Aluminum, a crucial material in engineering, finds extensive use across various industrial applications. Possessing a relatively soft nature, it can be easily cut using an assortment of tools. To ensure efficient and safe cutting of aluminum sheet metal, one must consider the appropriate tools for the task and various factors that influence the cutting process.

Follow this guide to discover the correct technique for cutting aluminum sheets and explore commonly used tools in this process.

Tools for Aluminum Sheet Cutting

There are several methods available for cutting aluminum sheet metal, ranging from manual tools to advanced industrial systems. In this section, we will explore the most commonly used types of tools for aluminum sheet cutting. When deciding which one to employ, it’s important to consider factors such as speed, accuracy, flexibility, finish, automation, and cost.

Hand Tools

Tin snips

The most commonly used tool for cutting aluminum is tin snips, also known as metal shears. These are ideal for small, time-sensitive aluminum projects that require quick trimming. Shears are the perfect choice for such situations as they do not generate heat during the cutting process. They can easily be maneuvered into tight spots to make hard-to-reach cuts, and they do not require any power source, allowing for convenient portability and versatility in cutting various materials.

Hacksaw

When it comes to cutting smaller pieces of aluminum, a hacksaw proves to be a useful tool. It’s not only suitable for cutting aluminum pipes and bars but also effective for obtaining shorter lengths of aluminum sheets. In case the default blades do not meet your requirements or wear down rapidly, there are alternative blades available that can be utilized for this purpose.

Hand shear

A hand shear is a tool equipped with a round cutting blade and snip. It is particularly useful for maneuvering into tight corners and produces a clean edge, surpassing other hand tools in this regard. However, it may still require some cleaning after use.

Chisel and hammer

Using a hammer and chisel to cut aluminum sheet metal is a relatively easy process. Align the edge of the chisel with the desired cutting line and strike it with a hammer. To preserve the chisel’s tip and facilitate the cutting process, it’s advisable to place a softer material, such as wood, as a support behind the metal. This method involves progressively cutting through the metal similar to using a can opener. While this approach is suitable for small garage projects, note that it is a slow and labor-intensive process. In addition, the resulting edge quality is likely to be poor, necessitating the use of a file to smoothen and make it safe for handling.

Bench Tools

Band saw

For most thicknesses of aluminum up to 1/4″, a carbide-tipped or standard steel blade is usually sufficient. However, when dealing with heavier gauges, it’s advisable to proceed at a slower pace. Placing a piece of particle board or plywood beneath the sheet metal is said to aid in the cutting process. This technique helps to dissipate the heat absorbed by the aluminum. Additionally, applying masking tape on top of the metal can be beneficial. To ensure smooth cutting, various cutting oils and waxes are available that assist in keeping the metal cool while allowing the teeth of the blade to cut efficiently.

Circular saw

Circular saws are readily accessible and user-friendly tools. They are effective for making straight cuts on sheet metal, particularly when equipped with specialized sheet metal cutting blades. While not the optimal choice for thicker sections, circular saws excel at quick cuts and smaller areas. For precise cuts on aluminum, especially in preparation for intricate tasks, both circular saws and miter saws are excellent options.

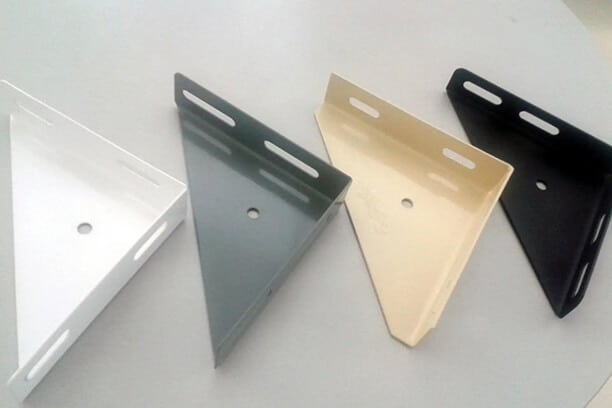

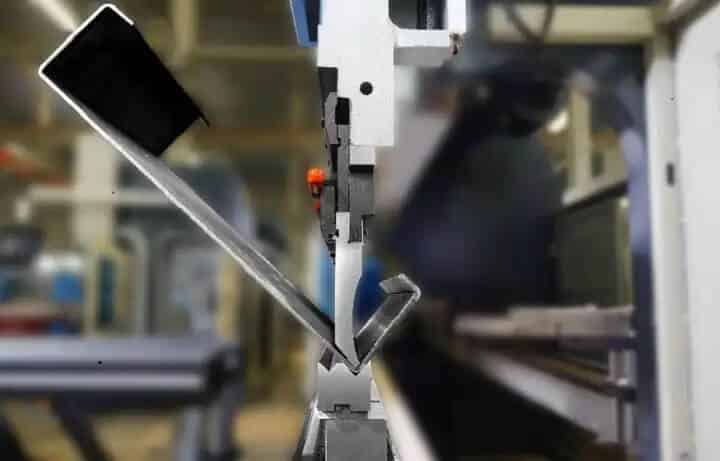

Metal brake

Metal brakes are tailored for cutting metal in a distinct manner when compared to power tools. Instead of employing a cutting action, metal brakes utilize a bending motion to flex and score the metal, leading to a precise break along a straight line. Despite their large size and potential for being somewhat cumbersome, metal brakes excel in effectively cutting lengthy and straight sections of aluminum sheet metal.

Bench mounted shears

Bench-mounted shears can cut through comparatively thick aluminum sheets, but their design typically restricts the cuts to straight lines. These shears are particularly suitable for hobbyists and sheet metal shops engaged in custom or repair work. The majority of these machines are durably constructed and can withstand the test of time, provided that the blades are regularly maintained in a clean and sharp condition.

Stationary nibbler

It’s designed for nibbling operations, capable of cutting various profiles within its throat. However, note that this tool requires a wide kerf and leaves behind a serrated edge. During the aluminum cutting process, it’s essential to be aware of the chips that are ejected by these machines, as they can accumulate and pose a safety hazard.

Beverly throatless shears

A widely used type of throatless shear, known for one of its major manufacturers – Beverly, is popular among small sheet metal shops due to its versatility and dependability. By appropriately adjusting the spacing between the cutting edge and the back plate, you can achieve a neatly rounded edge that may not need further cleaning. These shears are available in three sizes, namely B1, B2, and B3, based on the desired size and power requirements.

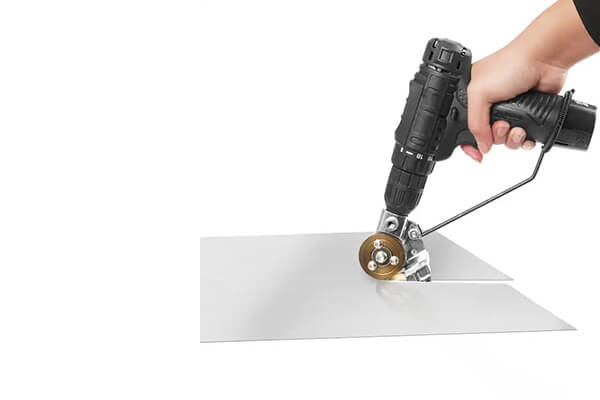

Power Tools

Electric jigsaw

Handheld jigsaws offer a range of outcomes for aluminum cutting. With the appropriate tool and the right bit or blade, you can easily cut through thick sheets and other types of stock. However, using the wrong saw and blade can result in damage to both the workpiece and the tool itself.

Power shears

Handheld micro shears are highly efficient when it comes to cutting aluminum sheet metal due to their maneuverability. Unlike angle grinders, they generate significantly less heat, alleviating concerns of metal melting. However, power shears may produce undesirable noise and sheet vibration, and may not provide the desired edge quality. If you are unable to secure the workpiece using clamps, it’s crucial to have a good understanding of how the tool will move and interact with the sheet.

Angle grinders

Cutting aluminum using grinding devices can pose significant challenges. Due to its ability to absorb heat energy and its low melting point, the metal has the tendency to melt and solidify around the blade while in use, resulting in hazardous binding. Therefore, it’s crucial to approach aluminum cutting with the intention of removing the metal rather than grinding it away.

Industrial Cutting

Waterjet cutter

The water jet machine is highly regarded for cutting intricate or thick aluminum. It involves directing an incredibly thin stream of water, mixed with abrasives, at extremely high pressures and speeds onto the sheet metal. This focused water jet effectively erodes the metal, leaving behind a clean and smooth edge. Since the water jet does not melt the metal like laser systems do, heat dissipation is not a concern, making the energy required to cut steel or aluminum relatively similar. Remarkably, water jet cutters are capable of cutting through very thick sheet metal with great precision, even up to a few inches thick. The notable advantages of water jets lie in the quality of the finished edges, the ability to work with various materials, and their accuracy. However, water jet cutting can be expensive and time-consuming.

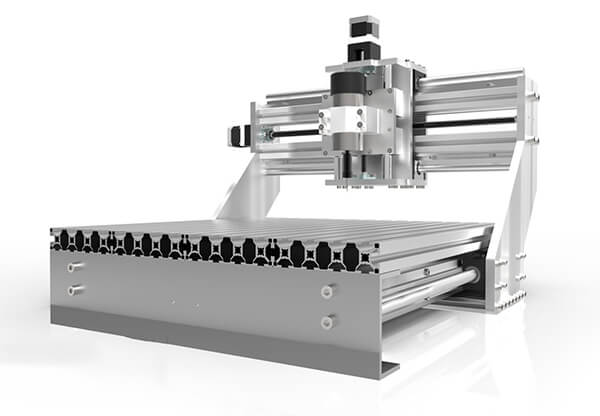

CNC machine

The aforementioned tools are most effective for cutting aluminum sheet metal or bar stock into smaller, more manageable pieces. For more intricate tasks, high-speed CNC machine tools offer excellent options. CNC lathes and mills are particularly useful for shaping thick aluminum components into finished parts, and they’re also ideal for producing large batches of identical parts in a production run.

Laser cutter

With regards to cutting light to medium gauges of aluminum, modern lasers can be quite effective. Due to the higher heat absorption of aluminum compared to steel, industrial lasers require a significant amount of power to heat the aluminum and allow the gas to blow through. Fortunately, modern equipment can achieve this, enabling the cutting of aluminum plates up to 1/2″ thick. However, the challenge remains in managing heat dissipation, as is often the case. For more detailed information on laser cutting, please refer to our post on the topic.

CNC router

CNC routers can not only cut soft materials such as wood, plastic, acrylic, and leather, as well as hard materials like metal, including aluminum, copper, and stainless steel. By selecting the appropriate spindle head and feed speed, aluminum sheet cutting can be easily achieved. Aluminum with a thickness of 5mm can be cut with a CNC router, but not 10mm. It’s recommended to use a single-flute specialized aluminum end mill for cutting aluminum when using a CNC router to cut aluminum sheets, offering non-sticky cutting, high speed, and high efficiency in the machining process.

Punch press

Punch presses utilize specialized tools to create various shapes in sheet metal. With larger presses, it’s possible to load multiple types of tools for specific cutting and forming purposes. While they may not be as fast as lasers, punch presses offer the advantage of being able to stamp, roll, and form the metal during the cutting process. This enables the creation of louvers, jogs, beads, and impressions that lasers are unable to achieve. Additionally, punch presses generally have a lower initial cost compared to lasers. However, there are maintenance costs associated with the tooling.

Step-by-Step Guide for Cutting Aluminum Sheet

To ensure a safe and precise cutting process for aluminum sheets, follow the following steps:

Step 1: Measure Sizes and Mark Cuts

To begin, employ a measuring tape to determine the dimensions of your aluminum sheet in terms of length and width. Then, utilize a straight edge or ruler to generate a line across the sheet, denoting the location where you intend to perform your cut. Ensure that the line is visibly marked with a pencil or marker, guaranteeing precision throughout the process.

Step 2: Secure the Aluminum Sheet

To ensure stability and hazard-free operation while cutting, use clamps or a vice grip to firmly secure the sheet in place. This precautionary measure not only prevents the sheet from moving but also enhances safety throughout the cutting process.

Step 3: Wear Protective Gear

Before starting cutting, remember to wear safety goggles and gloves as a precautionary measure. These protective gears will shield you from potential harm caused by flying debris and sharp edges.

Step 4: Use the Right Cutting Tool

When it comes to cutting aluminum sheets, there are various cutting tools available for your selection, such as jigsaws and circular saws equipped with metal-cutting blades. Choose the tool that best fits your specific project requirements.

Step 5: Start Cutting

Start along the indicated line to cut while closely adhering to the straight edge or ruler. Maintain a deliberate and slow motion to prevent any deformation or distortion of the sheet. Keep your hands a safe distance away from the blade at all times and verify that the saw is operating at optimal speed prior to making contact with the sheet.

Step 6: Finish the Cut

After successfully cutting through the sheet, deactivate the saw and wait for the blade to halt completely before removing it from the sheet. Employ a metal file or sandpaper to eliminate any rough edges and achieve a smooth finish.

Tips for Cutting Aluminum Sheet Properly

To ensure optimal outcomes when cutting aluminum sheets, consider the following factors:

Choose the Correct Tool

When working with aluminum sheets, it’s vital to select an appropriate tool due to their thin and lightweight nature. The ideal tool should possess adequate power to cut through the sheet effectively without causing damage or warping to the material. Generally, opting for smaller diameter blades is preferred as they tend to yield cleaner and more precise cuts. This is because smaller blades result in less runout, which in turn leads to smoother cuts.

Put on PPE

Ensuring personal safety during the cutting process generally entails wearing safety goggles and clothing that fits close to the body. Avoid loose clothing and gloves that could potentially become entangled with the moving blade if the user gets too close. Similarly, remove any rings or jewelry that may pose a risk of catching on the blade. Exercise caution when dealing with cut edges, as stray fabric remnants can be sharp and potentially cause injury to your fingers.

Use A Fine Blade

When working on metal cutting, it’s crucial to choose a wood blade with a fine tooth count. Additionally, ensure that the blade is adequately lubricated with oil and allow it to cool slightly between cuts. Employing these measures reduces the risk of harm and helps maintain the integrity of the material being cut.

Secure the Workpiece

Achieving both accuracy and safety is paramount when cutting aluminum sheets. One valuable approach is to prioritize the use of clamps and guides whenever feasible. Clamps effectively secure the aluminum sheet in position, allowing for precise, guided saw movement along straight lines or curves as required. This approach significantly reduces the likelihood of accidents caused by slipping or shifting during cutting. Moreover, clamps and guides streamline the process, making it simpler to attain accurate results with less exertion.

Use Cutting Oil

Another crucial component of cutting aluminum is the use of cutting oil. The main risk is that the material will catch or get caught in the saw, which could lead to splinters. If that occurs, it is possible that anyone nearby will be struck by the shrapnel created by the blade or aluminum splintering off quickly. Before working on the aluminum workpiece, strongly advise clamping it.

To mitigate the risk of blade clogging or aluminum catching, it’s crucial to lubricate the blade with a low viscosity cutting oil. This lubrication serves multiple purposes, including keeping the blade and aluminum cooler, reducing the likelihood of splintering, and preventing overheating.

Conclusion

The article offers a detailed guide on common tools for cutting aluminum sheets, along with guidelines for ensuring safety and efficiency in the cutting process. Furthermore, it presents a step-by-step guide and valuable tips for achieving optimal results when cutting aluminum sheets.

Your CNC Aluminum Machining Solution – Runsom Precision

There is a diverse selection of tools and techniques available for the aluminum cutting process. One such method is CNC aluminum machining, which utilizes computer-controlled cutting to shape aluminum materials in various forms such as bars, sheets, or plates. Runsom Precision has been a CNC machining expert in manufacturing custom precision aluminum parts for more than a decade. Our advanced CNC machine shop is well-equipped with the latest equipment to fit the specific requirements of your project. Furthermore, we provide sheet metal fabrication services for aluminum, steel, stainless steel, copper, etc. Work with us starting with an instant quote today!

Other Articles You May Be Interested in: