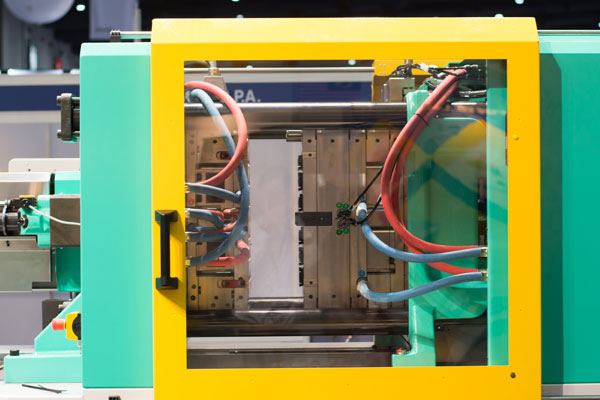

Runsom Precision is specialized in producing high-quality plastic injection molding parts and mold tools, we provide CNC machining and finishes services to make injection molding tools from various metal materials. Our capacity includes 50 to 100000 injection molded parts in a wide type of plastic materials. Compared with CNC machining and 3D printing, our injection molding service can provide the most variety of materials, colors, and configurations. In addition, we can also satisfy your customized cosmetics, polishes, and surface textures for aesthetic needs or technical requirements.

We guarantee your injection molding tools and parts exceed your expectations with advanced material verification and quality process management. We provide multiple options of injection molds for your exceptional production cycles and warranty, including “in-house” and “export” injection molds as your indeed requirement.

Why not upload your production design file for a competitive injection molding quote now?

How Does Plastic Injection Molding Work

To put it simply, the injection molding process can be simplified into four steps: melting the material, injecting it into the mold, cooling the material (or allowing it to cool) until it hardens, and then ejecting the final part from the mold.

Melt

Inject

Cool

Eject

Although this process seems to be easy and simple, there are many elements and factors needing taking into account to make sure every single piece of plastic component is fabricated precisely. To have an overall understanding of the process and crucial parameters, it’s necessary to know the elaboration of every stage below.

It’s essential to determine exact thermoplastics and create right molds before the actual process starts because these will affect the forming of final products directly. Thus, manufacturers have to think over the interaction between the thermoplastic and mold, due to the factor that not all types of plastics can be machined for mold designs.

Injection molding starts with feeding raw pellets of the chosen thermoplastics into a hopper at the top of the machine. Then these pellets are gradually moved from the hopper to a barrel with the turning of the screw. As a result, the thermoplastics are molten with the rotation of the screw and the heat from the barrel continuously.

Therefore, it’s of great importance to rightly control and maintain the proper temperatures in this part of the process to guarantee the efficient injection of plastics and accuracy of final parts.

The gate (controlling the injection of plastic) closes and the screw moves backward when the melted plastic reaches the end of the barrel, which makes preparation for injection by setting the amount of plastic and gathering pressure in the screw. At the same time, the two parts of the mold are closed and held under high pressure, which is the so-called clamp pressure.

The injection pressure and clamp pressure must be balanced to ensure that the parts are exactly formed and that no plastic leaks out of the tool during this process. Once the tool and screw reach the appropriate pressure, the gate will open, the screw will move forward, and the molten plastic will be injected into the mold.

The holding time refers to a set period for the plastic held under pressure after being injected into the mold. The length of this phase is determined by the type of thermoplastic and complexity of the part ranging from milliseconds to minutes. Also, it’s one of the key assurance for the plastic packing out the tool correctly and being formed rightly.

Likewise, the cooling time can also vary from a few seconds to some minutes, which is occurred after the holding period when the screw draws back, releasing pressure and allowing the part to cool in the mold. It will affect the component shaping before it is ejected and finished on the production line.

After being cooled and solidified, the molded part will be ejected by pins or plates that help remove the part from the mold without breaking it. In some cases, some secondary processing may be required, such as dying or removing excess plastic (known as spurs), and polishing, before the molded part is ready for package and delivery.

Advantages of Plastic Injection Molding

1. Efficiency

Plastic injection molding is a highly efficient process to quickly deal with large-volume orders.

3. Fineness

The molten material can reach every crevice of the mold under high pressure before solidifying, which enables engineers to incorporate sophisticated elements and complex geometric structures into their designs.

5. Volume production

Injection molding can be ideal for low-volume production of 250 units to high-volume production of over 1,000,000 units. Moreover, employing steel molds in injection molding can speed up the mass volume production of millions of identical parts.

2. High durability

The tensile strength of the molded parts may be enhanced by adding fillers into the liquid resin.

4. Cost-saving

This technique realizes efficient and productive production, making it possible to produce per part at a low cost. The cost can also be further lowered by selecting materials for injection mold tools that are cost-effective and readily available, such as aluminum.

6. Smooth finishes

The molded parts are ready for package and delivery with a neat finish that is unnecessary to be further processed when it’s removed from the mold.

Injection Molding Options for Plastic Part Production

Plastic Injection Molding

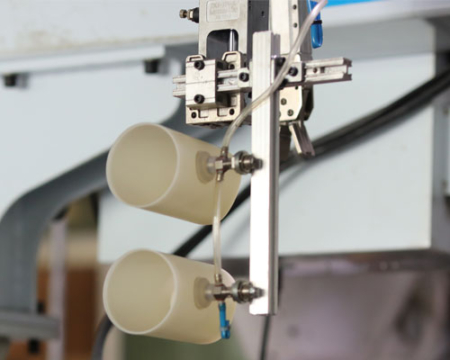

Runsom Precision has more than 10 years of experience in plastic injection molding manufacturing, our engineers can convert your 3D design files into high-quality molds at top speed. Our manufacturing services include: tools dies and molds from design to production, aluminum and steel tooling, overmolding, and insert molding, and plastic blow molds. We use various kinds of steel or aluminum to make molds due to their durability and excellent injection abilities. The structure of a mold is decided by the part design.

Runsom Precision has more than 10 years of experience in plastic injection molding manufacturing, our engineers can convert your 3D design files into high-quality molds at top speed. Our manufacturing services include: tools dies and molds from design to production, aluminum and steel tooling, overmolding, and insert molding, and plastic blow molds. We use various kinds of steel or aluminum to make molds due to their durability and excellent injection abilities. The structure of a mold is decided by the part design.

We can provide plastic injection molding for low volume and batch production. Our injection molding capability ranges from 50 to 1000 tons of clamping force allowing us to manufacture any type of plastic part, such as micro parts, 0.0003m thin-walled parts, and various large parts.

Insert Molding

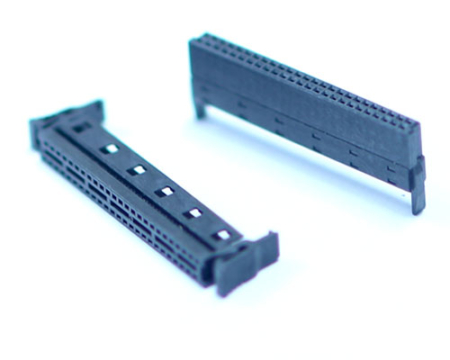

Rusnom can provide insert molding services in your design, metal, ceramic, or plastic pieces will be inserted into molten thermoplastic to form robust and functional parts as intended requirements. Our CNC machining service can produce precision customized metal, ceramic and plastic inserts to integrate molded parts. Insert molding is a cost-effective way than installing after molding.

Rusnom can provide insert molding services in your design, metal, ceramic, or plastic pieces will be inserted into molten thermoplastic to form robust and functional parts as intended requirements. Our CNC machining service can produce precision customized metal, ceramic and plastic inserts to integrate molded parts. Insert molding is a cost-effective way than installing after molding.

In addition, by integrating insert parts in molding, insert molding parts are more robust compared to staking pieces in post-molding. It should notice that insert pieces must withstand high temperature and pressure in the molding process.

Overmolding

Our over molding service allows multi-material injection molding in your molded parts production. Through overmolding, the thermoplastic elastomer can be molded onto rigid plastic. Overmolding is useful for producing multi-material parts with unique properties. Basically, a previous injection molded part (substrate) will be formed by a new layer of different material (overmold).

Our over molding service allows multi-material injection molding in your molded parts production. Through overmolding, the thermoplastic elastomer can be molded onto rigid plastic. Overmolding is useful for producing multi-material parts with unique properties. Basically, a previous injection molded part (substrate) will be formed by a new layer of different material (overmold).

Overmolding is not as straightforward as single-material injection molding. We should consider the chemical and thermal compatibility of the two materials. Substrate material must have a higher melt temperature than overmolding material, in order to avoid being molten and deformed in the injection process of overmolding material.

Almost all thermoplastic can be used for plastic injection molding production. Runsom Precision provides flexible and rigid plastic varieties. Custom resin matching available is as follows:

Engineering plastics offer a range of sought-after properties, including good impact strength, rigidity, thermal resistance, chemical resistance, dimensionality, and color stability. The combination of strength, ductility, and heat resistance makes rigid plastics suitable for a range of industrial injection molding applications.

Subtypes:

| ABS | PEI | Nylon 6/6 |

| Acetal POM | PLA | PBT |

| Acrylic | Polycarbonate | PC-PBT |

| HDPE | Polypropylene | PEEK |

| PPS | PVC |

Surface Finishes for Plastic Injection Molding

Pad printing always can add images like logos or company names to the final parts.

No matter customer-supplied parts samples or Pantone color numbers, the painting colors made by Runsom will 100% match your requirement.

Laser finishing can be applied to mold or final parts for company or product information.

Heating staking can be used for threaded insert with your complete design chart.

We apply industry-standard textures to the molding manufacturing process, you can get a mold-tech finish equivalent.

Runsom is also proficient in assembling and labeling injection molded components. If you have demands like these, reaching out to Runsom is the way to go.

Advantages of Plastic Injection Molding at Runsom Precision

High precision

Molds manufactured by our advanced CNC and EDM machines for plastic injection molding are highly precise and accurate to produce large quantities of production parts with small and intricate details.

No minimum order quantities

Whether you need to quickly test out the market with low-volume parts or want to create mass production molding of million units, we can all accept and help you to realize your design and boom your business.

Dust-free facilities

The production environment of injection molding is dust and temperature controlled to further guarantee the performance of molding.

Various secondary operations

We can offer you one-stop services from design and prototyping to final production and after service so as to create more flexibility and choices for our customers.

Sufficient materials options

There are numerous raw materials for both mold making and plastic injection molding. And you can always select the cost-effective and affordable materials with good properties to make molds.

Overall Technical Support

Our technical team will provide professional support for your needs as long as you have any questions or want to consult our experts in CNC machining and plastic injection molding.

Get a custom injection molding quote online and a design analysis today.

Applications of Plastic Injection Molding

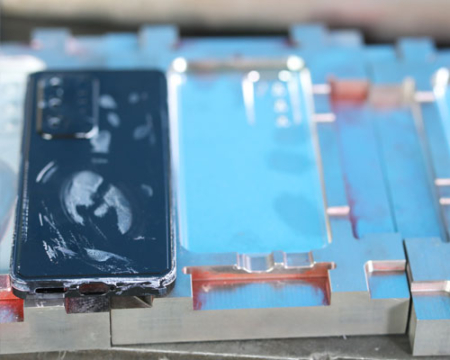

Injection molding is widely used to produce various plastic parts for various sizes, complex shapes, and different use of applications. And it is also used in medical equipment and mechanical parts.

Plastic cases as the most common product are used widely in household appliances, consumer electronics, power tools, and car dashboards. Others like computer components, containers, bottle caps, car interiors, lenses, brackets, fasteners, top and bottom covers, and toys.

- Production Parts

- Bridge Tooling

- Rapid Prototyping

- Pilot Runs

- Functional Testing

Injection Molding Design Tips

Professional design guidelines provided by the engineering team at Runsom Precision are as follows:

Smallest and Constant wall thickness will be considered to avoid warping and sinking.

Smooth chamfer or fillet can be used to make transition for 3 times wall thickness difference.

Add a large radius fillet to internal and external edges.

Add draft to all vertical walls design, avoid drag and make parts easy to be ejected.

Injection Molding FAQs

Plastic injection molding is the process of melting plastic pellets (thermosetting/ thermoplastic polymers). And once these pellets have enough ductility, they will be injected into a mold cavity under pressure that is filled and solidified to produce the final product.

The molding machine heats the plastic until it is liquid. The nozzle of the injection molding machine then injects the molten plastic into the mold (injection pressure). The cavity of the mold is now filled with plastic liquid. This will then cool down to form a solid product.

Six types of plastic moulding are universally acknowledged for effective results. They are:

- compression moulding

- blow moulding

- extrusion moulding

- injection moulding

- rotational moulding

- blow moulding

Injection molding is popular among a multitude of industries including consumer goods, energy, electronics, aerospace, medical devices, robotics, toys, automotive, and more.

Injection molding can use almost any type of plastic, and raw plastics can also be combined. This incredible versatility makes this technique so perfect and suitable for some of the most demanding industries in the world. You can view a selection of available materials and finishes for our injection molding services on this page.

The cost of plastic injection molding depends on order size, part complexity, and other factors. The initial cost of injection molding may be high, but it is cheaper in the long run, so it is most suitable for mass production.

Request instant pricing on your plastic injection molding project now!

This thermoplastic injection molding material can typically be found in the food storage and packaging industry because it can effectively prevent food products from mixing with chemicals. Polypropylene (PP) can be washed in hot water without deterioration and it is highly resistant to chemicals and moisture.

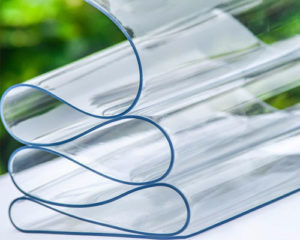

Flexible plastics are also broadly used in injection molding for applications that require elasticity. The fast curing materials are used in the manufacturing, military, and art sectors, to name but a few.

Flexible plastics are also broadly used in injection molding for applications that require elasticity. The fast curing materials are used in the manufacturing, military, and art sectors, to name but a few. Rubber plastics are well suited for injection molding because they can easily be brought to the molten state and poured into molds. When solidified, they do not require any release agents to be removed from the molds. Rubber plastics demonstrate good flexibility and great resistance to high temperatures for post-cure processes, and cost-efficiency.

Rubber plastics are well suited for injection molding because they can easily be brought to the molten state and poured into molds. When solidified, they do not require any release agents to be removed from the molds. Rubber plastics demonstrate good flexibility and great resistance to high temperatures for post-cure processes, and cost-efficiency.