Runsom Precision- Custom Precision CNC Machined Components Manufacturer

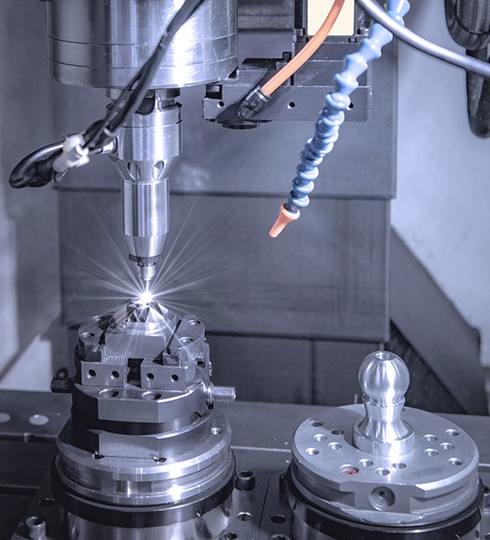

CNC precision machining makes it possible to reach precision machining of complex geometric details but reduce setup and production costs at the same time. As a highly developed and reliable technology, precision CNC machining largely minimizes human engagement and interference in the manufacturing process, and in turn, the overall degree of accuracy and efficiency is guaranteed and improved.

If you want the best results for your machined parts, it's of great significance to work with a reliable CNC machine shop with incredible in-house manufacturing capabilities. Runsom Precision has a team of highly skilled specialists and machinists with extensive experience in precision machining technology. Equipped with 3-, 4-, and 5-axis CNC machines, we are ready to customize a broad variety of high-quality and complex metal and plastic products to help you keep competitive in the industry.

What Is Precision CNC Machining?

CNC precision machining involves the process of making parts with tight tolerance and complicated geometric details by cutting and shaping raw materials. Computer-aided Design (CAD) and Computer-aided Manufacturing (CAM) blueprints help instruct the proper cutting process. These programs are essential and indispensable during the design phase as they often contain detailed 3D contours to ensure successful part building.

High-precision machining now plays a significant role in the manufacturing industry, which needs the cooperation of highly skilled designers and engineers. Designers created designs at first and then transferred them into manufacturing instructions. The machinists then send the final coded instructions in machine language to the CNC equipment to start the manufacturing process.

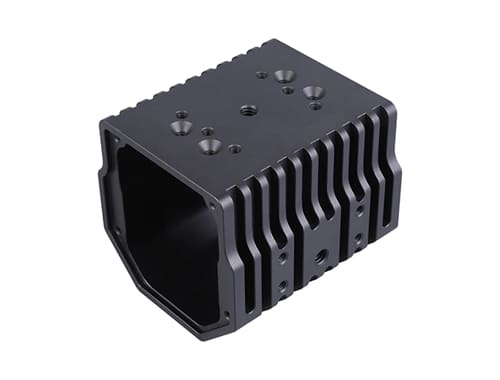

Moreover, some core sectors require precise machining to manufacture components that function instantly and fit well into their assembly, such as surgical instruments, aerospace components, automotive accessories, optical parts, etc. The use of advanced precision machine tools in the precision machining process will facilitate the creation of complex parts with sophisticated geometries. A typical CNC machine can achieve a tolerance standard of +/- 0.005 inches. However, a tolerance of +/- 0.002 inches to +/- 0.0002 inches can be reached when using CNC precision machining.

Advantages of High Precision CNC Machining

Precision CNC machining can achieve higher productivity because it improves machining automation and programming capabilities without interrupting the use of the machine. High-precision machines with excellent accuracy offer repeatable results in good quality.

The CNC machine can run programs created offline while traditional machining involves manual monitoring and adjustment of tools and running speeds. One machine operator can do multiple works including changing over machining centers, running various productions, maintaining load parts and tools, and performing offline deburring and quality control.

Therefore, this structure doesn't need so many operators during the monitoring process, in turn, largely saving labor costs. Likewise, it speeds up the creation of parts.

The parts quality made from CNC precision machining is incredible. The use of computer numerical control eliminates any variation occurred in traditional machining.

The process can run for hours with minimal maintenance and advanced software to fit design requirements. Hence, even the most intricate parts can be manufactured with advanced processes to ensure the highest quality beyond customer expectations.

While some machining still uses traditional methods, some applications require high-precision machining to promise tight tolerances.

Additionally, most industries need to mass produce identical parts. This is only possible with the repeatability of precision CNC machining, ensuring that all parts maintain equal quality.

Your prototype production is even more efficient when employing CNC machining technology. You don’t have to spend a lot on prototypes since there are extensive cost-effective materials available for CNC machining. Certainly, the entire production process will speed up when prototyping is faster.

At Runsom, the prototypes we delivered all match quality standards and manufacturing requirements. Learn more about our rapid prototyping capabilities.

Our Precision CNC Machining Capabilities

Runsom Precision is a reliable and trusted supplier offering CNC precision machining services for global customers across a wide range of industries, including medical, aerospace, automotive, electronic, optical, and food processing industries, etc. We are ready to handle your order and precision CNC machining projects in a fast production cycle with rich materials stock and all kinds of surface treatments.

Our machine shop has settled top-notch equipment, allowing access to the advanced CNC milling machines available in sizes up to 84 inches on the X-axis and 50 inches on the Y-axis, as well as 3-, 4-, and 5-axis verticals.

Types of CNC Machine

3-axis Milling Machine

A 3-axis milling machine refers to manually milling a workpiece along the x-, y-, and z-axis. The 3-axis system remains stationary when the tool operates while other machines notably have a moving bed. These models are versatile and precise machines designed for well-defined holes and slots and the milling of sharp edges.

While this type of milling has the capability of producing the same product as 4- and 5-axis milling, 3-axis milling has a limited level of detail and efficiency compared to 4- and 5-axis machines.

4-axis Milling Machine

A 4-axis machine contains the same 3-axis’ mentioned above but adds a rotation around the X-axis, called the A-axis. While its capabilities are not comparable with more advanced 5-axis machines, it remains one of the most popular milling options and is well-suited for many designs, research, and prototyping.

Just one step away from the most advanced milling machines, 4-axis milling machines execute operations vertically and function in a high-volume fashion. These machines offer better capabilities than 3-axis machines with a higher level of detail handling.

5-axis Milling Machine

At present, 5-axis CNC machines are the milling machines with the highest efficiency and precision on the market. In addition to traveling along the x, y, and z linear axes, the 5-axis machine can rotate on two (A and B) axes, enabling the tool to approach parts from any direction.

Outperforming both 3-axis and 4-axis machines, 5-axis CNC milling machines can achieve incredibly complicated geometries with high precision. Runsom Precision has extensive experience in offering 5-axis CNC machining services that reach an angular tolerance of two in a thousandth of a degree (.002°) with outstanding surface finishes and quality at a rapid production run.

Materials Available for Precision CNC Machining

The precision machining process is applicable to a broad array of materials. In general, common materials available for CNC machining can be classified as below:

Some basic or engineering plastic materials are frequently applied to precision CNC machining to generate high-quality products at competitive prices.

Plastics commonly used for CNC precision machining are:

- Acrylonitrile butadiene styrene (ABS)

- Polycarbonate (PC)

- Poly(methyl methacrylate) (PMMA)

- Polyoxymethylene (POM)

- Polyamide (PA)

- Nylon

- Peek

- Polystyrene

- Polyethylene

- PTFE/Teflon

In most cases, Runsom works with the most common materials for CNC machining. But if you have special requirements for the material, we can help to provide a custom solution to meet your precision machining needs.

Precision CNC Machining Applications

Due to its versatile, cost-saving, and efficient process, precise machining is increasingly gaining more prominence in the manufacturing sector.

Industries that benefit from the precision machining process include:

Medical Industry

The medicine industry is quickly developing with the need arising for new equipment. And the equipment used in the healthcare sector needs the highest grade of accuracy and quality to function perfectly in each surgical operation. Instruments or tools such as safe enclosures, implants, MRI matches, orthotic devices, and many more generally require close tolerance. As such, precision CNC machining can make sense.

The medicine industry is quickly developing with the need arising for new equipment. And the equipment used in the healthcare sector needs the highest grade of accuracy and quality to function perfectly in each surgical operation. Instruments or tools such as safe enclosures, implants, MRI matches, orthotic devices, and many more generally require close tolerance. As such, precision CNC machining can make sense.

Aerospace Industry

Aerospace vehicles require highly precise apparatus whether for transportation planes or space shuttles since a single mistake could cause severe damage to different aviation vehicles. The CNC precision machining is perfect for the manufacture of a series of components in this industry, such as bushings, manifolds, landing gear ports, wings, and more.

Aerospace vehicles require highly precise apparatus whether for transportation planes or space shuttles since a single mistake could cause severe damage to different aviation vehicles. The CNC precision machining is perfect for the manufacture of a series of components in this industry, such as bushings, manifolds, landing gear ports, wings, and more.

Automotive Industry

As auto companies come up with innovations to add to their latest car iterations, they have to develop prototypes of those parts before putting them into production. With CNC precision machining, it is practical to develop the exact specifications for these prototypes. This technology also produces parts for other transport vehicles, such as transport trucks, shipping boats, etc.

As auto companies come up with innovations to add to their latest car iterations, they have to develop prototypes of those parts before putting them into production. With CNC precision machining, it is practical to develop the exact specifications for these prototypes. This technology also produces parts for other transport vehicles, such as transport trucks, shipping boats, etc.

Military and Defense Industry

Ammunition and defense systems in various nations are always keeping updated, and precision CNC machining has never made more sense. The precise machining technology performs its effect on transforming all these designs into reality using a variety of materials and processes. Cases of components manufactured for this industry include aircraft parts, transportation components, ammunition, parts for communication devices, etc.

Ammunition and defense systems in various nations are always keeping updated, and precision CNC machining has never made more sense. The precise machining technology performs its effect on transforming all these designs into reality using a variety of materials and processes. Cases of components manufactured for this industry include aircraft parts, transportation components, ammunition, parts for communication devices, etc.

Precision CNC Machining FAQs

In brief, it’s a process of shaping chunks of material into highly precise parts, allowing them to meet each specification. Computer numerical control (CNC) equipment generally involve in this process to perform operations like cutting, milling, turning, and electrical discharge machining (EDM).

CNC machining is a type of precision machining, which is different in that it is automated and can achieve high CNC accuracy and extreme precision.

At present, 5-axis CNC machines are the milling machines with the highest efficiency and precision on the market. In addition to traveling along the x, y, and z linear axes, the 5-axis machine can rotate on two (A and B) axes, enabling the tool to approach parts from any direction.

The basic concept of CNC precision machining is that it involves a manufacturing process employing software to design the exact specifications of a product, and then process the raw material into that “mold” to produce the finished product.

The standard tolerance limit for CNC machining is approximately +/- 0.005 inches (0.127 mm), while precision machining can reach +/- 0.0002 inches (0.00508 mm).

Precision machining depends on the use of automated computer numerical control (CNC) machine tools to reach tight tolerances and create complex geometric cuts with a high level of accuracy and repeatability.

CNC machines can provide high levels of precision, helping you realize extremely close tolerances. No matter how complex your parts are, CNC precision machining may be the best technology of choice.

Start Your Precision CNC Machining Project Now with Runsom

Reach out to us directly to learn more about our precision CNC machining services or submit your RFQ online to quickly know how we can assist you with your precision CNC machining project.