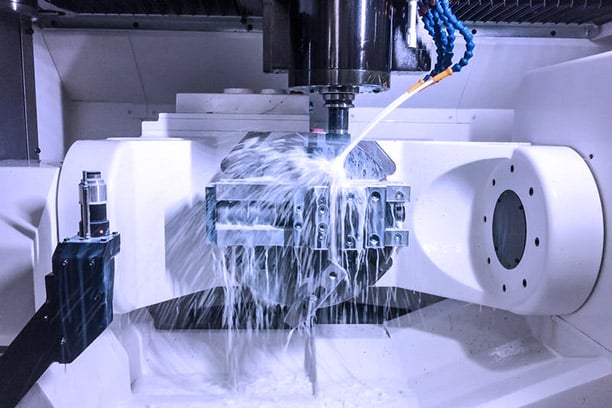

The use of a milling machine enables the cutting and production of specific parts or components for a project, without the need to add materials as in additive manufacturing. This is achieved by the CNC milling machine through the process of subtractive manufacturing, which cuts away excess materials to attain the desired look or function.

To complete a project, there are various types of mills available, including vertical mills and horizontal mills. Both vertical and horizontal mills can work for different industries, even though they differ. Understanding which milling machine to use for a project or business can reduce the risk of costly mistakes and provide the best tools to achieve desired results.

This article provides detailed information on the differences between horizontal and vertical milling machines, their advantages and disadvantages, and how to choose the best one for a particular project.

Introduction to A Vertical Milling Machine

The common setup for vertical milling machines features the cutting tool being oriented vertically and cutting against a stationary workpiece based on the design requirements. Two types of vertical milling machines are commonly used in the industry: knee mills (also known as turret milling machines) and bed mills, each with its own unique advantages and functions.

Knee Mills

Knee mills are a popular choice in machine shops and typically feature a fixed spindle. These mills have a vertical knee movement on the Z-axis, while the table moves along the longitudinal X-axis and Y-axis.

Nowadays, many CNC mills are knee mills, which can either be stand-alone or benchtop models with a variable-speed design allowing for a multitude of machining uses.

Bed Mills

A bed mill differs from knee mills in that their table does not move up and down along the Z-axis. Instead, the spindle provides vertical movement. Unlike the knee mill, which only moves the quill and not the motor, the whole head and motor of the bed mill move up and down on the Z-axis. But both knee mills and bed mills utilize movement along the X-axis and Y-axis for the work table. Bed mills work well for large and heavy workpieces.

Learn more about our CNC Vertical Machining Services

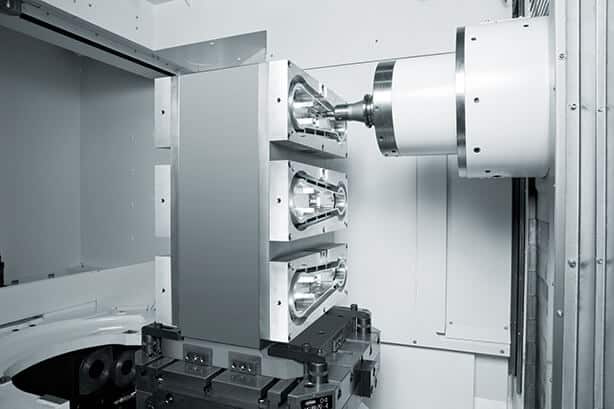

Introduction to A Horizontal Milling Machine

The horizontal milling machine has a spindle that rotates in a horizontal position. Its cutting tools are often shorter and thicker compared to the long, thin end mills used in vertical counterparts.

Although CNC vertical knee mills are more versatile, horizontal mills can handle heavier and deeper cuts. These machines typically have stronger motors to process larger beds and heavy workpieces.

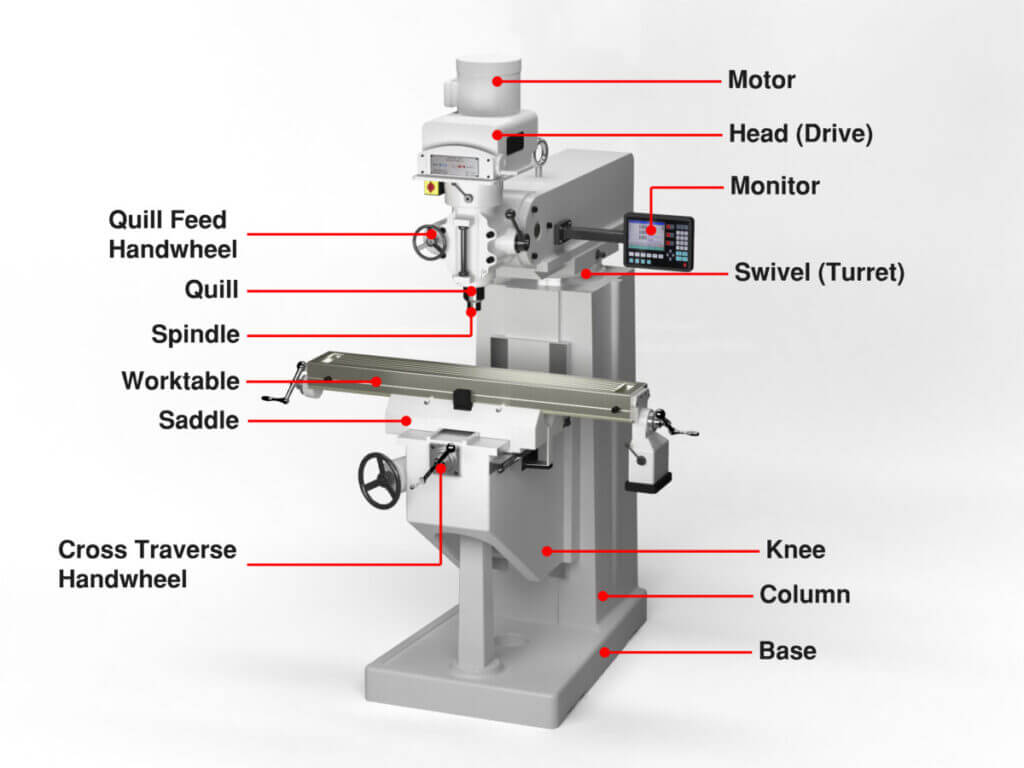

The main structure of a horizontal milling machine is composed of :

- Base: The base supports the machine and is responsible for absorbing and dampening any vibration that may occur during operation.

- Column: The column houses the spindle and is mounted vertically on the base. It provides support and rigidity to the machine.

- Knee: The knee is a vertically adjustable component that is mounted on the column. It can be moved up or down using hand cranks, which enables the operator to adjust the height of the worktable for different machining operations.

- Saddle: The saddle is mounted on top of the knee and can be moved in either direction on the ways of the machine. It holds the worktable and enables it to move from side to side.

- Worktable: The worktable is mounted on the saddle and can move in different directions depending on the machining operation. It has T-slots to hold the workpiece securely during machining.

- Spindle: The spindle is mounted horizontally on the column and rotates to drive the cutting tool. It is driven by a motor that is located either in the column or in the base.

- Arbor: The arbor is a long, cylindrical component that is inserted into the spindle and holds the cutting tool. It can be adjusted to ensure accurate alignment of the cutting tool with the workpiece.

- Overhanging arm: Aligning and supporting the arbor support.

- Arbor support or bracket: It’s attached to the overhanging arm, supporting the end of the arbor on the opposite side of the spindle.

Learn more about our Large Part CNC Machining capability

Horizontal vs. Vertical Mills: 11 Key Differences Explained

In this section, we’ll discuss the fundamental differences between horizontal milling machines and vertical milling machines from eleven perspectives.

1. The Orientation of the Spindle

Horizontal milling machines have a horizontal spindle that operates parallel to the ground and is supported by a horizontal arbor. The cutting tool is mounted on the arbor and rotates along a horizontal axis.

On a vertical mill, a vertical spindle that is oriented perpendicular to the ground and is supported by a vertical column. This setup is similar to a bench drilling machine: the cutting tool is mounted on the spindle and rotates along a vertical axis.

The orientation of the spindle affects the types of cuts that can be made with each machine. Horizontal mills are better suited for heavy-duty cutting operations and can handle larger bulkier materials. They are commonly used in industrial applications such as manufacturing large metal parts like engine blocks. Vertical mills, on the other hand, are better suited for precision cutting operations and are commonly used in small to medium-sized manufacturing operations. They are ideal for producing parts with complex geometries and can be used for both roughing and finishing operations.

2. Tool Geometry

Another difference between the two types of milling machines from a tool geometry perspective is the way in which the cutting tool is oriented.

Horizontal milling machines use short and thick tools that can remove a considerable amount of material from the workpiece. In a vertical milling machine, long and thin tools are used for different precision and cutting techniques.

The orientation of the cutting tool affects the type of cutting operations that can be performed, as well as the types of workpieces that can be machined effectively. The nature and accuracy of the cuts each machine can make depend on the shape and type of cutting tool used. Generally, vertical milling machines are more versatile and can be used for a wider range of cutting operations, including drilling, slotting, and surfacing, while horizontal mills are better suited for heavier, larger workpieces.

Learn more about our CNC Drilling Services

3. Cost of Each Machine

Horizontal milling machines tend to be more expensive than vertical milling machines. This is because they are typically larger and more complex machines, with additional components required to move the workpiece in multiple directions. They also require more space and may have higher technical requirements, which can add to the overall cost.

Among small shops, vertical milling machines are more commonly selected than horizontal counterparts because they have a lower initial cost and lower expenses for operation and maintenance. This makes them a more popular choice. In addition, since vertical machines are more familiar to machinists, they are easier to operate and less expensive than horizontal ones.

However, the cost can depend on the specific features and capabilities of the machine in question. Note that the cost of a mill can vary widely depending on factors such as brand, model, condition, and accessories included.

4. Cutting Specifications and Output

The cutting specifications are influenced by the geometry of the cutting tool. Horizontal tools are sturdier due to their shorter, thicker design, and can create deeper cuts while withstanding resistance, allowing for cutting multiple grooves or slots and performing heavy-duty cutting operations on large and heavy metal pieces.

Vertical tooling is perfect for cutting slots, drilling holes, and performing most general operations. They are typically better suited for performing smaller cutting operations. The vertical spindle allows for the use of high-speed cutting tools, which can enable faster and more efficient cutting.

5. Versatility

Vertical milling machines are extremely versatile and are preferred by machinists because they can be used as boring mills as well as drill presses. Unlike horizontal mills, they can easily transform into drill presses. In addition to being able to face and slot, these machines are particularly good at tasks such as prototyping, custom work, and even engraving.

6. Extent of Customizability

Horizontal milling machines tend to offer more extensive customizability options than vertical ones. This is because the design of a horizontal milling machine allows for a greater range of cutting movements and positioning options, which in turn, allows for more specialized machining operations. Furthermore, most horizontal milling machines have more tooling and workholding options available, which can be tailored for specific applications.

7. Material Removal Rate

From a material removal rate perspective, horizontal milling machines are more efficient than vertical ones due to their superior stability and the capacity to make deeper cuts. Although vertical mills are commonly used for delicate or intricate cuts, where precision is essential and cuts are shallow, their limited cutting capability results in a lower removal rate.

8. Chip Evacuation

While using a vertical mill for machining, the metal chips that are generated usually stick to the surface of the workpiece. This causes them to melt and create defects, which may require post-processing operations. In contrast, when using a horizontal cutter, the chips are ejected away from the worktable and towards the floor, resulting in a more refined machined surface.

9. Number of Sides for Machining

The use of horizontal machinery enables a versatile approach to workpieces with the ability to access them from various directions and angles. However, vertical tools only operate on one surface.

Additionally, the horizontal setup is better tailored for intricate and adaptable tasks. It also allows for the incorporation of extra components and functionalities, which are not available in vertical milling machines. As a result, vertical mills have a restricted range of operations.

10. Overarm and Arbor Support

The presence of an overarm or arbor support is also a distinguishing feature between the two types of machines. A horizontal milling machine features two distinct components – an overarm and arbor support. The overarm constitutes a level beam at the apex of the column. Depending upon the specific machining requirement, either a cutting tool or an arbor may be held in a horizontal mill. If an arbor is utilized for a specific milling task, arbor support is necessary to align it and provide support. These support structures are typically fixed to the overarm and are unique to the horizontal mill.

11. Operating Difficulty

Generally, horizontal milling machines are considered more challenging to operate than vertical milling machines due to the following reasons:

- Setup: Horizontal mills require more tooling and fixtures, which can take longer to set up.

- Cutting speed: Higher cutting speed in the horizontal machining process means that operators need to pay close attention to the milling process and make sure that the machine is running smoothly and safely.

- Material handling: Compared to a vertical milling machine, the workpiece located on a horizontal spindle is more difficult to access and manipulate.

Pros and Cons

The table below elaborates on both pros and cons of a vertical and horizontal milling setup.

| CNC Vertical Mills | CNC Horizontal Mills | |

| Advantages | Versatility: The vertical setup is well-liked in the industry due to its lower maintenance costs, and it’s not difficult to find specialists who can operate them. Affordability: Vertical machines are cheaper and readily available, which makes them a viable investment for small businesses that want to begin the fabrication process. Simplicity: Vertical mills are simpler to operate compared to their horizontal counterparts due to their greater visibility to users and lower programming requirements. Low-volume production: Vertical mills are preferred for low-volume production since they’re relatively simple and cost less. Thus, programming and planning activities take less time. | Better chip evacuation: Remove metal chips more effectively which results in a better finished material. Vertical machines throw the chips onto the surface, which can cause small flaws that may require further work. Durability: Provide more stability during deep cutting operations because their cutting tool is thicker and shorter, which reduces vibrations and provides steadiness. Large capacity: Allow for various angles and add-ons that are not possible with a vertical milling setup. High output rate: Offer higher productivity because they have a higher material removal rate, better chip evacuation, and can make deeper cuts in one go which results in less time needed to complete a task. |

| Disadvantages | Low output rate: Vertical mills have lower production output since they remove material at a slower pace and aren’t suitable for large parts. Shallow cutting depth: Vertical cutting tools are unstable, which limits their capabilities in dealing with more complex parts and grooves that require the greater depth. | High costs: Expensive, both initially and for maintenance. Challenging: Highly skilled operators for horizontal milling machines can be difficult to find since they are not as widely available as vertical ones, thus few people have experience working with them. |

| Applications | 1. Manufacturing automotive parts such as shafts, gears, pins, etc. 2. Producing parts for the transportation industry, such as automotive accessories, motorcycle parts, engine components, etc. 3. Prototyping, custom work, or engraving. 4. Face, slot, drill, and bore: production of machinery and tooling used in manufacturing processes. 5. Completing metalworking projects, even working as a router. | 1. Gear cutting: The horizontal milling machine can be used for cutting gears and splines, which are used in industrial machinery. 2. Surface machining: A horizontal milling machine can be used to create flat surfaces on a piece of metal or other material. 3. Slot milling: The machine can also be used for making slots in workpieces. 4. Profiling: The machine can be used for profiling and shaping complex surfaces. 5. Boring holes: The horizontal milling machine can be used to bore holes in materials. 6. Cutting keyways: The machine can also be used for cutting keyways in shafts and other components. |

How to Choose between Horizontal and Vertical Milling?

The choice between vertical and horizontal milling machines depends on a few factors such as the shape and size of used materials, time required, and budget. Each type of machine is suitable for various tasks, but you need to choose the right one based on your requirements.

1. Size

Vertical milling machines are great for smaller workpieces as their cylindrical and small design allows you to target specific areas with precision. However, they are not ideal for deep operations and require multiple passes, even for simple grooves.

For large projects that involve heavy or bulky materials, as well as parts that need cutting on multiple sides, it’s best to use a horizontal milling machine.

2. Shape

If you plan to work on smaller or intricate parts, such as dental prosthetics or electronic components, vertical mills may be the better choice. But if the shape of the materials that you’ll be working with is bulky or oddly shaped, a horizontal setup will work better for it.

3. Time

For projects that require fast and regular turnaround times, a horizontal milling machine is ideal. However, for less time-sensitive projects, a vertical machine is a cheaper and easier-to-use alternative.

4. Projects

If you want a machine that is versatile enough to handle different types of projects, choose one that can perform a broad range of tasks. This is especially important if you don’t have the budget to purchase multiple machines or add-on parts.

5. Budget

Vertical milling machines can be a good option for those with limited funds as they are typically cheaper to acquire than horizontal mills. However, it’s suggested to assess your current and future projects along with the type and weight of materials your milling machine is expected to handle.

Although vertical machines may seem like a more cost-effective option, you should ensure that the materials you use are not too heavy or thick, as this could ultimately result in increased expenses due to equipment repairs or replacements. Finally, be sure to factor in the cost of any cutting tools that will be required to complete your project when considering your budget.

Conclusion

Over the last twenty years, milling machines have rapidly progressed, making it effortless to create machine parts and offering numerous advantages. The contrast between modern vertical and horizontal milling is essential to make an informed decision when selecting a machine. This blog post provides the necessary information to help you make an exact choice. Or partner with Runsom Precision, a skilled manufacturer with the tools and experience to provide excellent CNC milling services and efficiently complete your project on time.

An Expert Offering CNC Milling Solutions – Runsom Precision

If you require custom parts for your project or business but do not want to invest large amounts of money in equipment, a CNC machining service may be the solution for you. Runsom Precision specializes in CNC milling to produce precise and high-quality custom parts designed to your exact specifications. Our focus is on crafting intricate details and ensuring superior final products. Get an instant quote today!

Other Articles You May be Interested in: