Lathe refers to a versatile and fundamental machine tool used to perform various machining operations in any mechanical industry. With its diverse purposes and advanced forms related to computer numerical computing systems, the most straightforward procedure carried out using a lathe is removing excess material from the workpiece. The lathe is applied or associated with the tool, rotated to perform a particular operation, and get the desired size/shape.

The lathe machine can perform operations like tapping, turning, spiral cutting, forming, cutting, boring, passivation, and finishing & polishing. Thus, the main functionality of the Lathe machine belongs to remove material from the surface of the metal to form turned components with desired shape and size. Along similar lines, the workpiece is rotated against the tool. Likewise, the speed and direction of the tool by which it moves along the workpiece are called the feed.

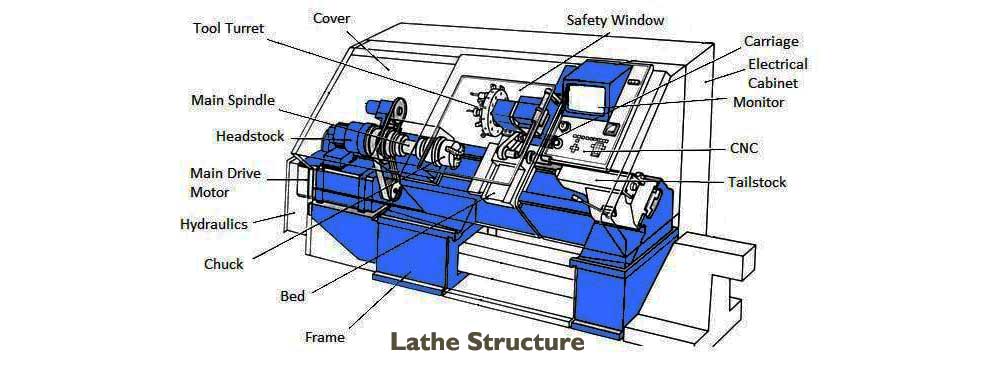

Main Lathe Machine Parts

Lathe machine has different parts, and the following are the details of these lathe parts:

Headstock

The headstock is a part of a lathe machine equipped with other essential lathe components such as gear speed control levers, chucks, spindles, and feed controllers. On the lathe machine, the headstock is located on the left side. It is considered one of the fundamental lathe machine parts.

Tailstock

The tailstock is also known as a foot stock. Without question, it has become an essential part of the lathe machine. Generally speaking, the tailstock is used to secure the work holding accessories and provide the workpiece with support in different operations. At the same time, tailstock can also be used as a cutting tool to perform standard hole-making functions.

Bed

The bed can be a foundation of all other turning parts associated with the lathe machine. In simple words, it is a foundation with which other lathe components such as carriage rails, headstock, and tailstock are bolted or attached.

Carriage

Carriage is between the tailstock and headstock as a foundation to many other lathe components such as saddle, apron, cross slide, tool post, and compound rest.

Lead Screw

Lead screw plays a vital role in getting your desired threading operation done. Essentially, it is used to move the carriage automatically while performing the threading.

Feed Rod

Feed rods offer a much similar operation to a lead screw. It makes possible the left to right and right to left movement of the carriage.

Chip Pan

Chip pan collects the chips of metal produced during the cutting process on the lathe machine.

Handwheel

The handwheel is used to slide different turning components such as tailstock, cross slide, carriage, and other elements associated with the lathe machine.

Simultaneously, as far as types of lathe machine are concerned, it is commonly divided into three types: Turret Lathe, Special Purpose Lathe, and Engine Lathe.

The Function of CNC Lathe

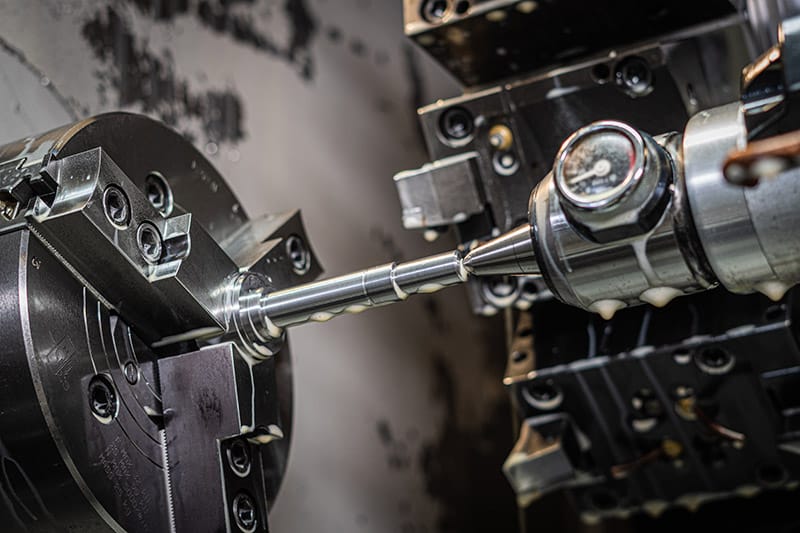

Compared with manual lathe machines, the CNC lathe and turning machines offer much better precision and efficiency. Meanwhile, the CNC lathe machine can perform various operations, which are certainly not possible with the simple lathe machine. The presence of a multi-station turret or power turret allows the CNC lathe machines to process oblique cylinders, linear cylinders, worms, grooves, and complex workpieces.

Technically speaking, the CNC lathe machines are equipped to settle the workpiece in a position defined by the pre-programmed processing programs. The code and program of the CNC lathe machine allow the operator to add all the parameters before starting the operation on the workpiece. Whether it is about the processing route, tool motion trajectory, cutting parameters, or setting of auxiliary functions, the whole format is fed into the processing list. It is then connected to the control medium. After providing all the information to the processing list, the cnc machine is ready to read instructions from the program and act accordingly on the workpiece.

Consequently, the whole process that includes the analysis of part drawing and the preparation of the control medium is referred to as the compilation of the NC program. In the interim, the most significant difference between CNC lathe and conventional lathe is the automaticity of all functions that need to be executed manually in a traditional lathe machine. We can process various lathe machine parts by changing the program and controlling the machine tool’s activity. In this way, the CNC machine tool is especially appropriate for handling and processing small batches of parts with intricate shapes and high precision prerequisites.

The CNC machine tool should deal with the lathe parts as per the program. Therefore, the programmer will enter the program into the CNC machine to command the tool to operate. Remember, the input of the program gets done through the control medium.

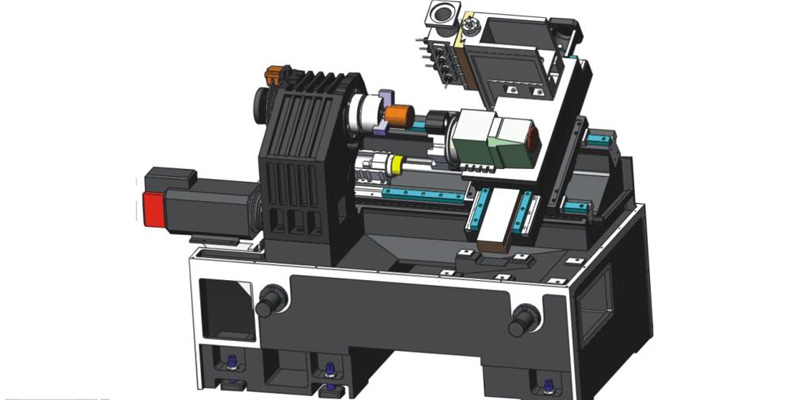

Structure of CNC Lathe Machine

CNC lathe machine possesses similar parts as the conventional lathe machine. Nevertheless, it has additional lathe components such as a cooling system, chip conveyor, and lubrication system to offer more precision and efficiency.

Typically, there are two types of CNC lathe machine: Vertical CNC lathe machine and Horizontal CNC lathe machine. The vertical CNC lathe machine is usually recommended for turning disk parts whose diameter is large enough. On the other hand, horizontal CNC lathe machines are preferred for machining parts with small discs or long axial dimensions.

Considering the applications and functions of horizontal turning machines, they can be further divided into ordinary CNC lathes, economical CNC lathes, and turning machine centers:

Economical CNC Lathe

The economical CNC lathe machine is formed using the turning feed system. Indeed, it is an ordinary lathe machine, which is then equipped with a single-chip computer and a stepping motor. Although this CNC lathe machine is lower in cost, its degree of automation and functionality is relatively poor, and the turning precision is usually not enough.

Ordinary CNC Lathe

The ordinary CNC machine is designed considering the requirements of the turning process and has a generalized CNC system. An ordinary CNC turning machine is perfect for turning standard rotary parts. It offers a comparatively better degree of automation, machining precision, and functionality. Besides, it can control the x-axis and z-axis simultaneously.

Turning Machining Center

The turning machining center is similar to the ordinary CNC machine but with a powerhead and additional operational axis. With the addition of one more working c-axis and milling powerhead, the turning machining center can also perform axial milling, radial milling, and surface milling, along with drilling and processing the holes.

Hydraulic Chuck & Hydraulic Tailstock

Hydraulic chucks remain functional when it comes to holding workpieces during turning on CNC. Moreover, special chucks are also used for the parts whose clamping part does not possess a cylindrical shape. Other than that, for processing features with a more significant axial-to-radial ratio, a live center supports the other end of the workpiece to ensure suitable processing. For the record, this liver center is mounted on the hydraulic tailstock.

CNC Lathe Tool Holder

Mainly, there are two types of tool holders of lathe machines:

- Special Tool Holders are usually used for specialized operations developed by the lathe manufacturer for the particular tool post. Even though such a tool holder yields lower costs, it misses the element of versatility.

- General Tool Holders are manufactured considering specific generalized standards enshrined by German Engineering Association and VDI. CNC lathe manufacturers can configure as indicated by the practical requirements of CNC lathes.

Milling Powerhead

Once after installing the milling powerhead on the tool post of the CNC turning machine, the processing capacity of the CNC lathe machine becomes massively improved. For example, the milling powerhead is introduced to ease the milling process of axial grooves and axial drilling.

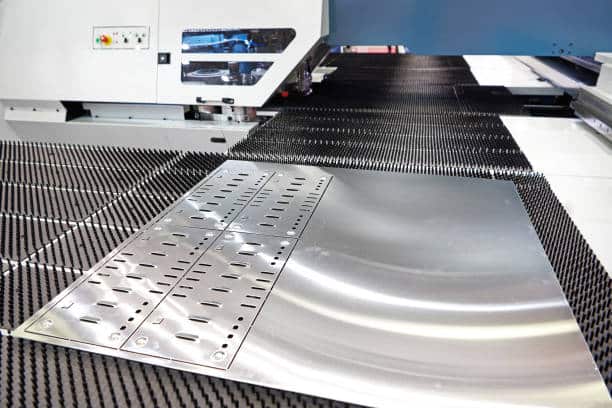

CNC Lathe Tools

It is crucial for CNC lathe machines or turning machining centers to design and position the tool while considering the tool holder’s structure and the number of tools to be installed. Furthermore, it is also recommended that the tool holder’s design be flexible to support a wide variety of tools. That is how not only will the expense be reduced, but it will also save time.

Runsom – Custom CNC Turned Parts Supplier

Now, you may have a basic knowledge of the structure, function, and main machine parts of a lathe. Then, you may need to look for a trustable and reliable supplier to manufacture your components with their CNC lathe machines. If you have this demand, Runsom Precision is here to offer you top support with our team of qualified engineers and machinists who well know the lathe configurations.

Our CNC machine shop has equipped with full sets of CNC lathe machines to satisfy a vast range of manufacturing demands. Work with Runsom, you can experience the incredible CNC lathe services and receive high-quality turned metal or plastic components for rapid prototyping or small-to-large volume production. Start your project with an instant quote.

Other Articles You May be Interested in: