Nowadays, communication technologies are vital in our daily lives, and their significance will only continue to grow as global connectivity increases. To enhance performance and reliability, industry experts have made extensive efforts to improve both individual components and overall systems. Among these endeavors is a focus on the use of high-quality components, as they can significantly impact the proper functioning of a system.

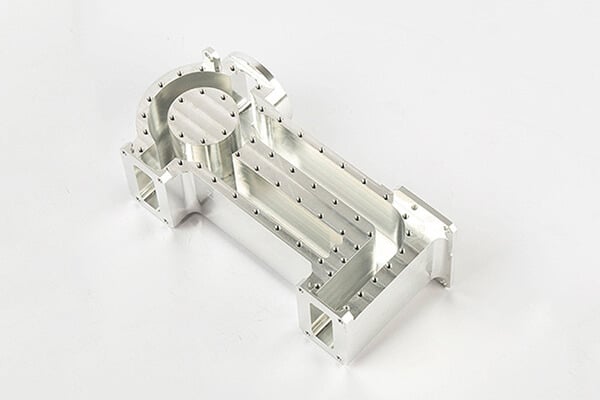

In the communication industry, CNC machining plays a crucial role. This process involves using a computer system to control and operate machines. While primarily used for metal machining, CNC milling cutters can also be utilized to manufacture products from various materials. By employing CNC machining, engineers can fabricate numerous precise components for communication equipment, leveraging the versatility of working with multiple materials and accommodating complex designs.

Here, we’ll discuss the role of CNC machining in the communication industry, the advantages of using CNC machining for making communication equipment components, materials, and applications of CNC machined parts for communication applications.

The Role of CNC Machining in the Communication Industry

CNC machining creates intricate components that are essential for supporting the fast-paced and ever-evolving communication industry. The reliability of telecommunication equipment and system heavily relies on the use of high-quality parts, otherwise, resulting in consequences such as malfunctions, call disruptions, low-quality video transmission, and satellite broadcasting power failures.

CNC machining proves to be an ideal manner to achieve precise manufacturing in the telecommunication equipment sector. Computer technology enables the design and production of complex and specialized parts. CNC machinists can utilize various innovative processing technologies to effectively manufacture even the most intricate components.

The precise nature of computer-controlled production in CNC milling enables the support of innovative design for intricate and accurate products. The CNC method allows for the easy formation of parts from high-strength materials such as stainless steel, steel, brass, and aluminum. Moreover, CNC machining is highly efficient, facilitating the production of a large number of orders in a short period of time.

As the communication and telecommunication industry continues to advance, the demand for evolving components also increases. The mobile industry, for instance, is rapidly transitioning from 4G to 5G technology, which necessitates the production of complex prototypes. To keep pace with current and future technologies, the manufacturing of communication equipment components through CNC machining must constantly update and adapt.

Advantages of Using CNC Machining for the Communications Industry

CNC machining allows for manufacturing components of exceptional quality, boasting enhanced levels of accuracy, precision, and consistency compared to conventional methods. As a result, it significantly improves quality control and helps reduce costs associated with product development. Furthermore, CNC machining increases production throughput and facilitates faster turnaround times for components.

1. Higher design flexibility

CNC machining offers telecommunications industry manufacturers the advantage of broader design flexibility. This means they can transform a diverse range of designs into tangible objects using parts and products that are customized to cater to specific and unique requirements, such as accommodating high-volume data capacities, withstanding variable weather conditions, or meeting zero-lag demands. Consequently, this freedom allows for generating more innovative solutions within the industry.

2. Increased efficiency and lower costs

CNC machining serves as a highly efficient and cost-effective method for producing precision components utilized in various communication products, including RF connectors, switches, antennas, adjustable attenuators, and more. By employing CNC machining, manufacturers can effectively reduce costs related to product development by minimizing waste typically attributed to traditional manual machining processes.

3. Higher precision and accuracy

CNC machining not only provides higher accuracy and precision but also delivers enhanced consistency in product designs, along with improved quality control when compared to traditional methods. By employing precision machining, components can be manufactured to tight tolerances, exhibiting minimal variation from piece to piece and batch to batch. These characteristics are crucial in ensuring the reliability of communication equipment, preventing malfunction issues that may arise from improperly machined components used in these devices.

4. Greater material suitability

CNC machining offers wider material suitability, as it can easily accommodate high-strength materials like aluminum, brass, steel, and stainless steel. This ensures that manufacturers have the flexibility to incorporate these materials into their designs without concerns.

5. Better scalability and faster turnarounds

CNC machining provides better scalability and faster turnaround times. It is well-suited for projects of any size, making it highly adaptable. Its efficiency allows for increased production throughput, enabling the production of high volumes of parts within a short lead time, all while maintaining quality standards.

Materials for CNC Machining of Communication Parts

The telecommunication industry is widely recognized as a rapidly evolving sector for economies worldwide. Countries like America, China, and India are investing heavily in the mobile phone industry, striving to meet the increasing demand from consumers. To achieve this, optimizing and automating manufacturing processes become crucial. This is where CNC machines and software come into play, facilitating the fabrication of parts in an efficient manner.

Now, let’s go through the materials primarily utilized in CNC machining of communication equipment parts.

Copper

Copper is the dominant and durable material used in communication networks for wires and cables. It is chosen for its excellent conductivity, high ductility, and low hardness. In fact, copper exhibits similar conductivity properties to silver, making it highly desirable for cable production. Consequently, cables made from copper are regarded as high-grade and top-quality due to their exceptional properties.

Beryllium Copper

A composite material comprising copper and beryllium is utilized in the communication industry to meet the demand for stronger and more ductile wires. This material is chosen in situations where increased wire hardness is required. Its exceptional hardness enables it to withstand higher levels of strain and pressure compared to other materials. As a result, it finds common application in high-traffic areas, particularly for high-density cables and connectors.

Brass

Brass, an alloy composed of copper and zinc, is softer compared to beryllium copper. However, it possesses commendable conductivity and flexibility, rendering it well-suited for communication applications. While brass may have lower strength and ductility leading to its limited usage in heavy-duty applications, its advantage lies in its lower cost relative to other materials.

Steel

Steel is a crucial metal in the communication industry. Its high tensile strength and hardness make it an excellent choice for wiring purposes. These properties make it ideal for industrial applications, including electrical appliances, telecommunication, and other networking components. Notably, steel possesses low ductility, endowing it with resistance to corrosion and abrasion.

Aluminum

Another metal commonly utilized in the manufacturing of communication wires and cables is aluminum. Like copper, aluminum is an excellent conductor of electricity. However, its cost is lower compared to copper, making it a cost-effective alternative, particularly in applications where budget considerations are prioritized. Aluminum possesses high strength and low ductility, making it well-suited for networking purposes.

Plastic

Plastic stands as one of the most commonly employed materials in the communication industry. Its versatility allows for varying densities and the ability to be molded into different shapes to meet specific requirements. Lightweight and highly durable, plastics are well-suited for wiring applications. Additionally, they can be combined with other materials to enhance strength and flexibility.

CNC machining is employed extensively in the communication industry. It serves a vital role by enabling the production of detailed electronic modules, catering to the rapid demand within the industry. The application of CNC machines contributes to the manufacturing of telecommunication and electronic equipment with exceptional precision, optimizing manufacturing practices. These machines ensure optimal results and facilitate the fabrication of intricate and complex parts. The combination of advanced processing expertise and equipment enables the efficient creation of complex designs.

Applications of CNC Machined Parts for the Communications Industry

Communication systems and telecommunications devices comprise a wide array of components that collaborate to facilitate information transmission, reception, and processing. To ensure their proper functioning, many of these components necessitate meticulous design and construction, often achieved through precision machining processes. Some examples of such components include:

- Routers

- Satellites

- Chipsets

- Switches

- Modems

- Shielding

- Heat sinks

- Cell phones

- Panel frames

- Residential gateways

- Amplifier housings

- Antenna components

- Microwave tower parts

- Wireless infrastructure equipment

- Landline infrastructure equipment

Conclusion

CNC machining has a crucial position in facilitating the rapid growth and transformation of the global communication and telecom industry. With its precise fabrication capabilities, CNC machining ensures the production of critical machine components that are necessary for reliable operation in telecommunication systems, equipment, and mobile towers. Dependence on high-quality parts is paramount as substandard components can result in equipment failures, leading to significant financial losses and disruptions in communication services. Therefore, CNC machines are highly sought after for manufacturing intricate and precise components that the communication industry demands.

Partner with Runsom Precision on Your Next Communication Industry Project

Are you in need of a reliable partner for your next project in the communications industry? Look no further than Runsom Precision! Our expert team and advanced CNC machining service for communication industry have been extensively utilized in producing machined parts for various aspects of communication products, including portable control units, pedestal parts, reception devices, tracking systems, and antennas.

At Runsom Precision, we offer rapid prototype manufacturing and low-volume manufacturing services, allowing for a quick turnaround on your projects. We also provide surface finishing options for aesthetic purposes, ensuring full support for your communication product needs. Request an instant quote to get started on your next communication industry projects now!

Other Articles You May Be Interested in: