machines are utilized for aluminum or zinc alloys with high melting points or corrosive properties. This method involves transferring metal by ladle, either manually or automatically, to the shot sleeve. The injection piston then compels the metal into the die. This process minimizes the contact time between the hot metal and the injector components, thereby contributing to an extended operating lifespan.

Hot Chamber Die Casting

Hot chamber die casting machines are predominantly used for zinc alloys, copper, lead, and other low melting point alloys. Hot chamber die casting facilitates faster cycling production, intricate cast-in detailing, reduced porosity, and increased waste reduction, while also offering extended service life due to the lower melting points of the alloys.

Metals containing iron, such as carbon steel, alloy steel, and stainless steel, have the potential to rust. While it is feasible to die cast these metals, their tendency to rust makes it relatively rare.

Non-ferrous metals like aluminum and copper hold minimal to no iron content, thus preventing rust formation. However, these metals can still corrode, with susceptibility to corrosion dependent on the specific working environment.

There is a wide array of metals and alloys suitable for die casting projects. Commonly utilized metals include zinc, aluminum, and magnesium. Additionally, copper, brass, tin, and lead can be chosen for custom casting parts. However, the selection of the best metal can be challenging as each alloy possesses distinctive physical characteristics, as well as advantages and disadvantages.

If the task of selecting the optimal metal presents a challenge, the assistance of a custom die casting parts manufacturer, such as Runsom Precision, can be invaluable.

Our expertise extends to CNC machining additional features onto cast parts, including engraving and minor details.

Die-casting stands as the ideal choice for crafting non-ferrous metal products in a relatively short turnaround. With the use of reusable molds, this process guarantees rapid production. It also offers versatility in developing products of diverse sizes and shapes.

However, die casting may not be the optimal solution for every project. One drawback of die casting is its high mold cost. At Runsom Precision, we provide an extensive array of metal casting services, including:

Investment casting

Rapid prototype casting

Sand casting

Lost foam casting

Lost wax casting

Centrifugal casting

Permanent mold casting

Certain projects might find metal stamping or forging more advantageous than die casting. The selection relies on numerous factors, such as the size, mechanical properties, and geometry of the part.

Advantages of Die Catsing

- Complex Geometry

Die casting enables the reliable production of custom parts with intricate geometry and thin walls, ensuring durability and dimensional stability. - Strength

The absence of welding in the manufacture of die-cast parts means that their strength is determined by the material itself. Consequently, metal die-cast parts exhibit greater strength than plastic injections, resulting in a longer lifespan. - Dimensional Accuracy and Stability

When molten metal is injected into a die, it maintains its shape and internal dimensions, ensuring that each finished part fills the mold, resulting in accuracy and consistency across all parts. - Multiple Finishes Available

Die-cast parts can be easily plated and finished with either a textured or smooth exterior. Additionally, these finishes can protect from corrosion while enhancing the aesthetic appearance. - Simplified Assembly

For parts requiring assembly with other components, studs can be attached or holes drilled to facilitate fastening.

Disadvantages of Die Catsing

- Tooling Cost

Although the per-piece cost of die-cast parts is relatively low, the initial investment required for tooling dies and maintenance costs is considerable. - Not Suitable for Low Quantities

Due to the high upfront tooling costs, die casting is not cost-effective for low-volume production runs. It is recommended to consider die casting only for quantities exceeding 1000 units. - Lead Times

The various preliminary steps, such as addressing DFM concerns, tool design, tool manufacturing, and sample creation, contribute to longer lead times, often spanning several weeks before production commencement. As a result, die casting is considered one of the slower manufacturing processes to ramp up compared to others.

Our team of experts will closely collaborate with you throughout the entire process, offering recommendations and options to ensure the best possible turnaround while meeting your unique requirements.

Your Ultimate Choice for Custom Die Casting Services

At Runsom Precision, we employ a blend of traditional and state-of-the-art die casting processes to create components with reliability, exceptional strength, and precision, suitable for a wide range of industries and applications. With the latest die casting machines and technology, we fabricate top-notch, on-demand parts in line with product specifications.

Runsom Precision stands as your premier source for precision aluminum and zinc die cast parts and components, offering in-house design and engineering solutions for your tool and die manufacturing requirements.

Get in touch with us today to discover more or to request an instant quote.