CNC Metal Machining

Work with our state-of-the-art CNC metal machining services

A premier choice for CNC metal prototyping and end-use custom metal parts

A wide range of metals and alloys along with comprehensive machining processes

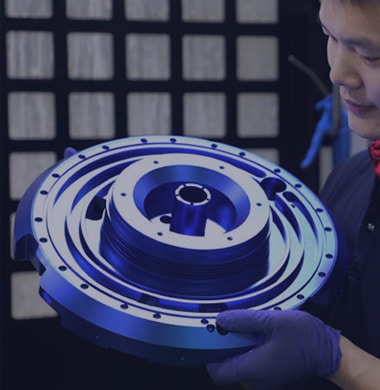

Runsom excels in CNC metal machining for more than ten years paired with our highly skilled engineering team and machinists. Our well-equipped facilities enable the incredible capability in-house, micron tolerance, and intricate geometry in CNC metal machining.

CNC Metal Machining Supplier | Custom Metal Parts Manufacturer

CNC machined metals are universally applied to every major industry from medical to aerospace. CNC metal machining is popular in the mechanical manufacturing industry for tight accuracy, high quality, and great efficiency. The CNC metal machining process involves different machining processes, such as CNC turning, milling, drilling, EDM, and wire EDM. The desired size, shape, and surface finish of the part can be formed through the process of removing metal material with cutting work.

At our facility, we pride ourselves on offering a diverse array of post-processing and secondary operations tailored to suit your specific needs. Our comprehensive metal machining services are adept in working with various materials, including magnesium, zinc, brass, steel, and stainless steel, with particular expertise in CNC aluminum machining. We guarantee that our CNC machined metal parts and components will align seamlessly with your product designs or drawings and files, providing both one-off prototypes and end-use custom parts through our advanced CNC metal machining processes.

Understanding How Metal CNC Machining Works

In CNC machining, a CNC machine carries out operations under a specific set of codes that contains a list of instructions on how to remove the metal materials to the desired geometry, size, and surface finish. The multi-process machining of a workpiece after a single setup starts with an automatic tool change function in the tool storage of CNC machine tools.

The machine tool is under the control of the CNC control system which can make tools, tooling, spindle speed, feed, etc change automatically. Thus, the part can be machined by milling, boring, drilling, and other processes consistently, significantly lowering the auxiliary setup time, such as measuring and machine tool adjustment, and the workpiece clamping. It’s ideal for repeatable tasks with high accuracy and tolerance.

Why Choose CNC Machining for Metal Parts

Choosing CNC for metal machining is ideal for dealing with small runs of metal parts, particularly for prototypes or low-volume production.

1. Incredible repeatability and precision

Using CNC machining metal parts ensures a higher grade of accuracy and precision. The production runs in a consistent machining process and completely automated programming, allowing each part or prototype to be an exact copy of the first one. A completely consistent output and a faster and easier machining process are achieved.

2. Reduced production costs & errors

It has been a tendency to apply automated machining to the mechanical manufacturing industry with the development of science and technology. The completely automated process in a preprogrammed pattern is controlled by a computer or a robot, making it possible to save lots of effort and time, for example, reducing the workload and human involvement in production lines and thus lowering production costs.

3. High efficiency and flexibility

CNC machining has been commonly recognized as an ideal manufacturing process to make sure high quality in metal parts machining. The whole course of the manufacturing process is running on the base of automated machine positioning systems and adjustable fixtures, so it’s of greater flexibility to react to production schedules.

![]()

Fast turnaround time & quality

control system

![]()

A variety of surface finishes for CNC-machined metal parts

![]()

Tight tolerances. Within +/- 0.002 in. (0.05 mm) for metal parts

![]()

Comprehensive knowledge of CNC metal machining for years

Metal Alloys Available for CNC Machining

CNC machined metals are ideal for a series of parts ranging from prototypes to engineering models. And nearly all types of metal materials can be processed with modern machine tools of great rigidity and high power capacity. No matter for general-purpose materials that are highly machinable and thus ideal for testing designs at a low cost, like aluminum, or for some materials that are extremely durable and have incredible heat tolerance, like titanium, all of these metal materials can be machined.

If your project has a demand for parts with excellent properties like high resistance to impact and corrosion, and high heat deflection, you may consider CNC machined metal alloys as your primary choice. We have the capability to easily work with a variety of metals to meet your needs:

Aluminum Alloys

Aluminum 6061

Aluminum 5052

Aluminum 2024

Aluminum 6063

Aluminum 7050

Aluminum 7075

Aluminum MIC-6

Learn more about aluminum for CNC machining.

Copper Alloys

Copper 101

Copper C110

Learn more about copper for CNC machining.

Brass Alloys

Copper 260

Copper 360

Learn more about brass for CNC machining.

Stainless Steel Alloys

|

|

Learn more about stainless steel for CNC machining.

Steel Alloys

Steel 1018

Steel 1215

Steel 4130

Steel 4140

Steel 4140PH

Steel 4340

Steel A36

Learn more about steel for CNC machining.

Titanium Alloys

Titanium (Grade 1)

Titanium (Grade 1)

Titanium (Grade 2)

Titanium (Grade 5)

Learn more about titanium for CNC machining.

CNC Machining Processes Available for Metals

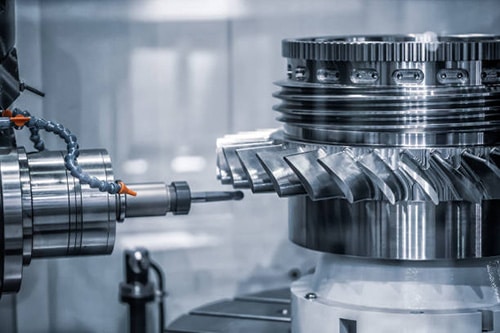

Milling

Milling uses a cutting tool that cuts through the metal stock in a rotatory movement. Features created in the milling processes include complex contours, flat surfaces, pockets, chamfers, and slots.

Turning

Instead of using a rotating cutting tool, the metal stock is the one that rotates while the tool approaches it in a linear motion. This process is perfect for creating cylindrical components.

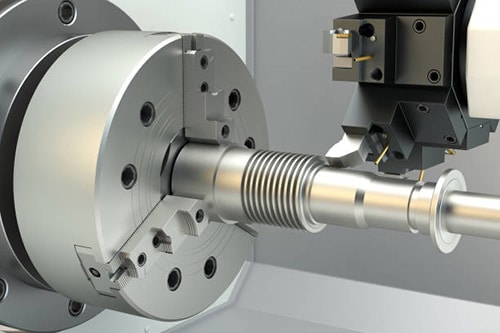

Drilling

It is specifically used to drill round holes in the metal stock. Its main difference from a handheld driller is that the movement is controlled by a lever to enlarge a drilled hole to a more precise diameter.

EDM

It involves a machining process that vaporizes particles from the surface using sparks from an electric current, instead of cutting through the metal materials. EDM can be adopted as an auxiliary machining process, especially in aluminum machining.

Wire EDM

It cuts the metal workpiece by the corrosion effect of the pulse discharge. A pulse current passes through the workpiece and a moving metal wire whose function is as the tool electrode.

Surface Finishes Available for Metals CNC Machining

After your metal parts are machined, Runsom can offer a wide range of post-processing and secondary operations adapting to your needs:

Anodizing

Powder coating

Bead blasted

Zinc plating

Gold plating

Silver plating

Nickel plating

Electroless nickel plating

Electropolishing

Titanium anodizing