The CNC machining process involves utilizing computer software to program the movement of production equipment and tools. This method is commonly employed to operate complex machinery such as mills, lathes, CNC routers, and grinders. With CNC machining, it’s possible to complete three-dimensional cutting tasks using a single set of instructions.

Currently, there exist various types of CNC machines on the market, each differing in their mode of operation, cutting tool, materials, and the number of axes they can cut simultaneously. This article aims to offer guidance on the different types of CNC machines available based on different classifications and explain how to select the most suitable CNC machine for your needs.

13 Types of CNC Machines Based on the Function

CNC machines can be classified in various ways, one of which is based on their design and function. In this section, based on this classification, we will explore different types of CNC machines, their respective uses, and the limitations of each type.

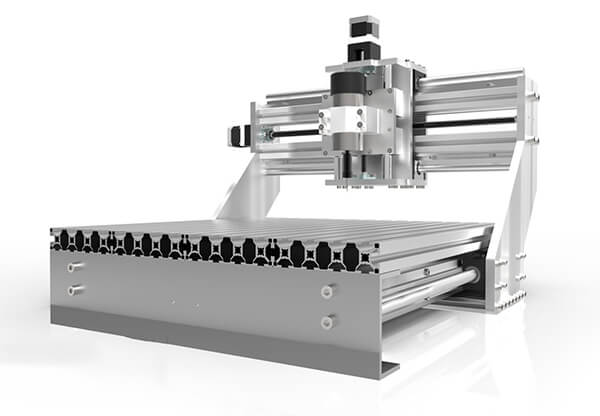

1. CNC Router

A CNC router is a machine that shares similarities with a CNC mill. However, it is typically used for machining softer materials and may have slightly lower precision compared to CNC mills.

A typical CNC router consists of components such as a mechanical base, power supply, spindle, stepper drivers, stepper motors, and controllers. When compared to traditional machining methods, CNC routers offer advantages such as increased productivity, improved accuracy, and reduced material wastage, allowing for faster production of products.

Similar to CNC mills, CNC routers are available in various axis configurations, ranging from three to six axes. Entry-level CNC routers often utilize a 3-axis system to carve workpieces into desired shapes. Additionally, a rotary tool attachment (4-axis) can be separately purchased to process curved workpieces.

CNC routers excel in utilizing computer numerical control to route spindle and machine tool paths, enabling the shaping and design of various materials such as aluminum, steel, plastic, wood, composites, and foam, to achieve the desired final design and shape.

Applications

CNC routers are highly versatile machines suitable for cutting intricate shapes, widely used for various applications, including:

- Carved wood furniture

- Moldings

- Interior and exterior decorations

- Door carvings

- Signage

- Musical instruments

Limitations

However, it’s important to note certain limitations of CNC routers, such as:

- High noise levels: Due to the presence of components like spindles, extraction systems, and vacuum systems, CNC routers can generate significant noise during operation.

- Residual dust: Working with CNC routers often results in the production of a considerable amount of wood or metal dust, leading to potential dust-related challenges in the working environment.

Cost

Regarding the cost of CNC routing machines, their initial prices typically range between $3,000 and $100,000. The hourly rates for CNC routing work are similar to those of CNC milling machines.

2. CNC Drilling Machine

CNC drilling machines are automated drilling machines with the ability to make precise and intricate holes in workpieces. They are equipped with mechanical rotating drill bits that penetrate the workpiece radially to create cylindrical holes. The design of the drill bit allows the waste material, known as chips, to fall away from the workpiece. Various types of drill bits are available for different applications, including screw machine drills, peck drills, spotting drills, and chucking reamers.

A CNC drilling machine automatically controls parameters such as spindle speed, feed rate, plunge rate, and depth of cut, based on the instructions provided by the CNC programmer. These machines can process materials at much higher speeds compared to traditional manual drilling techniques. These machines are equipped with intelligent tool-swapping and positioning technologies, which contribute to their increased productivity.

Applications

CNC drilling machines find applications in various industries, including:

- Automobile manufacturing

- Shipbuilding

- Astronautics

- Engineering machinery

- Mold making

- Woodworking and furniture making

Limitations

CNC drilling machines do have certain limitations to consider:

Dimensions of the hole: CNC drilling has limitations in terms of the dimensions of the holes it can create. It may not be suitable for creating deep or large holes. Moreover, different hole diameters require specific-sized drill bits.

Cost

The average cost of CNC drilling machines is about $25,000.

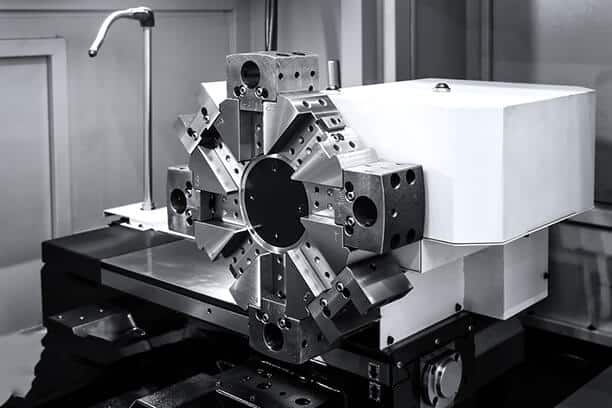

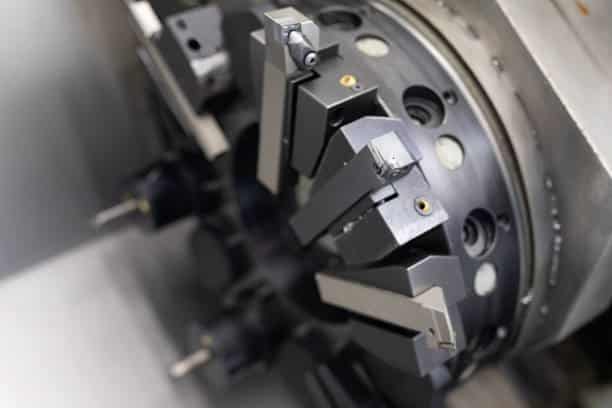

3. CNC Lathe

CNC lathe machines utilize single-point cutting tools to remove material from a rotating workpiece and shape it according to the desired specifications. Compared to manual lathes, CNC lathe machines offer improved speed and precision in finished product making.

These machines are well-suited for a variety of processes, including cutting, drilling, turning, sanding, facing, knurling, and more. In CNC turning, a non-rotary tool moves linearly along a rotating workpiece to create a helical or spiral cutting path. Different types of CNC lathes available in the market include turret lathes, engine lathes, and specialized lathes designed for specific purposes.

Applications

CNC turning machines have a wide range of applications across various manufacturing industries. Some common examples include:

- Camshafts

- Automobile parts

- Gun barrels

- Crankshafts

- Baseball bats

- Musical instruments

- Dining tables

- Furniture legs

Limitations

CNC lathes have certain limitations to consider, such as:

Symmetrical nature: These machines are typically suited for creating symmetrical components and may not be suitable for producing custom asymmetrical shapes.

Cost

The initial cost of CNC lathes can start at around $15,000, with prices increasing based on machine specifications. The hourly rate for using a CNC lathe typically starts at around $40 per hour.

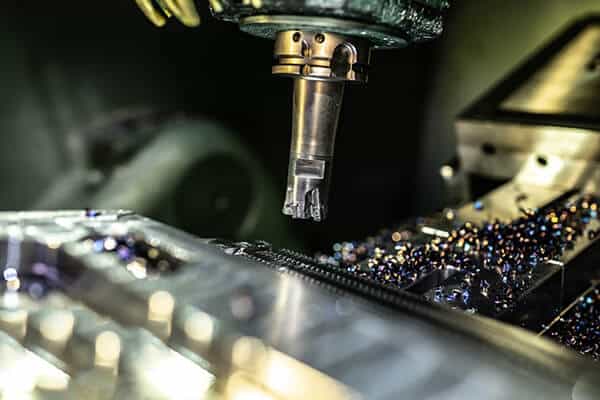

4. CNC Milling Machine

CNC milling machines utilize high-speed rotating multi-point cutting tools to accurately remove material from a workpiece typically held in place to make desired shapes.

CNC mills are equipped with a diverse range of cutting tools, each serving a specific purpose. Common examples of cutting tools used in CNC milling include drills, face mills, end mills, reamers, and taps. These machines are available in both vertical and horizontal configurations, as milling tools can be oriented either vertically or horizontally.

Applications

CNC milling machines have diverse applications and can be used in various industries for tasks such as:

- Cabinet making

- Furniture production

- Prototype modeling

- Signage production

- Manufacturing musical instruments

Limitations

While CNC milling is a highly effective technology that enables high-speed precision machining, there are some limitations to be aware of, including:

- Size Limitation: Each CNC milling machine has a maximum capacity for machining the size of the part, which relies on tool travel distance and machine enclosure size.

- Operator Skill: Skilled operators are required to operate CNC mills accurately, as operator errors can result in deviations in accuracy and design issues.

- Cost: Some users consider the initial cost of a CNC milling machine to be a limitation. However, it’s important to note that the benefits, such as precision machining, make it a worthwhile investment compared to alternative methods.

Cost

The cost of CNC mills can vary significantly. There are more affordable options available, starting from around $10,000 for home use. On the other hand, production workshops may invest over $200,000 in milling machines.

The hourly cost of CNC milling depends on the machine’s axis. For a 3-axis CNC machine, the average cost is around $40 per hour, while higher-axis machines can range up to $200 per hour.

5. CNC Plasma Cutting Machine

A CNC plasma cutter is capable of delivering precise and accurate cuts. It achieves this by utilizing an electrical discharge arc, similar to a plasma torch, which ionizes the air and melts the material at the point of contact with the electrical arc. However, the plasma cutting process is only suitable for electrically conductive materials, commonly used materials in plasma cutting including aluminum, stainless steel, steel, brass, and copper.

Applications

CNC plasma cutters are commonly used for:

- Automobile manufacturing

- Automotive repairs

- Fabrication shops

- Salvage and scrapping

Limitations

There are certain limitations to consider when using CNC plasma cutters:

- Materials: Plasma cutting is only suitable for cutting through metals and conductive alloys. This limitation restricts its use on non-metal materials such as wood and plastics.

- Heat-affected zones: Plasma cutting is a process that generates heat to melt the material, resulting in visible heat-affected zones (HAZs) on the cut area.

Cost

The initial cost of a CNC plasma cutting machine can range from $12,000 to $300,000, depending on the model and specifications. The average hourly cost of using a CNC plasma cutter is approximately $20 per hour.

6. CNC Laser Cutter

CNC laser cutters are similar to CNC plasma cutters in their ability to cut through tough materials. However, CNC laser cutters function using a highly focused laser beam, unlike plasma cutters that utilize ionized gas.

Due to the smaller point of contact and thermal spreading of lasers, CNC laser cutters generally offer higher accuracy and a superior surface finish than CNC plasma cutters. However, CNC laser cutters are typically more expensive than CNC plasma cutters with similar capabilities such as accuracy and cutting depth.

CNC laser cutters have a wider range of material flexibility and are commonly used for cutting various materials including plastic, paper, fabric, metals, and hardwood. Laser intensity can be adjusted based on the density and strength of the material, allowing for efficient cutting.

These cutters are known for their versatility in producing a wide range of designs, setting them apart from other cutting machines. The cuts and edges created by laser cutters are often incredibly precise and clean, eliminating the need for additional finishing processes. As a result, CNC laser cutters and engravers are premier choices for manufacturing machine components and engraving tasks. Laser engraving is particularly utilized in decorative works such as glass engraving, sign-making, and woodworking art.

There are various types of laser cutting machines available, categorized based on the type of laser medium used. These categories include gas lasers, liquid lasers, and solid-state lasers. The differentiation is based on whether the active laser medium is in a gas, liquid, or solid state, as well as the composition of the active laser medium (e.g., CO2, Nd: YAG, etc.). Among these, the two main types of lasers employed in CNC laser cutters are CO2 and solid-state lasers.

Applications

CNC laser cutting machines have a wide range of applications, including:

- Manufacturing aerospace parts

- Cutting automobile frames

- Producing medical equipment

- Engraving various materials

Limitations

There are a few limitations to consider when using CNC laser cutters:

- Limited thickness: Laser cutting machines have a maximum thickness limit for materials that can be cut effectively.

- Technical expertise: Operating laser-cutting machines requires highly skilled operators. Due to the potential hazards associated with laser beams, operators must have the necessary expertise to control the machine as the laser beam moves over the workpiece.

Cost

The cost of purchasing a CNC laser cutting machine can range from $5,000 to $300,000, depending on the specifications and capabilities of the machine. The average hourly cost of using a CNC laser cutter is about $20 per hour.

7. CNC Electrical Discharge Machine

CNC Electrical Discharge Machines (EDM), commonly known as spark CNC machines, utilize electrical sparks to manipulate and shape materials. The EDM process can also be referred to as wire burning, die sinking, sparks machining, or spark eroding.

EDM machines generate controlled sparks or electrical discharges that reach temperatures as high as 21,000 ℉ to vaporize the material and achieve the desired shape. The workpiece is positioned between two electrodes: the top and bottom electrodes.

Using the provided G code, the computer instructs the electrodes on the required amount of electrical discharge. This results in the generation of sparks that gradually remove material from the workpiece based on the specified design. To facilitate this process, dielectric fluid is used to flush or wash away the material consumed by the sparks, completing the machining process.

EDM stands out for its capability to create intricate slots, micro holes, and angled or tapered features that can be challenging to machine using traditional CNC methods. It’s a non-contact machining process because it employs sparks for cutting rather than bits or end mills. This non-contact nature makes EDM suitable for working on thin workpieces with complex designs and high precision that may deflect when subjected to cutting forces.

Applications

EDM cutting has various applications, including:

- Manufacturing injection molds

- Die casting

- Blanking punches

- Prototyping

Limitations

There are certain limitations to consider when using CNC Electrical Discharge Machines:

- Material constraints: EDM machines can only work with conductive materials and are not suitable for machining plastics, ceramics, wood, or other non-conductive materials.

- Slow cutting rate: The cutting rate of an EDM machine is relatively slow when working on corners and curves. This is due to the high electrode wear caused by recurring electrical discharges, resulting in slower overall production and increased costs.

Cost

The cost of a new CNC EDM cutting machine typically starts at $15,000. The hourly cost of operating these machines is about $25 per hour, with the cost of electrode wire being a significant component of the overall cost.

8. CNC Grinding Machine

A CNC grinding machine uses abrasive tools to achieve a smooth and precise finish on machined products. It is commonly used for components like transmission shafts, camshafts, ball bearings, and other workpieces that require an accurate and polished surface. Many parts produced using a CNC grinding machine have a cylindrical shape. Typically, the workpiece starts with a rough surface and is initially shaped using a CNC mill or lathe before being transferred to the CNC grinder for the final grinding operation to achieve the desired finish.

CNC grinders are available in various types, including cylindrical grinders, surface grinders, and roll grinders, among others. There is also a wide range of abrasive materials used for grinding, such as aluminum oxide, plated or vitrified CBN, ceramic blend grinding wheels, diamond grinding wheels, and many more.

Applications

CNC grinders have a broad of applications, including:

- Manufacturing high-precision gears

- Producing automobile parts

- Creating medical equipment components

- Manufacturing aerospace parts

- Tooling and precision machining

Limitations

There are limitations to consider when using CNC grinders:

Slow process: While CNC grinders offer precise material removal, they generally operate at a slower rate. This makes them unsuitable for applications that require shaping materials, as they are primarily used for finishing and smoothing surfaces.

Cost

CNC grinders tend to be relatively affordable compared to other CNC machines. The cost of surface, roll, or cylindrical grinders typically starts at $5,000. The operational cost of these machines is almost $20 per hour.

9. CNC Waterjet Cutting Machine

CNC waterjet cutters, as its name implies, utilize high-pressure jets of water, and in some cases, additional abrasive materials, to effectively cut through various materials. These waterjet cutters can handle both 2D and 3D cuts, and they excel at cutting materials with a high thickness.

CNC waterjet cutting is often chosen when working with materials that are fragile to high temperatures and can potentially melt, such as plastic and aluminum. While water alone can be used for cutting, the addition of abrasive materials like garnet or aluminum oxide to the water enhances the cutting efficiency.

In terms of cost, a CNC waterjet cutting machine is generally more expensive than a plasma cutter with similar specifications. However, it is relatively more affordable compared to a CNC laser cutter with comparable specifications.

Applications

CNC waterjet cutting finds applications in various industries and materials, including:

- Cutting foam, paper, stone, ceramic, glass, and sheet metal

- Mining industry

- Aerospace sector

- Automotive industry

- General fabrication

Limitations

There are a few limitations to consider when using CNC waterjet cutting:

- Cutting time: Compared to CNC plasma cutters and CNC laser cutters, CNC waterjet cutters tend to have slower cutting speeds, especially when dealing with corners and curved cuts.

- Component breakdown: Since waterjet cutters operate using ultra-high-pressure jets, there is a risk of cutter components breaking down, particularly when using lower-quality waterjet systems.

Cost

The cost of CNC waterjet cutters can vary widely, with prices starting at around $50,000 and going up to $200,000. The hourly operating cost of these machines typically ranges from $15 to $30 per hour, with the cost of abrasive materials being a significant portion of the total hourly cost.

10. CNC Pick and Place Robot

In the manufacturing industry, pick-and-place robots have gained significant popularity as they are specifically designed for repetitive tasks. These CNC machines require no manual handling of workpieces, reducing human interference and associated risks.

Typically, a pick and place robot consists of motors or actuators to control the movements of its robotic arm, along with a handler that securely grips the workpiece. The type of handler used depends on the nature of the workpiece: a clenching clamp is suitable for rigid and heavy workpieces such as automobile chassis, while a vacuum suction cup is preferable for delicate workpieces like glass panels.

Pick and place machines find extensive use in the production of computers, tablets, cell phones, and other electronic devices. When selecting a pick-and-place robot for your application, it’s vital to consider factors such as lifting capacity, handler type, and work envelope to ensure an optimal match for your specific requirements.

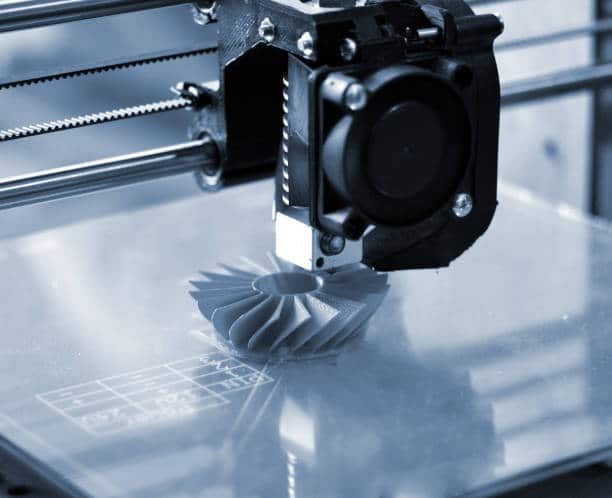

11. 3D Printer

A CNC machine known as a 3D printer is utilized for creating three-dimensional workpieces by layering material based on a digital design or model. To prepare the 3D design, an operator utilizes CAD software, which is then sliced into 2D layers by CAM software to generate the necessary commands for controlling the printing process.

The 3D printer, also referred to as additive manufacturing, differs from traditional subtractive manufacturing methods as it adds material rather than removing it. The material is typically heated and extruded through a nozzle in the print head, which precisely moves to deposit the material onto the work area, creating the desired part.

Primarily used for prototyping, the 3D printer CNC machine minimizes material wastage, as there is no need for excessive machining or removal of material.

12. CNC Machine with Automatic Tool Changes

An Automatic Tool Changer (ATC) is a variation found across various types of CNC machines. This feature enables the quick and efficient change of cutting tools within the CNC machine. It allows for the seamless transition between different types of cutting tools or the replacement of a broken or worn-out tool. The ability to automate the tool-changing process results in increased production speed and minimizes machine downtime.

CNC machines equipped with an automatic tool changer are a significant step towards achieving complete automation. Changing tools is often a bottleneck in CNC machining, but with an ATC, the machine’s tool carrying capacity and production rate are enhanced. It also improves the machine’s capability to work with a larger variety of tools.

13. CNC Bending Machine

A CNC bending machine is composed of a computer-controlled press and die, which exert the necessary pressure to bend the workpiece into the desired shape. Primarily used in the sheet metal industry, these machines accurately bend or crease metal sheets at pre-programmed angles. Furthermore, CNC bending machines can also be employed to bend metal rods and pipes.

In contrast to conventional bending machines, CNC bending machines offer exceptional accuracy in producing bends. Their capability to manufacture parts with precise dimensions and consistent results makes them highly desirable in various large-scale industries, such as metal fabrication, construction, automotive, and aerospace.

Types of CNC Machines Based on the Number of Axes

After determining the type of CNC machine, further classification is based on the number of axes used. Multi-axis machining is a specialized form of CNC machining that involves multiple axes of movement to achieve intricate geometries and precise tolerances.

For example, a CNC milling machine can be classified as a 3-axis, 4-axis, or 5-axis variant, each offering different capabilities and price points. Here are some of the commonly used types of CNC machines:

2-Axis CNC Machine

2-axis CNC machines are considered the simplest form of CNC system available. They consist of two axes of movement: the X-axis (vertical) and the Y-axis (horizontal).

These machines are primarily used for performing straightforward tasks such as creating straight-line cuts or drilling holes in boards. They are generally suitable for machining a single surface of a workpiece without the need for repositioning. The workpiece remains stationary during the machining process on 2-axis CNC machines.

3-Axis CNC Machine

3-axis CNC machines are the most widely used type of CNC machine. They encompass three axes of movement: the X-axis, Y-axis, and Z-axis (depth axis), allowing them to machine basic parts in 2.5 dimensions.

These machines can operate on all six surfaces of a square or rectangular block of material, but repositioning the block is necessary. Despite this, the workpiece itself remains stationary during the machining process on 3-axis CNC machines.

4-Axis CNC Machine

4-axis CNC machines are comparable to 3-axis machines but with the addition of an extra axis. In addition to the X, Y, and Z axes, a 4-axis machine features an axis of rotation.

This additional axis, known as the A-axis, enables the cutting tool to move along the X-axis in a rotational motion. Alternatively, the workpiece can be moved along the same axis. These machines are particularly useful for creating cutouts and performing cutting operations along arcs.

5-Axis CNC Machine

In 5-axis machining, an additional pivoting motion is incorporated, allowing the cutting tool or work table to move along the Y-axis. This pivotal and rotational axis is referred to as the C-axis.

These machines are known for their ability to simultaneously work on five surfaces of a workpiece without requiring repositioning, enabling them to efficiently make intricate and precise parts, particularly valuable in the production of medical and aerospace equipment.

7-Axis CNC Machine

A 7-axis CNC machine includes the three standard axes for moving the cutting tool, three axes for rotating the workpiece, and an additional seventh axis known as the E-axis, which rotates the arm holding the cutting tool.

These machines are commonly employed in the manufacturing of military equipment, aerospace, and medical, as they offer the capability to produce highly complex parts. The additional axes of movement provided by the 7-axis configuration enable advanced machining operations and intricate part designs.

9-Axis CNC Machine

9-axis CNC machines are a unique combination of a 5-axis milling machine and a 4-axis lathe machine. The milling machine is unique in its ability to work on the exterior surface of the workpiece to achieve the desired surface finish, while the lathe handles the completion of internal features.

This configuration allows a 9-axis machine to manufacture parts with both internal and external features. These machines are ideal for the production of dental implants, surgical tools, and complex aerospace equipment. The ability to perform both milling and lathe operations in a single setup offers enhanced versatility and efficiency in manufacturing processes.

12-Axis CNC Machine

12-axis CNC machines feature the most complexity in the industry, and they may be excessive for many applications. These CNC machines are equipped with two cutting heads that can move in all six axes – X, Y, Z, A, B, and C.

By incorporating dual cutting heads and utilizing all six possible axes, these machines offer a significant increase in accuracy. They have the potential to double production speed or even achieve higher levels of productivity.

However, it’s important to note that the utilization of 12-axis CNC machines is typically reserved for specialized and demanding applications where extreme precision and efficiency are paramount. For most standard applications, the complexity and cost of these machines may outweigh the benefits.

Types of CNC Machines Based on Motion Systems

The fundamental concept behind a CNC machine is to move the cutting tool and workpiece in relation to each other. The cutter is continuously repositioned and directed to its intended location. Various methods are employed for tool repositioning, resulting in three distinct types of CNC machines:

Point-to-Point Positioning System

The most fundamental type of computerized numerical control system is a Point to Point (PTP) CNC controller. In this control system, the cutting tool is directed to a predetermined point, at which point the machining process commences around that specific cutting point.

PTP systems are relatively low-cost and are commonly utilized for operations such as drilling, tapping, spot welding, and reaming, where simultaneous positioning and machining are not required.

Linear Positioning System

A linear positioning control system allows for the simultaneous repositioning of the cutting tool and machining of the workpiece. However, the movement is limited to being parallel to a single axis at any given time. Both the repositioning and machining processes are executed at a controlled rate. This control system earned its name due to the nature of the machining, which is performed in straight lines and does not accommodate curved cuts.

Contouring Path CNC System

The Contouring Path CNC system, also known as the Continuous Path CNC System, is the most costly among the three positioning control systems with the ability to create highly intricate parts. This system can perform both Point to Point (PTP) positioning and linear positioning. Furthermore, they can simultaneously control the positioning of the cutting tool in multiple axes.

This versatility allows for the creation of curved surfaces, often referred to as contours, on the workpiece. CNC machines such as mills, lathes, and grinders make use of this method for their operations.

Types of CNC Machines Based on Servo System

Based on the servo system, there are different types of CNC machine systems.

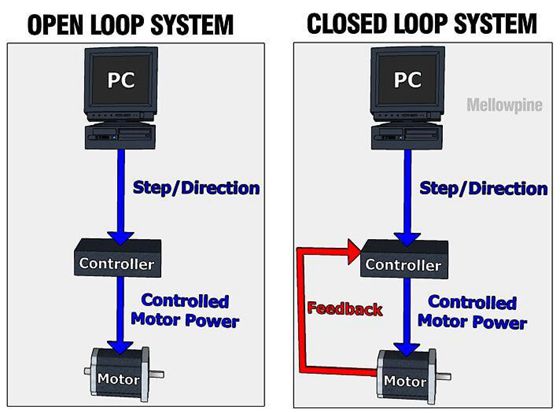

Open Loop Control System

In an open-loop control system, there is no detection or feedback device. The driving circuit amplifies the power, and the CNC device’s instruction signal is transmitted in a single direction to drive the stepping motor that moves the machine table.

One advantage of this system is its affordability, as it is relatively inexpensive. However, it has poor stability and accuracy, which can result in reduced work quality.

Semi-Closed Loop Control System

In a semi-closed loop control system, the actual displacement of the worktable is determined by an angular displacement detection device located directly at the end of the servo motor shaft or ball screw.

This detection device compares the calculated value with the original instruction displacement value of the worktable and adjusts accordingly based on the difference. This control system falls within a moderate price range but offers high precision and stability.

Closed-Loop Control System

In a closed-loop control system, a linear displacement-detecting device is employed, typically mounted on the moving parts or tabletop of the machine tool. The CNC device’s comparator receives the detected actual displacement and compares it to the programmed instruction value.

Ensuring stability in a closed-loop controlled CNC machine can be challenging. However, this type of machine offers high precision.

How to Choose the Right CNC Machines Types?

When deciding on the most suitable CNC machine for your company or projects, there are several factors that should be taken into account. The choice of CNC machine that best fits your requirements will depend on factors such as the nature of your business, the products you manufacture, and your production volume. Below are some considerations to keep in mind when choosing a CNC machine.

Material Considerations

When selecting CNC machines, it’s important to take into account the type of material being processed. Machines need to be strong and durable enough to accurately mill complex components from hard alloys. For softer materials such as mild steel, precision machines that can maintain the required tolerances may be suitable.

Business Types

The nature of your business will determine the available options for you. For instance, if you operate a small CNC machine shop, your needs may be fulfilled by a few CNC routing machines. However, if you oversee a large manufacturing company, you will likely require larger and more versatile machines.

Required Complexity

The type of CNC machine required largely depends on the nature of the work being performed. For simpler items, a CNC lathe or 3-axis milling machine may suffice. However, as complexity increases, it becomes more cost-effective to have machinery that can fabricate multiple components in a single setup. The most suitable machines for such tasks are five-axis CNC machines.

Additionally, certain product categories necessitate specialized CNC equipment. For example, a purpose-built Swiss lathe would be ideal for manufacturing thousands of intricate, cylindrical pieces.

Availability of Spare Parts

Like any other machine, CNC machines can experience wear and tear or malfunctions over time. To mitigate potential downtime, it’s crucial to select a brand or model that can be efficiently repaired by your specialists and has easily accessible spare parts for replacement. This is important because the availability of spare parts directly affects the amount of time you may have to wait before resuming production.

Power Capacity

These machines have high power requirements and often rely on three-phase power for optimal functioning. Therefore, it’s essential to ensure that the building has sufficient power capacity to accommodate the new equipment. It’s also advisable to assess the current power consumption. While the existing machines may currently operate within the available power supply, the addition of a new CNC machine might exceed the capacity and lead to power shortages.

Conclusion

In this article, different types of CNC machines based on different classifications were discussed, providing explanations of their functions, applications, limitations, how they are used in manufacturing, and how to select the most suitable CNC machine for your needs. It can be seen that there are numerous options available when it comes to CNC machines. Selecting the ideal machine for your specific requirements can be a daunting task, considering the numerous variety available. Additionally, CNC machines tend to be quite costly, making the initial investment a significant consideration.

Fortunately, there is an alternative solution. By outsourcing your CNC machining needs to reliable manufacturers like Runsom Precision, you can bypass the challenges of selecting and affording a CNC machine. At Runsom Precision, we possess a wide array of CNC machines, ranging from simpler 3-axis to intricate multi-axis machines, capable of handling any job. Our team of skilled engineers is ready to address your product needs, no matter how complex they may be.

So why wait? Contact us today or request an instant quote online, and let us begin working on delivering the optimal solution for your manufacturing needs.

Other Articles You May Be Interested in: