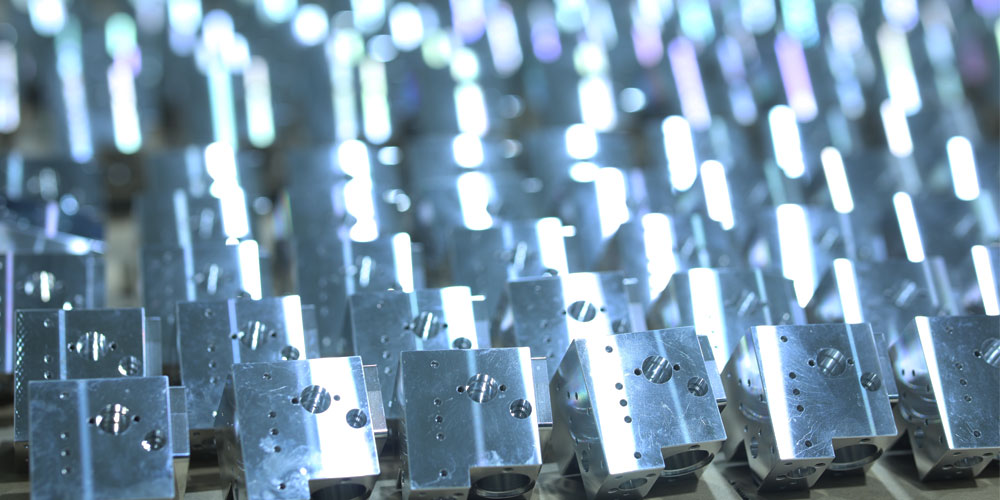

Aluminum is the most extensively used CNC material in the machine shop. It is widely used to developing various industrial products through manufacturing and prototyping. Concerning that, this guide will demonstrate some of the general characteristics of aluminum machining. Moreover, if you are a beginner, you will learn a lot about it.

Why Are Aluminum Alloys Easy-To-Machine?

Aluminum alloys are leading the world in the field of parts manufacturing and prototyping. These alloys possess high strength and excellent resistance against corrosion. Aluminum alloys are more accessible to machining than any other material and are much lighter than steel. Also, when it comes to enduring loads, aluminum is in no way inferior to heavy metals. But remember, heavy metals will be preferred wherever there is required high rigidity.

Aluminum alloys can be machined at high speed due to their soft nature and are highly conductive against heat, helping in the quick dissipation of the heat from the cutting zone and reducing wear and tear in the cutting tool, increasing its service life.

After machining, the final aluminum parts usually don’t require coating or painting to protect against corrosion because an oxide film is enough to protect it. However, some surface treatments can be done that we will see in one of the following sections.

Can We Use Aluminum for Prototyping?

The simple answer is Yes. Prototyping is suitable for the manufacturing of complex machine parts with extreme precision and accuracy. During the design and development stage of prototyping, one is not concerned about the technology and material selection. And at this stage, aluminum machining plays a vital role in developing products through rapid prototyping. It is mainly suggested for developing metal prototypes.

Aluminum is stronger and more robust than other metal alloys like brass and copper, and these metals possess high machinability compared to steel and titanium alloys. In most cases, manufacturers prefer to machine aluminum for developing metal prototypes.

Suitable Surface Treatment Methods for Aluminum Prototypes

A workpiece produced by aluminum is already protected against corrosion due to the oxide film on the material’s surface. Nevertheless, there are also some other surface treatment techniques for aluminum prototypes. For example, a standard paint can get used for surface coating, which is also available in a different variant that provides an attractive look to the final part and protects against adverse environmental effects.

Another method used for surface treatment is anodizing. In this process, the aluminum workpiece is attached to an electrical circuit to remove the surface’s impurities. This process generates microscopic pores on the material surface, increasing the depth of the oxide layer and the resistivity of the aluminum alloy against corrosion. Additionally, a paint coating can also get applied to fill those generated pores on the material surface. The outcome of this process will be a great matted-surface of your desired color.

Grinding and polishing can also be done to produce a mirror-like surface. High accuracy and precision can be achieved through grinding by removing the burr from the material’s surface. Whereas polishing can create a shiny and smooth surface, providing a polished metallic look to the manufacturer.

Different Applications of Aluminum Machined Parts

Due to their lightweight, the aluminum machined parts are generally used for applications where movement is required. Accordingly, they are widely used in automobile companies to produce light vehicles for better fuel efficiency. They are also used in aerospace and nautical industries.

Because of their resistive ability against corrosion, they are also used in developing marine structures. Likewise, it is a perfect choice for the manufactures and the builders. Household items such as practical appliances (iron, pans, etc.) also consist of aluminum parts due to their high thermal conductivity.

Aluminum alloys have high thermal and electrical conductivity, making them eligible for electronic devices. It can also get used for wiring purposes.

Specific Parameters for the Aluminum Machining Process

Some significant specifications must be considered during aluminum machining. You need to adjust the following parameters before machining the aluminum alloys.

- The speed of the spindle is over 12,000 rpm (it provides smooth surface finishing).

- A tool with 2 or 3 flutes is used in this process.

- Keep your feed rate at high speed.

- Make proper arrangements for using coolant.

- Use soft fixtures.

- Always counter-check the chip removal.

- Use carbide tip tools for aluminum machining.

- Make sure that your chip conveyor is working.

After adjusting the parameters mentioned above, the machining can be performed over the aluminum alloys.

Final Words

After a detailed discussion on aluminum machining, we concluded that it is the most suitable for the prototyping process. Aluminum possesses some extraordinary abilities such as resistance against corrosion, lightweight, easy machinability, and high strength. Most companies prefer aluminum machining for the quick production of prototypes and will increase their market demand.

Different surface treatment techniques can get used to obtaining high surface quality. Paint, grinding, and anodizing can be done to improve for that reason. Aluminum parts are leading the world through their high mechanical and chemical properties. They are extensively used in every industrial sector, especially in the automotive and aerospace industries.

The aluminum should only be machined with specific parameters such as high feed rate, high spindle speed, coolant availability, and suitable tool selection. When performed at a low feed rate and low spindle speed, the chip removal will become hard, producing poor surface quality.

Finally, we concluded that more than 60% of manufacturers prefer to use aluminum to develop a prototype. Only highly trained personals are allowed to carry out the machining process. The process can be performed on a manual lathe machine or CNC machine, whereas the final product’s quality is excellent in the parts produced by CNC machining.