China Best CNC Machining Automotive Parts Manufacturer

Runsom, a CNC machining automotive parts fabricator, serves global customers with the best CNC automotive manufacturing services. We can provide a perfect custom car parts solution for global customers including automotive manufacturers, autonomous driving technology companies, industrial heavy equipment manufacturers, OEM automotive component plants, and so on.

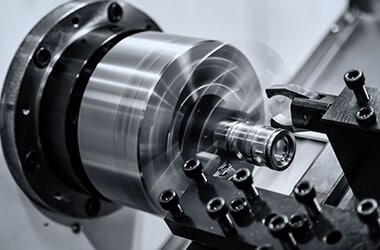

Our precision CNC automotive machining process enables us to deliver automotive parts with high quality and tight tolerance, no matter for both designing and producing vehicle prototypes or parts. To satisfy customers’ diverse demands, we keep ahead in the automotive manufacturing industry consistently and employ comprehensive manufacturing processes such as 3-, 5-axis CNC machining techniques for an array of complex automotive parts.

Facilitate the Way of Custom Auto Parts Fabrication

1. Improved Machining Process

Optimize manufacturing processes to create streamlined components assembly. Invest in advanced equipment and staff training.

2. Quality Assurance

Verify part geometry with several options for quality documentation. Inspection and testing with reports and certification.

3. Massive Supply Chain

Master superior production capacity and unmatched capabilities with developed supply chain and logistic options.

4. Mass Customization

Implement small batch manufacturing for more diversified and customized automotive features, tailored for the modern driver.

5. Rapid Prototyping

Refine your car parts with iterative rapid prototyping to minimize the design risk but not at the expense of development speed.

Materials Suit Best for Automotive Manufacturing

CNC Automotive Machining Process We offer

Runsom flexibly employs integrated manufacturing technologies with our advanced facilities to make on-demand car parts. Whether i’s from production-level plastic machining to precision metal machining or from simple milling or turning parts to complex and precision 5-axis CNC machining, we have rich experience to deal with all of that.

Precision CNC turned parts at the most competitive pricing, with fast lead times, and without requirements for minimum order quantity. The instant manufacturability feedback offered by Runsom’s professional technological team allows us to optimize your part designs for the CNC turning process and fulfill all requirements you need. Learn more...

Runsom has competitive markets in complex part manufacturing with ultra-precision 5-axis CNC machining with decades of incomparable innovation and experience. We are experts in true 5-axis machining, which enables us to quickly produce "almost impossible to make" 5-axis parts. Learn more...

Swiss CNC machining is a specialized process to machine small, high-precision turned parts. Precision Swiss CNC machining services are our specialty at Runsom. We can offer you suitable cost-effective solutions in Swiss-type machining and produce high-quality precision-turned parts. Learn more...

Advantages of Automotive Parts on CNC Machining with Runsom

1. Economical

Tailored production solution for your auto part CNC machining in the most cost-effective way

2. Exceptional Service

Let customers involve in every stage of the production process and solve problems on time

3. Efficient

Achieve rapid automotive prototyping & parts manufacturing for mass production

4. Durable Materials

High-quality and eco-friendly materials satisfy the requirement of your automotive applications

5. Great Accuracy

Highly skilled machinists and superior CNC machining centers ensure precision CNC machined auto parts

6. Massive Capacity

Exceptional capability in-house allows us to deal with all kinds of orders in large volume