When it comes to making aluminum parts, there are different ways to do it. Casting and forging are two common methods used to create aluminum components for different industries. However, cast aluminum and forged aluminum boasts different properties and benefits for specific applications. Aluminum casting is typically more versatile and affordable, while aluminum forging offers superior strength and resistance to wear.

Therefore, to make an informed choice, it’s necessary to know the differences between them and the strengths of each for your project’s requirements. Let’s move on to learn more about these alloys to find out.

Cast Aluminum

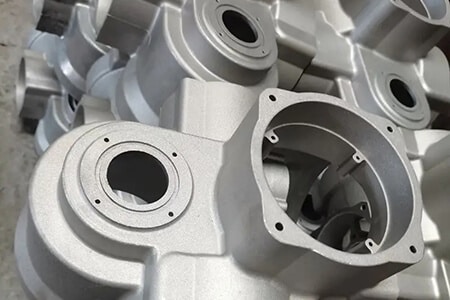

Cast aluminum is created by melting aluminum and pouring it into a hollow mold that matches the shape of the part. Once the aluminum cools and solidifies, the desired part is obtained. The mold can be made of different materials like sand, metal, or ceramic. There are different types of casting methods, including die casting, sand casting, investment casting, and permanent mold casting.

This process is cost-effective and commonly used in manufacturing. The end result is a lightweight alloy that can be easily machined or shaped into different forms. It’s also highly durable and resistant to corrosion, making it ideal for outdoor applications like roofing or window frames.

Advantages

Cast aluminum alloy is highly versatile and has several beneficial properties. It is easy to cast, lightweight, resistant to corrosion, and heat, and can be easily welded. It is commonly used to make complex-shaped parts that do not require extremely high strength, such as aircraft, instrument housings, motor housings, engine pistons, cylinder blocks, and fan blades.

Castings have an advantage over forgings as they can be made into intricate shapes that would be difficult for forgings to achieve. Moreover, forgings are generally more cost-consuming because they require additional finishing operations. However, despite the higher cost, forgings offer significant benefits in terms of reliability, safety, and reduced risks of component failure. These factors are crucial considerations when choosing between castings and forgings.

Forged Aluminum

Forged aluminum undergoes a more complex process compared to cast aluminum. In this method, pure aluminum alloy is heated until it melts and then shaped under high pressure to achieve the desired form and size. This results in a much stronger product that can withstand higher temperatures and pressures without breaking. Common aluminum forging alloys include 6061, 6063, and 7075. It is a versatile material used in various industries, including automotive, aerospace, tools, cookware, and furniture.

Forging helps eliminate defects and enhances durability and toughness by optimizing the microstructure. It also improves the mechanical properties compared to castings of the same material due to the preservation of the metal’s complete structure.

Aluminum forging is ideal for applications that require a metal with both performance and safety while maintaining lightweight for speed or energy efficiency. In machinery where important parts are subjected to high loads and severe working conditions, forgings are primarily used in addition to rolled plates, welded parts, or profiles with simple shapes.

Advantages

Forging is a process that allows the shaping of alloys made from metal and other additive powders. These alloys are in powder form because their constituent elements cannot be melted and cast successfully. The powders are consolidated into solid form using thermomechanical energy.

After consolidation, deformation processes like forging are used to further shape these materials while they are solid. This helps create more useful and efficient forms, reducing the cost of using these expensive materials. By forging, materials can be prepared to meet the demands of future design challenges by ensuring their capability and usability.

When components need to have maximum properties and durability during service, and when minimizing weight and mass is crucial to avoid costly or catastrophic failures, forged products are the preferred choice. While other processes may claim to have “wrought properties,” only the forging process can consistently and reliably deliver them.

Cast Aluminum vs. Forged Aluminum: How to Choose the Right One?

Aluminum forging and casting are two different manufacturing processes. Castings involve melting the aluminum alloy, pouring it into a mold, and letting it solidify. Forgings, on the other hand, shape the material while it remains in a solid state. These processes result in end products with different characteristics.

Determining which process is best for your project depends on specific priorities, such as the need for complex shapes, large sizes, or high levels of strength. Let’s explore the key differences between these processes in terms of mechanical properties, material combination, manufacturing process, and other important aspects:

1. Chemical Composition

Forged aluminum alloys can be made from alloys like Al-Si-Mg-Cu and Al-Cu-Ni-Fe. Some commonly used forged aluminum alloys are LD2, LD5, LD10, and others. These alloys have small amounts of various alloying elements.

As for cast aluminum alloys, there are four types: Al-Si, Al-Cu, Al-Mg, and Al-Zn series. The Al-Si alloy, also called silicon aluminum alloy, offers the best balance of casting performance and mechanical properties among cast aluminum alloys.

In general, forged aluminum alloys have a higher density, as well as higher tensile strength and fatigue resistance.

2. Manufacturing Process

Forged aluminum requires multiple complex processing steps, including die forging, stretching, and cutting. This eliminates the defects found in casting methods and results in higher hardness, stable mechanical properties, and enhanced reliability and durability.

On the other hand, cast aluminum is produced through an injection molding process that involves casting, injection, cooling, etc. This method has higher production efficiency but relatively poorer mechanical properties, with a tendency for deformations and defects.

3. Mechanical Properties

Forged aluminum alloys undergo multiple deformation processes during manufacturing, which refine the metal grain structure. As a result, forged aluminum parts have higher mechanical strength, toughness, and ductility. They also exhibit excellent corrosion resistance, making them ideal for manufacturing high-quality automotive and aerospace components that need to withstand loads.

On the other hand, cast aluminum alloys, despite their high production efficiency, are prone to thermal cracking under pressure. Additionally, the processed products have lower strength and higher brittleness, making them more suitable for low-strength and low-cost applications.

4. Strength

When aluminum forgings are heat-treated, they exhibit excellent mechanical properties that give them a superior strength-to-weight ratio compared to aluminum castings. Additionally, forging eliminates the presence of porosity. Moreover, heat treatment can further enhance the strength of aluminum forgings. This increased strength results in improved performance and a longer lifespan for aluminum forgings.

5. Durability

Forged aluminum is stronger and more durable compared to cast aluminum. It is less prone to cracking or breaking and offers better resistance against corrosion, wear, and tear.

6. Cost

When choosing a manufacturing option for a particular application, cost is an important factor to consider. The overall cost depends on the specific method used. In general, aluminum casting is less costly than forging because forging requires more time and labor to make. For medium to large production runs, aluminum forging can be the most cost-effective option.

7. Surface Finish

When aluminum is forged, it often needs additional steps to refine and complete the product according to specific requirements. On the other hand, cast aluminum typically provides a finished product that requires minimal surface finishing.

However, certain aluminum forging alloys, such as 6061, have excellent anti-corrosion properties even without any surface finishes needed.

8. Flexibility

Not all aluminum components can be forged, but compared to casting, aluminum forging provides greater flexibility to accommodate new design suggestions from clients.

The table below provides a summary of the main differences between forged aluminum and cast aluminum based on several main characteristics.

| Features | Forged Aluminum | Cast Aluminum |

| Chemical Composition | Al-Si-Mg-Cu alloy and Al-Cu-Ni-Fe alloy | Al-Si series, Al-Cu series, Al-Mg series, and Al-Zn series |

| Structural Integrity | Far superior in strength | More porous and prone to breakage |

| Durability | Excellent | High |

| Tolerance | Not suitable for complex shapes | Can achieve a high level of detail and tight tolerances |

| Product Size | Limited in size and thickness capabilities (larger sizes are more challenging) | Compatible with various sizes |

| Secondary Operations | Usually requires additional operations to refine and finish the product | Provides finished product that requires minimal post processing |

| Cost | More cost-effective for medium to large production runs | Generally less expensive than forging, but it depends on the specific casting method used |

Conclusion

Both cast and forged aluminum offer unique advantages in metalworking projects. Castings are typically more affordable and versatile, while forgings provide superior strength and resistance to wear. The choice between the two depends on the specific priorities of your project.

If you prioritize low cost, the ability to use exotic alloys, and the need for complex shapes, while still being strong enough for outdoor use, cast aluminum would likely be the preferred choice. On the other hand, if you require an alloy with exceptional strength and structural integrity for heavy-duty applications such as construction or automotive parts, forged aluminum may be the better option. Ultimately, whichever type of aluminum you choose, ensure that it aligns with your specific needs and requirements!

Discuss Your Machining or Casting Needs with Runsom Precision

At Runsom Precision, we have more than 10 years of experience in aluminum manufacturing services. We specialize in providing custom fabricating services such as aluminum CNC machining, metal casting, and secondary processing. From the initial design to the final fulfillment, we offer hands-on assistance to ensure that you receive high-quality products that meet your needs. With our mature quality control and inspection system, you can be assured that your parts will be delivered with tight tolerance and exact specifications. Reach out to us today to get an instant quote for a custom solution for your aluminum products!

Other Articles You May Be Interested in: