Precision Micromachining Services

Offering miniature machined parts in consistent quality and ultimate precision with our micromachining services

Fast turnaround and instant pricing on your micromachining projects

Build custom-designed solutions to save your time and money

Runsom Precision is backed by our ultra-precision micromachining techniques as well as highly specialized machines in this area, providing top support for global customers to create intricate micro components that exactly fit their requirements.

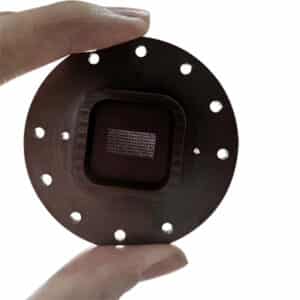

With the development of telecommunications, the Internet, and computer capabilities, the demand for micromachining services is becoming increasingly prevalent in an array of industries worldwide, especially in the technology area. If devices aren't shrinking in size, so are the parts that make them work for greater efficiency and better performance.

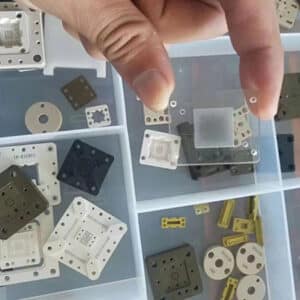

Nowadays, micro components can be seen and have been already applied in every aspect of our life, like miniature machined parts for the latest mobile phones, computers, music devices, etc. There is an inevitable tendency for manufacturing companies to enhance their capabilities in precision micromachining to catch up with the advancements of modern technology most notably in the field of satellite, medical, and electronics industries.

What Is Micromachining?

Micromachining was as a technology developed in the late 1990s to meet the growing demand for smaller, more complex parts in the semiconductor and medical industries. To this end, precision engineers began to develop techniques for machining tinier parts with smaller tools, mainly through trials and errors. Machinists at Runsom Precision have been dedicated to this field for a long time and make a difference in the R&D of certain core technologies with their highly professional micromachining experience.

Advantages of Precision Micromachining

Micromachining is ideal for ultra-precision components, and Runsom Precision has access to deliver what you just want with our precision CNC micromachining services. Our micromachining specialists are crucial in various industries including: Optical, Medical, Aerospace, Tool & Die, Pharmaceutical, and more.

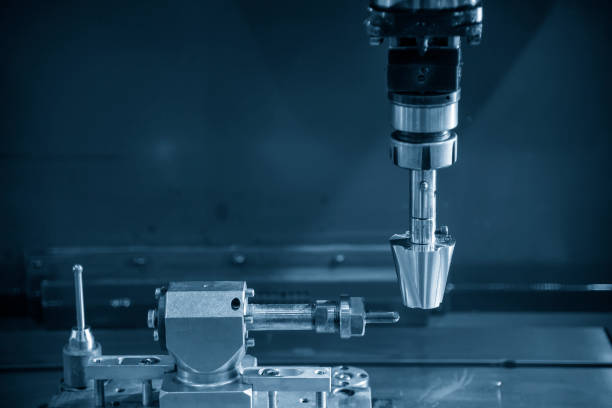

The highly specialized machines and tools used in the micromachining process enable the fabrication of precision components tiny and intricate enough along with tight tolerances in a repeatable production run.

Micromachining provides a method of machining smaller parts in a single operation, so milling and turning can be completed on the same machine, helping speed up turnaround and enable more efficient machining of parts.

Prototypes and parts requiring micro features can depend on micromachining techniques to realize their desired functions, fulfilling a multitude of applications.

Micromachining takes machines with high spindle speeds or Swiss-type lathes to realize cleaner cuts to create parts with tighter tolerances and more precise dimensions used most frequently in specialized applications like the medical and semiconductor industries.

Implementing micromachining in your precision engineering practice provides you with more diversified and precision parts to undertake a wider range of bids.

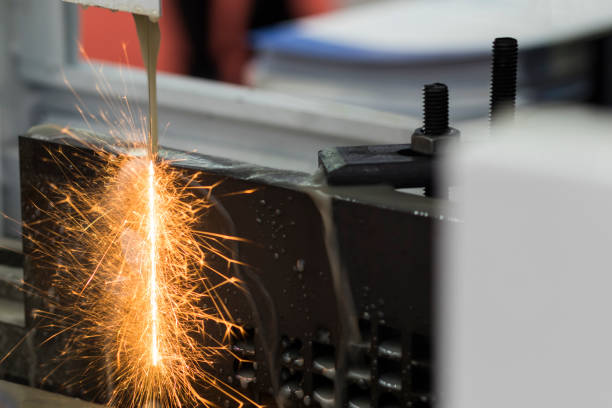

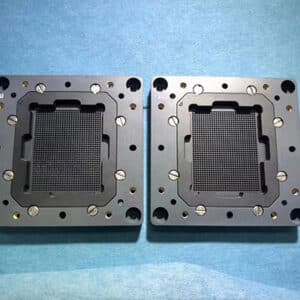

EDM Micromachining

Sink/Plunge EDM machines equipped in our machine shop are custom-designed to produce the finest plunge patterns.

Runsom Precision is always ready to offer you solutions to your precision micromachining needs for full production or just prototyping for any parts or assemblies. Our miniature products have been widely used in various industries, showing the excellent flexibility and capability we own to satisfy the needs of our customers.

If you're stuck with complex parts for your critical application, choose our micromachining services. So, request a rapid quote right now!

CNC Swiss machining is a perfect method for manufacturing the tiniest components with the tightest tolerances. Our Swiss CNC lathes perform exceptional cutting and drilling features close to the millimeter. These machines are the preferred choice for machining extremely precise and detailed workpieces with 8 axes of motion, 2 independent tool systems, and a flexible machining area. This technology enables us to produce any component with paramount machining features such as detailed intricacies for any industry.

Products made from CNC Swiss lathes can fit every crucial specification and detail, and Runsom Precision has access to deliver what you just want with our precision CNC micromachining services.

If you need Swiss machined components requiring quality, precision, and efficiency, our best CNC experts are delighted to work with you to craft the best CNC precision parts in accordance with specific requirements. So, request a rapid quote right now!

Get A Quote to Build Your Micromachining Project Now

Runsom Precision is capable of utilizing precision micromachining technologies including 5-axis milling, CNC Swiss machining, and Wire EDM Cutting to fabricate your components with ultimate precision. If you cannot find a suitable machine shop to process your complex parts, approaching Runsom Precision is the way to go. Machinists with a high level of experience and CNC machines with incredible efficiency allow us to build components with near-impossible specifications that other machine shops are hard to reach.

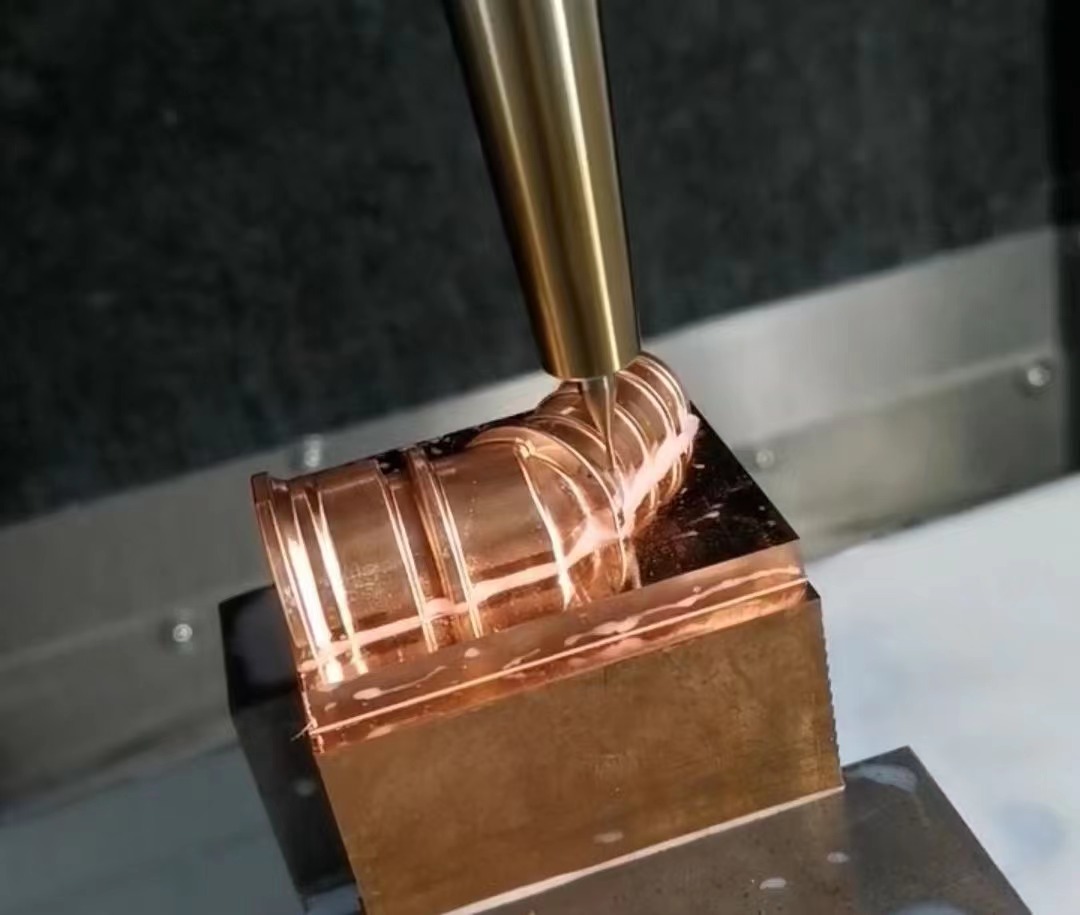

Runsom Precision creates more possibilities with our 5-axis machining technology while most machine shops still provide their clients with 3 or 4-axis milling services. Our precision 5-axis milling centers are crafted by CNC machinery artisans in Germany and Switzerland, which have already exclusively calibrated to reach the highest precision effects.

To further enhance the performance of our milling equipment, our facilities are temperature and dust controlled. We have a full awareness of assurance of consistent quality and accuracy on precision components determined by complete control over all machining factors. Thus, we carefully calculate and execute all elements, like the effects of vibration of micro-drilling and handling of parts, and fluids in micro-cutting that may occur in the micromachining process, to build a defect-free micromachining environment for the best-finished results.

Precision Micromachining FAQs

Micromachining promotes the limits of size and precision. With extremely precise tools, strict tolerances, and machines specialized in this field, it is possible to create complicated miniature components, especially those used in the aerospace, medical, pharmaceutical, and electronics industries.

Micromachining is the process of making miniature parts with tools with a diameter of less than 0.015 inch, and a tolerance of only a few tenths. During processing, it requires a machine with sufficient spindle speed and durable cutting tools to run repeatably and stably at a high speed. The diameter of the micromachining tool can be as small as 0.001 inch (1/3 of the diameter of human hairs) to achieve the required accuracy and detail. Thus, it can create very small and complex parts for certain applications, especially in the semiconductor and medical industries.

Laser micromachining is a multi-functional process, which is widely used to process metal, plastics, and glass, and to prepare thin foils. The process includes different mechanisms such as drilling, cutting, turning, threading, marking, etc.

Micromachining is often employed to manufacture components of medical, miniature sensors, electronic, and optical devices. Common engineering materials for these applications include aluminum, titanium, copper, stainless steel, and tool steel for miniature molds and dies.

Bulk micromachining is a process applied to form Micro Electro Mechanical Systems (MEMS). It creates structures inside the substrate through selective etching. Micromachining is often used on silicon to remove pieces from the solid material until the desired shape is achieved.

Surface micromachining adds thin film layers (usually about 5 or 6 layers) to a substrate to create micro-scale structures. Therefore, surface micromachining is ideal for creating sensors and circuits and can create up to 100 layers of products.

Micromachining is very popular among a multitude of industries, including aerospace, military, optical, medical, pharmaceutical, aviation, and so on. It is also a cost-effective technique to fabricate miniaturized parts efficiently and quickly.