3D printing, often known as additive manufacturing, is a manufacturing method of creating parts by growing them from raw materials. In subtractive manufacturing, such as CNC machining, the bulk material is sliced or shaped to its final shape through forming or cutting.

Three-dimensional printing (3D printing) is a powerful technology for creating unique items with complicated geometry, serving various industries ranging from medical and automotive to defense and aerospace. Along these lines, in this article, we will discuss the anatomy of a 3D printer and how to get started with 3D printing. So, let’s dive straight into our discussion.

Anatomy of A 3D Printer

The following characteristics and terminology describe a 3D printer’s fundamental mechanics.

1. Effective Build Area/Bed/Platform

The 3D printer’s effective build area comprises the X and Y axes, which are the planes on which material is placed in successive layers. Moreover, it also includes the Z-axis, which is the vertical distance across which material can be cured, fused, or deposited.

2. Frame and Carriage

It’s the mechanical body of a 3D printer made of metal extrusions. To keep the printed pieces accurate, the frame must be very stable. 3D printing frames house the build platform, gears, heaters, screws, material feeds, and pulleys. Remember, it is not to be mixed up with the concept of exchangeable frames, which generally relate to the modular, replaceable, build platforms utilized in industrial additive manufacturing machines for the purpose of increased throughput.

3. Controller

On the 3D printer, a controller is a computer controlling various digital and analog equipment to work collaboratively to produce the part. The machine’s data is interpreted by the controller.

4. Extruder, Nozzle, Print Head, Hot End, Tips

These would be assemblies, usually associated with FDM and FFF, with conical heated tips where a raw filament stock is passed through, fused, extruded, and deposited on a print bed. The diameter of the nozzle depends on the layer height and bead thickness chosen. (For the record, FDM means fused deposition modeling, and FFF stands for fused filament fabrication)

5. Laser and Scanner

This creates an infrared or ultraviolet beam to harden a base material. IR lasers, usually CO2, are used to melt polymers or metals. On the other hand, UV lasers are used to cure photopolymer resins. Laser-based 3D printers may regulate the beam’s position and direction via mirrors and galvos or linear motion. A galvos laser scanning system is quicker but also more sophisticated and costly. Each system scans a 3D component for that layer in the rapid back and forth motions.

Depending on the material being scanned, a particular scanning method may be more appropriate than another. For instance, a selective laser melting system might monitor tiny islands of material to assist in controlling the accumulation of stress on individual layers.

6. DLP and UV Projector

In photopolymer printing, a digital light projector is employed. DLP 3D printers use a single cross-sectional picture of an item to cure a considerable area of the material. Undoubtedly, it is quicker than UV laser systems, which need rapid scanning to fix a layer. Carbon DLS builds isotropic features on 3D printed components by moving a DLP in the Z direction.

7. Build Chamber and Build Frame

Build chamber refers to an enclosed area wherein the part gets printed. Build bed, extruders, material feed, and laser & galvos systems are examples of its inclusion. A print begins with the part bed at its minimal state, with room for the part bed or linear extruder to move on the Z-axis.

8. Exchangeable/Interchangeable Frame

It is a detachable compartment for production AM. While the previous job is being processed, a new frame may be switched-in to print the following job. SLS, DMLS, and HP MJF all use this.

9. Electron Beam

To produce heat, electrons are accelerated and focused in a narrow beam. Metal 3D printing uses electron beam melting (EBM), and unlike lasers, varying magnetic fields may control electron beams, eliminating the need for galvos or linear motion systems.

10. Material Feed and Hopper

Material feed and hopper refer to the material supply source for component and support structure. Extruders are needed for filament-based methods like FDM, whereas powder bed platforms employ calibrated material dose. Material is supplied into powder bed systems such as SLS or DMLS by gravity or a vertical piston feed and recoater.

11. Overflow Bin and Material Overflow

A container called an overflow bin is used to store leftover material. Material jetting or filament systems may use this to keep discarded material. In contrast, the material is commonly recycled or reused for powder bed and photopolymer systems while storing it in a controlled environment.

12. Data Input

The interface stage is where layers, machine controls, and other data are fed into the controller. Data is frequently produced on a different computer and sent via USB, Wi-Fi, Ethernet, or serial.

13. Linear Motion Control

It is a part of the machine frame controlled by a pulley, belt, servo, screw, or actuator that moves the features of the 3D printer on the X, Y, or Z-axis. Some printers move the print head in X and Y directions while moving the build bed in Z. A linear control may be used to deposit material in the build platform or remove surplus material to overflow bins.

14. Support Structure/Material

The support structure is a material used to bind a part to the build area and establish a framework to weld or deposit material on when accomplishing overhanging portions in 3D printing.

15. Bed Leveler and Bed Leveling

Bed leveling is a standard feature on desktop printers that automatically measures the travel distance between the print head and the build platform. The system then adjusts for minor changes in the printing plane that might create irregular or unsuccessful prints.

16. Material Jet

A material jet is a depositing head that moves in a linear manner, similar to an inkjet, and positions micro-droplets of the material. The deposited material can be used to create the object directly, add color or reactive chemicals, or bind powdered material together before subsequent processing.

17. Print, Part, Object, Workpiece

The finished part, print, object, or workpiece is the 3D printer’s tangible product. In contrast, a sacrificial support structure can also be printed on the build platform.

18. Recoater and Roller

Recoater or roller is a mechanical blade or cylinder that pushes material from one end of the construction chamber to the other, dumping surplus into overflow bins. Powder bed systems such as SLS, DMLS, and HP MJF frequently fail due to component features bending upward into the recoater’s path, becoming stuck and dragged over the print area.

19. Build Plate/Sheet/Surface

The build surface is a part of the build bed that can be swapped out to reset the 3D printer for a new print. As the initial layer of the build material, build plates and sheets are vital for 3D printers that require a support structure. Part faults are also caused by poor bonding at the build plate.

20. Build Setup Software

A unique build setup software prepares a mesh file for 3D printing. STL files may be automatically fixed by mending mesh gaps and reversing or breaking features. Otherwise called “watertight” files, printable files have a continuous mesh geometry over their surface. This program can position the item on a virtual build platform, create supports, adjust infills, and simulate building. Before printing, the build simulation can assist with estimating timing and discovering difficulties.

Multiple pieces may be built on one build platform before being transferred as data for the 3D printer to read. The layer-specific information obtained by simulating and exporting the build is sometimes referred to as “slicing.” The most popular commercial build setup software is Materialise Magics, which can be utilized for various professional platforms. Custom support generation and optimum build nesting for powder bed platforms may be added to each platform.

How to Get Started with 3D Printing?

Let’s have a look at some considerations before you get started with 3D printing.

Preferred File Type

Most CAD files are in STEP. Most CAD and CAM applications allow Parasolid formats like STEP. Unlike mesh formats like STL and OBJ, Parasolids store unit information and other features. Native exports from tools like Solidworks can also assist services exploring the parametric feature tree with resolving model issues that may influence the print.

STL & Mesh Exports

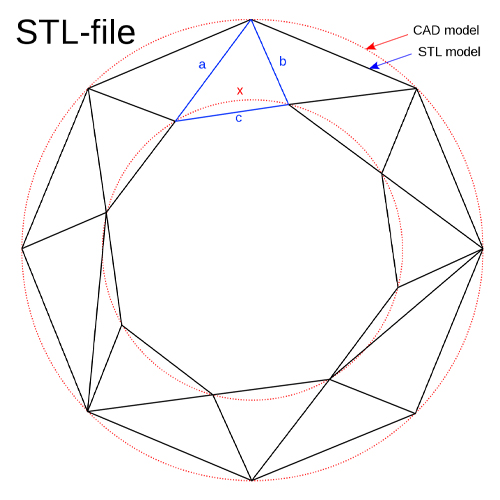

The 3D printer build setup software requires a mesh file, such as an STL or OBJ. Parasolid CAD files may be converted to STL files, and STL files can’t be converted back to parametric CAD. Creating STL files at a resolution that matches the 3D printing process while keeping file size down is crucial. Note that STL files maintain mesh surface data in the form of triangle series.

Curved surface tessellation reduces feature detail in mesh exports, which makes inverting an STL to a Parasolid difficult or impossible. STL files contain just exterior mesh geometry and no additional component information. Because most 3D printers read files in millimeters (mm), it’s critical to output in millimeters. If not, the uploaded file may be read differently.

To export an STL in SolidWorks, toggle Deviation, and Angle. If you want to yield the best results, you should choose Custom and shift each bar roughly 80% to the right.