CNC Machining Service for Communication Industry

Accurately crafted telecommunications parts tailored to specific requirements

Rapid delivery within several days at a competitive price

High-quality communication parts with tight tolerance

Precision CNC Machining Serves Communication Industry

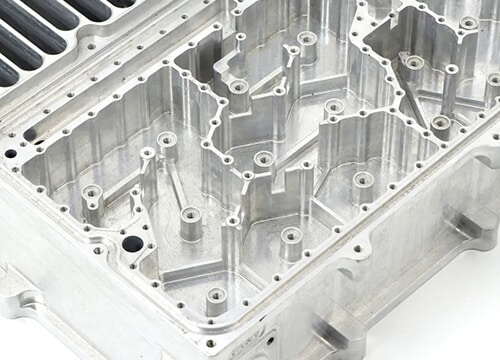

CNC machining proves to be an efficient method for producing accurately manufactured components for telecommunications equipment. Computer technology enables intricate details to be designed and produced with precision. With the high accuracy achieved through computer-controlled production, CNC milling is highly accessible to innovative design with precision products. CNC machining is a versatile technique for manufacturing parts from high-strength materials like stainless steel, steel, brass, and aluminum. Moreover, due to its high production efficiency, large-volume orders can be completed quickly.

Machinists at Runsom Precision are proficient in utilizing CNC machining technologies to make products, even for the most intricate components. With their extensive experience and the help of equipment facilities, they are allowed to produce high-quality precision machined parts and products for a diverse range of applications, including in the communications industry.

Why Use CNC Machining for the Communication Industry

The significance of telecommunication technologies is increasingly growing in our daily life, which will continue to expand as the world is getting more interconnected. Hence, industry experts consistently endeavor to enhance the reliability and performance of individual parts and overall systems.

CNC machining plays an essential role in the communication industry, where they procure accurately crafted components that further support this constantly changing field. The performance and reliability of communication equipment depend significantly on the quality of parts used in its design. Using inferior-quality components may lead to equipment malfunction causing poor video transmission, interrupted calls, and satellite broadcast blackouts.

Horizontal & Vertical Milling for Communication Parts

Horizontal milling centers that are equipped with a horizontal spindle orientation are ideal for pocketing and facing projects due to their enhanced efficiency and speed. Their great strength lies in their ability to rapidly remove substantial amounts of material.

Vertical milling centers that feature a vertical spindle orientation have it positioned straight up and down. They are user-friendly and don't require complex fixtures or setups, making them a simple yet effective option for short-run projects.

Runsom Precision provides various CNC machining options for the communication industry based on a project's unique requirements such as part shape and production volume. By utilizing vertical and horizontal milling centers, we're able to cater to the diverse needs of both the communications and telecommunications industries. Our state-of-the-art CNC machine shop is well-equipped with the latest machining centers that can handle typical vertical and horizontal milling and turning tasks, along with creating innovative solutions to suit any application within the communications sector, providing exceptional flexibility and capability.

Benefits of Machined Parts for the Communication

Precision CNC machining confers numerous benefits for the communication industry to manufacture parts and products, such as:

Precision machining helps telecommunication manufacturers convert diverse designs into tangible products with increased design flexibility. The components and products can be customized in such a way that they can handle highly specialized or unique requirements like variable weather conditions, no-lag necessities, and high-volume data capacities. Hence, precision machining allows manufacturers to offer more innovative solutions.

It's an extremely efficient and cost-effective approach to creating accurately built components and products that function in various communication devices, including switches, antennas, RF connectors, etc. CNC machining is useful in minimizing costs related to product development by reducing waste production correlated to traditional manual machining.

Precision machining ensures unmatched accuracy and consistency in product designs, coupled with precise quality control for the communication parts. The relatively tighter tolerances with reduced variation from piece to piece and batch to batch are crucial in limiting poor video transmission quality, equipment failure, call interruption, or other issues caused by inferior-quality parts.

High-strength materials like aluminum, brass, steel, and stainless steel are accessible in the CNC machining process which expands the material availability of the components. Manufacturers are free from concerns while using these materials in their designs.

CNC machining proves to be a highly efficient process that reduces setup times and facilitates faster turnaround times and productivity while maintaining product quality. Its scalability makes it ideal for any application size or project, especially for creating parts used in the communications industry.

Applications of Precision Machined Parts for the Communication Industry

Communication systems entail a complex component subsystem that coordinates to receive, transmit, and process information between concerned parties. To ensure proper functioning, many of these components require designing and building with high accuracy and precision, thereby relying on precision machining processes. The typical parts employed in communication equipment are as follows:

Companies also prefer precision machining techniques to create fully functional telecommunication devices and systems, including:

Work with Runsom Precision for Your CNC Machined Communication Parts

For your next project within the communications industry, Runsom Precision is the ideal partner to turn to. We have been providing precision manufacturing solutions to some of the leading players in the telecommunication field and receive good feedback. You can rest assured that we have the capability to meet all of your requirements.

If you are interested in discovering more about our capabilities in precision machining and how we can help you, reach out to us today. To have a consultation with a member of our team regarding your project's needs, simply request an instant quote from us.