Swiss CNC Machining

High-quality, cost-effective, and flexible Swiss CNC machining services

Precision custom CNC Swiss screw machined parts at low costs

Ideal for producing intricate cylindrical parts with high precision in large quantities

Precision Swiss CNC machining services are our specialty at Runsom Precision. We are proficient in Swiss-type machining with the use of the most advanced technologies and equipment, allowing us to produce high-quality precision-turned parts. We can offer you suitable cost-effective solutions no matter how complex your desired microcomponent is.

What Is Swiss CNC Machining?

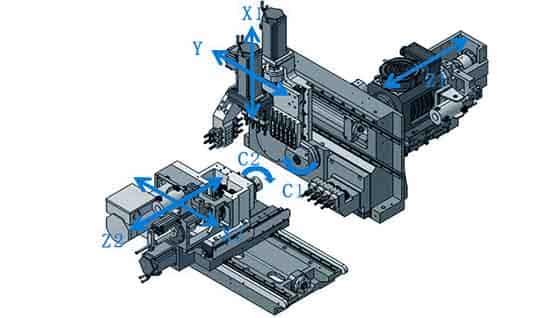

Swiss CNC machining is a specialized process to machine small, high precision turned parts. A Swiss CNC machine, also referred to as a Swiss automatic lathe, Swiss screw machine, or Swiss-type lathe, was originally designed for the Swiss watchmaking industry. Over the years, the Swiss-style turning machine has been refined to be widely used in various industries for high-volume, high-precision manufacturing – and for good reason.

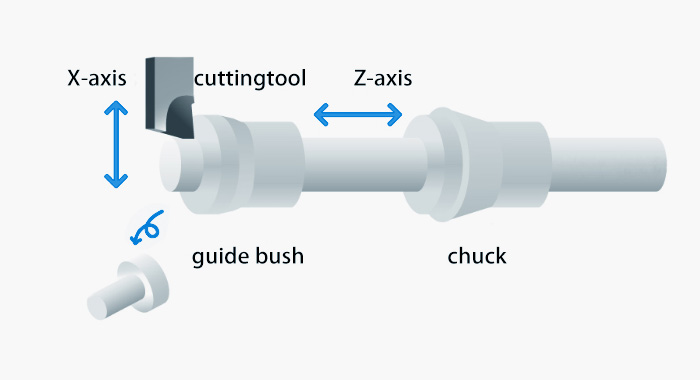

A Swiss-style lathe is a type of machine that cuts bar stock fed through a guide bushing while the tools keep stationary. The collet is recessed behind the guide bushing so that the bar stock held in it will have better support and will not directly be exposed to the lathe bed and the tooling, so the machine can process the material rapidly and tightly. Also, it plays a great role in decreasing tool deflection and vibration while increasing parts accuracy since the cutting tool can work nearer to the bushing.

How Does A Swiss-type Lathe Work?

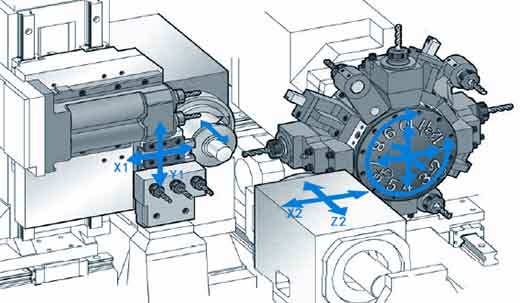

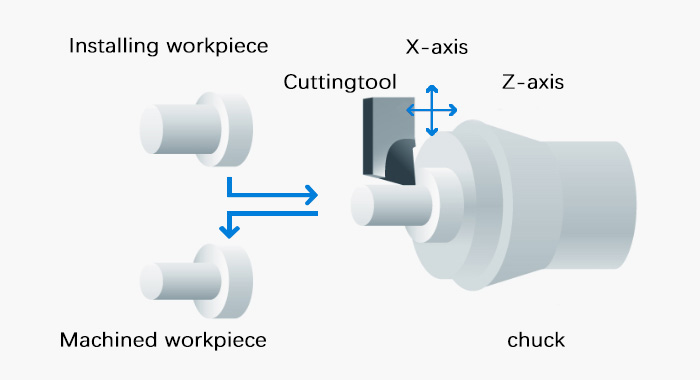

A conventional turning machine has a fixed headstock that holds the spinning workpiece when a cutting tool moves across to machine the outer diameter. However, in a Swiss CNC turning center, it employs a sliding headstock that feeds bar stock through a guide bushing in the Z-axis towards the stationary cutting tool.

In the turning operation, clamped onto the chuck or collet in the headstock, the bar stock is located radially and precisely. The headstock moves back and forth along the z-axis, taking the bar stock with it. The turning tools, carried on the gang slide, always engage the bar stock close to the bushing, usually within 1 to 3 mm, thus providing the greatest degree of support and decreasing vibration and tool deflection consequently. And continuous feeding is achieved by the movement of the spindle and the supply of the guide bush.

Swiss-type Turning

VS

Conventional CNC Turning

When it comes to fabricating precise components, there are inevitably distinct differences between CNC Swiss and standard CNC machinery. Each type of machine has its own characteristics and advantages for different machining tasks and applications.

Compared with a conventional lathe with fixed headstocks where the workpiece is clamped in a chuck or collet and extends to the enclosure of the machine as a cantilever or can be supported on the one end with a tailstock, the Swiss CNC turning machine has movable headstocks.

Swiss CNC Machining Service at Runsom Precision

Processing of shaft parts

The outer circle, drilling, boring, end face, turning, threading, cutting slot, cutting off, tapping, etc.

Industries we serve

Slender shaft parts or complex parts machined by Runsom Swiss CNC turning usually can be found in medical, aviation, military industry, automobiles, etc.

Material types & size range

Size range: 0.010" to 0.750" Diameter.

Materials types: Aluminum, Brass, Copper, Plastic, Stainless steel, Steel, etc.

The Key Benefits of Swiss CNC Machining

The good performance of Swiss CNC machining greatly benefits from the guide bushing and the geometry and mechanics that take place in the tool zone.

The chip-to-chip time from one tool to the next can be one second or less because the cutting tool operates near the guide bushing;

Capacity for 20 or more tools in the tool zone;

Shorter set-up times;

Often a single heavy cut helps to remove all the necessary material while preventing deflection;

Superior surface finish without the need for grinding;

Complex parts can be machined in a single cycle with more accuracy;

Multiple operations are performed on a part in a single machining cycle, making the part ready for shipment as soon as it is produced from the lathe;

Optimization of productivity-the right automatic bar feeder enables continuous, unattended, and even lights-out operation;

Tighter tolerances are realized by the sliding headstock & the guide bushing.

Why Choose Us for Swiss CNC Turning?

1. Productivity

High production work can be achieved by the automatic feeder designed to run lights-out and produce parts unattended. It can be expected to hold size with no variance while leaving a Swiss lathe running overnight without human involvement.

2. Cost saving

Compared with the high-cost production that comes with traditional turning, our Swiss CNC machining service provides you with a cost-saving and efficient solution for your demand.

3. Efficiency

Runsom Precision is equipped with Swiss CNC lathes that have a sub-spindle that allows live tooling work to be done on the back side of one part simultaneous to the front size of another part, essentially cutting in half the cycle time.

4. Quality

Runsom Swiss CNC lathes sit on an integrated casting bed, offering shock resistance and temperature stability. And our engineers have been experienced in Swiss turning operation for several years. Thus, your design will be realized from the idea to put into production with high accuracy under the support of our excellent machines and teams.