Whether you require an initial prototype or a complete set of components that are identical to each other, Runsom Precision offers exceptional 5-axis machining services to meet your goals within the specified time frame and budget.

For machined parts that are time-sensitive and have intricate geometric shapes, 5-axis CNC machines provide unmatched flexibility and efficiency. The skilled team at Runsom Precision can help turn your concepts to life, from rapid prototypes to end-use parts specifically designed for safety-critical applications. Our 5-axis milling abilities allow us to consistently manufacture exceptional parts within a short lead time.

What Is 5-Axis CNC Machining?

5-axis CNC machining is a manufacturing process that involves using computer-controlled technology to move a machine tool in five different directions. These directions are typically the X, Y, and Z axes for straight movements, and two additional axes for rotation. This type of machining is known for its versatility in handling parts of various sizes and shapes.

To perform 5-axis CNC machining, a machine tool needs a special computer system and software. These allow the operator to input the desired movements and tool paths for machining. The machine may also have additional features like a rotating table, which allows the workpiece to be turned in different directions.

Compared to conventional CNC machining techniques, 5-axis machining centers have several advantages. They eliminate the need for multiple setups, transferring and inspecting parts, and manual handling, which can lead to errors. With 5-axis CNC machining, a workpiece can be machined from different angles with high precision. This method is commonly used in manufacturing complex shapes, intricate parts, and components for industries like aerospace, automotive, medical, and electronics.

Advantages of 5-Axis CNC Machining

1. Short lead time

When using 3-axis machining, you need to set up the part multiple times and manually rotate it to machine different sides. But with a 5-axis machine, you don't have to go through the hassle of readjusting the position of the workpiece every time you change the setup for a complex-shaped part. This saves you time and reduces delays.

2. No need for complex fixtures

3-axis machining requires special fixtures to hold the part in the correct position. But with 5-axis machining, we can avoid using these complex fixtures. This is because the workpiece is held at one spot and rotated to create the desired shape, eliminating the need for additional fixtures.

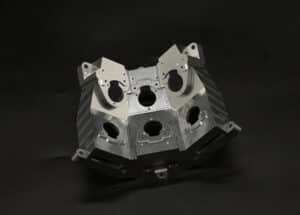

3. Intricate geometries

With 5-axis CNC machining, you can create parts with more complicated shapes and features. Regular CNC machines may struggle with complex geometric elements like curved lines and recessed areas, but 5-axis machines can handle them effortlessly.

4. Increased accuracy

Frequent setup changes can disrupt your work and cause accuracy issues. When you change the setup, you need to be extremely careful when placing the workpiece. Even a small mistake during placement can affect the precision of your parts. 5-axis machines can help solve this problem easily.

5. Faster material removal

In 5-axis machining, the cutting tool can directly touch the surface being cut. This means that more material can be removed with each pass of the tool, resulting in quicker machining speed. This increased efficiency helps reduce costs as well.

6. Superior surface finishes

In 3-axis machining, achieving the desired surface finish often requires making many small cuts, which takes a lot of time and adds to the cost. However, with 5-axis machines, which are better suited for complex shapes, you can achieve a much better surface finish more efficiently.

Advantages of 5 Axis Machining at Runsom Precision

Work with Runsom Precision, you'll have access to manufacturing experts who are here to help you every step of the way. This ensures that your project is completed with high quality, from the initial concept to the final outcome.

1. Fast turnarounds

Equipped with a complete set of 5-axis machines in-house, we're able to efficiently create prototypes and production parts for you in a matter of days. Your projects can be completed in a shorter timeframe, allowing for faster turnarounds.

2. Quality assurance

We have an on-site inspection system to support all precision machining processes. This allows us to effectively control the quality of our products and achieve very precise tolerances. We prioritize quality assurance throughout our operations.

3. Industry compatibility

We have experience working with a wide range of industries, including medical, electronics, and more. Whether it's manufacturing medical parts or high-tech electronic products, we have the expertise to cater to the needs of different industries.

4. Expertise and experience

With over a decade of experience in the machining industry, we have acquired comprehensive knowledge about different materials and their properties. This enables us to confidently handle complex parts, regardless of the material used. Our expertise ensures that your project is in capable hands.

5 Axis Machining Industries & Applications

Our 5-axis mills are capable of producing custom components that are used in a wide range of industries, including:

The Best 5-Axis CNC Milling Services With Ultra Precision

One of the primary advantages of 5-axis milling lies in its capacity to fabricate parts with intricate complexity using only a single tool setup. This reduces the necessity for human intervention, ensuring that components are machined with consistent accuracy and in significantly shorter turnarounds. With high flexibility and precision, 5 axis milling makes it possible to manufacture micro-components efficiently and accurately.

At Runsom Precision, we have honed our expertise in 5-axis CNC machining to create components considered to be nearly impossible to create. The ability to execute true 5-axis work requires highly remarkable programming and machining skills. The team of manufacturing engineers and machinists at Runsom Precision boasts over a decade of extensive experience in the CNC machining field. They exhibit excellent proficiency in operating 5-axis milling centers and delivering optimal outcomes.

Reach out to us online to get a free quote for our high-quality and affordable 5 axis machining services.

5-Axis CNC Machining FAQs

5-axis CNC machining involves using computer-controlled technology to move a machine tool along five different directions. These directions, labeled X, Y, Z, A, and B, allow for both linear and rotary motion. This flexibility enables the machine tool to access and process parts from various angles and orientations. This advanced technique enhances the manufacturing process by providing greater versatility and precision in creating intricate and complex components.

A 5-axis CNC machine uses special software to create a 3D model of the desired object. It then follows this model to cut or shape the material. The machine can move in different directions and angles thanks to its five axes of motion. This flexibility allows it to create complex and detailed objects with precision.

A 5-axis CNC machine boasts a multitude of benefits. It can move in five different directions, giving it the ability to machine complex shapes and contours with exceptional precision. It can also work on multiple sides of a workpiece at the same time, which saves time and increases productivity. By reducing the need for manual intervention, a 5-axis CNC machine improves the accuracy and consistency of the final product. These advantages help streamline the machining process and produce high-quality results.

In industries like aerospace, automotive, and medical, where precision and efficiency are crucial, 5-axis machining plays a significant role. It's used to produce intricate parts that require multiple angles to be machined in a single setup. With 5-axis machining, we can manufacture parts with complex geometries, including internal and external contours, holes, slots, and different planes and angles. It's also useful for crafting small and intricate components like dental implants and microelectromechanical systems (MEMS). Thanks to its versatility and accuracy, 5-axis machining is an essential process in various industries.

5-axis CNC machining is an advanced manufacturing technology known for its ability to produce extremely tight tolerances, even on complex and intricate parts. It’s one of the most accurate methods available, ensuring precision and quality in the production process.

5-axis machines expand upon the functionality of traditional 3-axis machines by incorporating additional movement options. They achieve this by tilting and rotating the table that holds the workpiece. These extra movements are known as the tilting table axis (A-axis) and the table rotation axis (B-axis).

In total, 5-axis machines operate along five different directions or axes: X, Y, Z, A, and B. These axes govern the movements of the cutting tools and the worktable. By using G-code instructions, the 5-axis CNC machine controls the precise motion of the cutting tools along the X, Y, and Z axes, while simultaneously directing the worktable along the A and B axes. These combined movements enable the creation of intricate and precise part designs as intended.

Here are the 5 axes:

- X - Left to right

- Y- Front to back

- Z-Top to bottom

- A-Titling table

- B-Table rotation

5-axis machining offers high efficiency and accuracy due to its ability to work on multiple faces of a part in a single operation. It is well-suited for parts with complex movements and intricate geometries that would otherwise require multiple setups. As part designers create increasingly complex parts, they often require machining on at least five different faces, making 5-axis machining a preferred solution in CNC manufacturing.

Compared to traditional 3-axis machining, 5-axis CNC machining allows the workpiece to travel along five axes instead of just three. While 3-axis machining is still versatile and useful for certain projects, 5-axis machining excels when dealing with parts that have more intricate designs.

However, if only one flat surface needs to be machined, 3-axis machines could be a more affordable option. In addition, 3-axis machines are easier to program, reducing labor costs.

In China, there are two main categories of 5-axis CNC machines. These machines have the ability to move along five directions, but their specific designs and structures may vary:

3+2 Axis CNC Machine

The 3+2 Axis CNC Machine is essentially a 3-axis machine with an additional capability to rotate the table. The tool functions similarly to a 3-axis machine, but the table can rotate along two additional axes. This allows machining at different angles without the need to manually change the setup or orientation of the parts.

However, it's important to note that the table and tool movement do not happen simultaneously. When one is moving along any axis, the other remains stationary.

Simultaneous 5 Axis CNC Machine

There is another type called "Simultaneous" or "Full 5 Axis CNC Machines". These machines can move the tool and table at the same time, which results in faster workflow and the ability to create more complex parts.

However, operating a simultaneous 5 Axis CNC machine requires skilled machinists with advanced programming knowledge and experience. This means that new machine shops may face challenges when working with these advanced machines.

The main difference between 5-axis and 3-axis machining is that 5-axis machining involves rotation of the A and B axes, enabling the production of more complex shapes with better surface finishes. Here are some distinct benefits 5-axis CNC machining offers:

- Shorter lead times: The advanced capabilities of 5-axis machines result in reduced production times, leading to shorter lead times for your projects.

- Improved accuracy and tool life: 5-axis machining offers a higher level of precision compared to 3-axis processes, which is particularly important when your finished products need to meet strict quality and performance requirements. By eliminating the need to move the workpiece between multiple workstations, the risk of errors is minimized.

- Use of shorter cutting tools: Creating high-quality 5-axis machined parts using shorter cutters helps reduce vibration that often occurs when using a 3-axis process to machine deep cavities. Shorter cutting tools also allow for higher cutting speeds without exerting excessive pressure on the tool.

Both 3+2 Axis CNC machining and full 5 Axis CNC machining are technically considered as 5-axis machining because they have five axes of freedom. However, in terms of capabilities, full 5 Axis CNC machining is superior to 3+2 Axis CNC machining.

The main difference between these two types of machines lies in how they function. A 3+2 Axis CNC machine is essentially an extension of a 3-axis machine. The key difference is the addition of two extra rotational axes for the table.

With a 3+2 Axis CNC machine, instead of manually changing the orientation of the parts, the workpiece can simply be rotated. However, a disadvantage of this approach is that the table and tools do not move simultaneously. While the table changes the orientation of the workpiece, the tool remains fixed in the three main axes.

As a result, 3+2 Axis CNC machines have certain limitations, and achieving certain complex geometric features may be challenging. However, they provide a more affordable solution compared to simultaneous/full 5 Axis CNC machining.

In contrast, full 5 Axis machines are more versatile but relatively more expensive than 3+2 Axis machines. These machines can simultaneously control the movement of both the table and tools. This allows for easier handling of more complex geometries.

Full 5 Axis CNC machining is especially suitable for creating complex arc shapes and undercuts in parts. It can easily reach recessed areas of the part. The simultaneous movement also helps reduce overall machining time.

To learn more about 3+2 axis CNC machine and simultaneous 5 axis CNC machine, and know their difference, you can refer to this post: The Difference between Simultaneous 5-Axis and 3+2 Axis Machining

The basic principle of all CNC machining processes is similar, but there are significant differences between 3, 4, and 5-axis CNC machining. These differences make each type more suitable for specific tasks.

3-axis machining is the traditional CNC machine tool that operates on the X, Y, and Z axes. In this process, the workpiece remains stationary, and the cutting tool moves according to the design to cut the material. However, 3-axis machining has limitations as it cannot rotate or spin like 4 or 5-axis machines. To machine details from different angles, the workpiece needs to be manually adjusted.

On the other hand, a 4-axis machine tool has an additional axis called the A-axis. Like a 3-axis machine, it has the X, Y, and Z axes, but it can also rotate the workpiece along the A-axis. This allows machining from different angles without changing the setup.

A 5-axis machine is the most advanced among CNC machining equipment. It has two additional rotational axes (usually denoted by A and B) in addition to the X, Y, and Z axes of a traditional 3-axis machine.

5-axis machines can handle more complex designs and shapes compared to 3 and 4-axis machines. They also make it easier to perform undercut designs in a single setup, which is more challenging for 3 and 4-axis machines.

Overall, 5-axis machining provides better quality and surface finishing for parts. Due to its single setup functionality, it is faster than 3 and 4-axis CNC machining.

You can learn more about the difference between 3-, 4-, and 5-Axis CNC Machining from this blog: Differences between 3-, 4-, and 5-Axis CNC Machining

The accuracy of 5 Axis CNC machined parts can be evaluated using a Coordinate Measuring Machine (CMM). This device detects specific points on a part using a probe, enabling measurement of its geometric aspects.

CMMs come in different types, categorized based on the type of probe used for measurement. Common probes include optical, mechanical, laser, and others. Each probe has its own level of accuracy.

CMMs can be operated manually or by hand. They typically allow movement along the three main axes: X, Y, and Z. Some CMM machines also support angular movement, enabling measurement of more complex details.

At Runsom Precision, we utilize an advanced CMM that is equipped with an automatic scanning feature that can perform repeated measurements to ensure optimal precision in our CNC machined parts.

We are a supplier that offers the most competitive and advanced selection of 5-axis machine configurations in this field, ensuring you a more economical and efficient solution with faster production turnaround and lead time with outstanding quality. Perhaps not only can we offer you the 5-axis machining expertise, but also help you to be acquainted with the very complex nature of your design requirement.