In view of its inherent features, the oil and gas industry always demands highly robust precision components that can withstand harsh working and external conditions. Runsom has recognized that and consistently pursues the demanding durability, tolerance, and reliability required in this field. With extensive experience in partnering closely with the top oil and gas companies around the world, we have earned a good reputation for high levels of accuracy, precision, and efficiency and are firmly trusted by our customers. We are delighted to face and tackle all of the challenges and committed to making high-quality parts that can be used in the most challenging tasks.

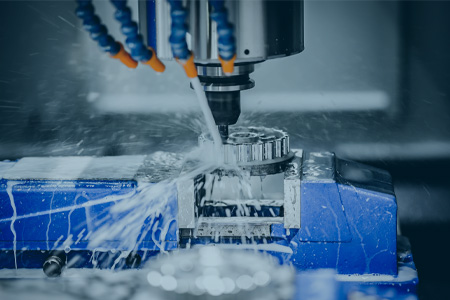

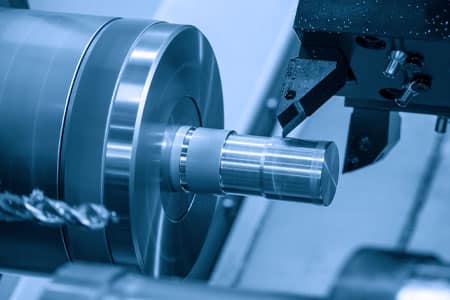

With the rapid development of technology and growing demands in the oil and energy industry, we continuously forge ahead to meet our clients’ needs and help them boost their business with our agile supply chain and state-of-the-art CNC machining services. Paired with our exceptional CNC machining equipment, our skilled engineers and machinists are ready to work with you closely to produce machined parts and components for offshore rigs, pipelines, and drilling equipment. Products fabricated from Runsom can be found in massive oil and gas applications, such as refinery distribution networks and refined product delivery systems. Our mission is always to keep innovation and develop new technologies to promote the industry and benefit our customers mostly.

Benefits of Precision Machining to Oil and Gas Industries

The reason why components applied in oil and gas equipment typically tend to be built with strict standards and specifications is that they must be subjected to unexpected situations and potentially dangerous compounds like high temperature or pressure and corrosive chemicals. Even a slight variation in the size or shape of a part may affect its features and performance, which could pose threat to human or operation safety in turn. Thus it can be seen that precision CNC machining plays a crucial role in the oil and gas industries.

The benefits of CNC machining can be shown in the following aspects:

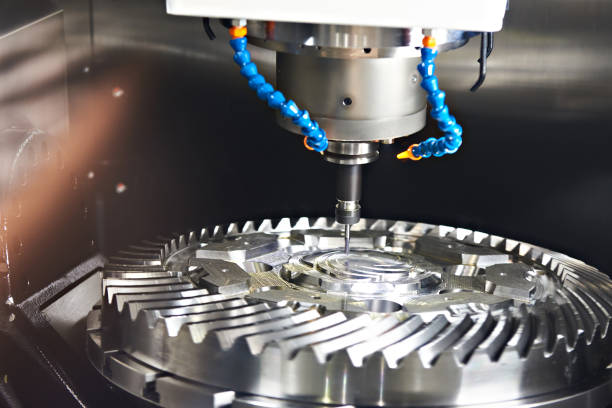

A CNC machine follows the instruction of a computer to execute the operating processes in a preprogrammed pattern, which ensures the exact size, geometry, and tolerance of the product are created to the same specifications needed by clients. So accurate are these parts made that their tolerances are as low as 0.0005 inches.

Experts at Runsom have recognized these essential demands in the oil and gas industry. They master the comprehensive knowledge of CNC machining for the oil and gas industry paired with the assurance of high precision offered by top-notch CNC machines.

CNC Machining Services for the Oil and Gas Industry

Oil field and energy experts firmly trust Runsom to deliver their parts in consistent quality due to the assurance of reliable technical support and the leading-edge CNC machining process. Our CNC machining services available for the oil and gas industry include:

Typical Materials We Work With

Alloys

Copper

Special Alloys

Components performed in the oil and gas heavy machinery are commonly subjected to unexpected variations when put into usage. Hence, materials used for precision machined components generally have some superior characteristics and the closest tolerances, as well as demanding finishes. Extremely harsh situations are as follows:

- Strong chemicals

- High pressures

- UV solar radiation

- Mold and other microbes

- High temperatures

- Dust and dirt

- Moisture and humidity

- Electromagnetic interference (EMI)

Post Processing for CNC Machined Oil and Energy Parts

There are various surface finishing and secondary operation choices to help you enhance the functional or aesthetic properties of your CNC machined components for the oil and gas industry, including:

Plating

Powder coating

Heat treatment

OD and ID grinding

Types of Parts Machined for Oil and Gas Applications

We possess a professional team of machinists at our organizations to design and manufacture the components for the oil field and energy industry. Meanwhile, backed against the latest pieces of facilities at our CNC machine shop, our technicians can deal with the most challenging of jobs and accommodate the specification our clients wanted. All these capabilities enable our parts widely to be used in massive equipment in the oil and gas industry.

We provide CNC machining for the following kinds of parts and components:

- Pins

- Spacers

- Springs

- Shafts

- Fasteners

- Connectors

- Bushings

- Vacuum Barriers

- Valving Systems

- Sealing Systems

- Actuating Systems

- Pumps Systems

- Drill Bit Parts

- Stuffing Boxes

- Blowout Preventers

- Hydraulic components

Our Advantages in CNC Machining Oil & Gas Industry

Oil & Gas Precision CNC Machining Services

When it comes to customizing precision CNC machined parts for the use of highly sophisticated pieces of equipment for mining and refining in the field of oil field and energy industry, Runsom can always make difference to scale our customers’ requirements and improve their applications with our exceptional manufacturing capabilities and the skills of our dedicated staff members.

We have the capability to complete needed volumes whether for one piece of prototype or large-volume production up to 10,000 pcs. Just simply clarify your requirements, we will spare no effort to deliver the high-quality parts exceeding your expectations while realizing your deadlines within the agreed budget. At Runsom, you will have the chance to experience excellence at every stage of our work.

Send us your RFQ to see how we speed up your oil and energy project.