Locks with interchangeable cores provide an added level of security and convenience. Small Format Interchangeable Core (SFIC) locks are a popular choice for commercial buildings and institutions as they allow for quick and easy rekeying. The SFIC lock cores can be replaced in a matter of seconds, without the need for a locksmith. In this article, we will explore the various aspects of SFIC lock cores, including what they are, how they work, their structure, and how they differ from LFIC.

Why Use Interchangeable Cores?

Interchangeable cores are designed to simplify the process of keying and re-keying locks. Unlike traditional cores that require the removal of lock parts for installation or replacement, interchangeable cores offer interchangeability so they can be easily inserted or removed using a control key. The control key retracts a small piece of the core, such as a pin or bar, that holds it in place. Once the core is inserted, the control key is removed and the small piece is secured inside the housing. It is important to ensure that the housing is compatible with the small piece on the core.

What’s SFIC Lock Core?

The “IC” in this abbreviation stands for the interchangeable core which refers to a lock cylinder that can be adjusted to fit different keys. This mechanism uses a specialized control key to insert and remove the essential combination components. SFIC, that is, “Small Format Interchangeable Core”, is commonly recognized as a standard size by lock manufacturers while large format interchangeable cores (LFIC) are available in different sizes.

SFIC can be easily replaced while still in the lock set, which includes lever, knob, or deadbolt locks found on doors. These lock sets are designed to specifically accept SFIC lock cores, which can be interchangeable between different manufacturers. All SFIC lock sets are manufactured to meet these lock core standards and can be installed or removed using a “Control Key”.

How Do SFIC Lock Cores Work?

The core of SFIC locks can be efficiently replaced by using a control key, as the key operates and releases a retainer that secures the core inside the lock. The existing cores can be removed, and new ones can be inserted using the control key. SFIC core is an ideal choice for properties where rekeying is frequent, such as offices, universities, dormitories, and others, as it enables the rekeying of multiple locks quickly.

Main Part of A SFIC Lock Core

SFIC lock cylinders are available in both six and seven pin versions and can utilize the same keys for both. The keys for six pin locks stick out of the keyway a bit further due to being “tip stopped”. There are typically around 25 different keyways used. The lock in the picture below is designed for the “L” keyway. The pins used in SFIC lock cores are slightly smaller compared to those used in conventional cylinders and have tighter tolerances. These locks support various depth systems, allowing for up to 10 distinct bitting heights per pin position with no MACS restriction. Consequently, each keyway can have up to 10,000,000 unique keys, although in practice, there are fewer as a result of tolerance errors and phantom keys in master systems.

1. Control Key

The control key, which is cut from the same blank and appears identical to a regular key, is capable of turning approximately 20 degrees in a clockwise direction. This action disengages the retaining tab that secures the core in the housing, making it possible to remove or install the core within the lock housing. The housing stays fixed in the door while the core is extracted. (A standard-size screw-in mortise cylinder is illustrated in the picture below.)

2. Operating Key

The operating key is the key that is used to open and close the lock, which is often mastered. In the picture below, notice the two holes at the back of the plug that correspond with the fingers in the housing. Additionally, there is a retaining tab that runs halfway along the core’s length, which secures the core in the housing and stays locked when an operating key is used.

3. Housing

SFIC lock housings are equipped with two fingers that engage the core’s plug and are linked to the locking mechanism. These fingers extend approximately halfway down the length of the cylinder. Besides standard mortise cylinders, housings for SFIC are available for a variety of lock types, including electrical switches, rim cylinders, cabinet locks, key-in-knob locks, and padlocks.

4. Plug

The plug in SFIC lock cylinders (seen in the picture below ) is made up of two parts: an inner plug with two holes at the back that correspond with the housing fingers, and a control sleeve with a retaining tab. This configuration creates two separate shear lines. Operating keys align with pin stack cuts at the inner shear line, allowing the plug to rotate a full 360 degrees. Control keys align with pin stack cuts at the outer shear line, enabling the retaining tab to be retracted.

5. Keyway

The keyway on an SFIC lock core is the specific shape and size of the channel that runs through the core, where the key is inserted. SFIC keyways are standardized to conform to a specific industry standard, known as the “Best” keyway. There are several types of keyways for locks. To determine the keyway for your lock, you can refer to an existing key by inspecting the letter stamped at the bottom of the head of the key. The letter could be A, B, J, L, WA, WB, or others, helping you to identify the keyway required.

6. Hole

The holes located at the base of the control sleeve are designed for a punch tool to be inserted, which pushes the pin stacks out of the core’s top. This feature allows for cores to be emptied and re-pinned without disassembling the lock. (Corresponding holes are present at the bottom of the core’s shell. )

SFIC vs LFIC – Small Format vs Large Format Interchangeable Core

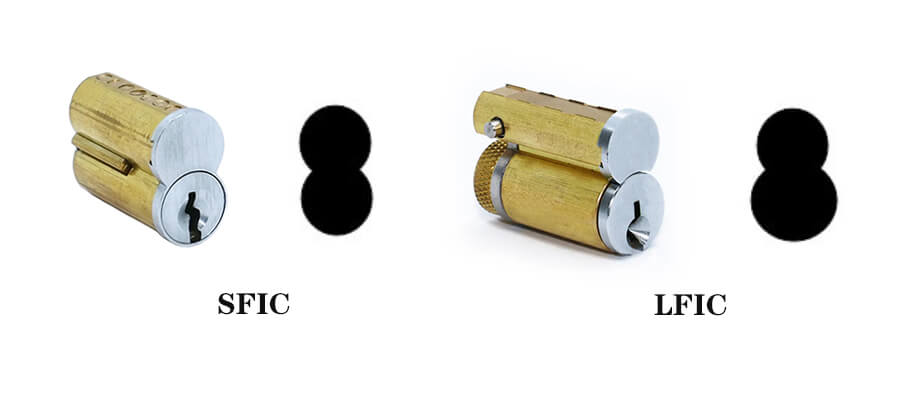

The Large Format Interchangeable Core (LFIC) is a type of interchangeable lock core used in high-security commercial applications, such as in government buildings, hospitals, or financial institutions. Although an LFIC lock cylinder is similar to an SFIC one, it differs in that the size and shape of the core differ across various brands. There are some key differences between SFLC and LFIC:

1. Size: The most obvious difference between SFIC and LFIC lock cores is their size. SFIC lock cylinders are smaller than LFIC lock cylinders, typically measuring around 1.125 inches in diameter, while LFIC lock cores measure around 1.75 inches in diameter.

2. Keyways: SFIC lock cores have a more standardized keyway, while LFIC can vary significantly between manufacturers. This means that LFIC cores may require specific keys or tools for installation and maintenance.

3. Face of core: The small format interchangeable core features concentric circles, while the large format interchangeable core has a larger bottom circle. The face of both cores is depicted in the picture below.

4. Installation: Both SFIC and LFIC cores can be installed in a similar manner, but LFIC may require larger and deeper holes to be drilled into the door, which can add complexity to the installation process.

5. Security: LFIC lock cylinders are generally considered to be more secure than SFIC due to their larger size and more complex keyways. However, SFIC cores can still provide reliable security and are commonly used in residential or low-security commercial applications.

6. Availability: SFIC lock cores are more commonly used than LFIC lock cores, especially in residential settings. This means that SFIC lock cores are typically easier to find and may be less expensive than LFIC lock cores, which are more commonly found in high-security commercial settings.

7. Compatibility: SFIC lock cores are not compatible with LFIC and vice versa, meaning that if you want to switch from one type to another, you will need to replace the entire lock cylinder and potentially the hardware as well.

In short, SFIC lock cylinders are smaller and more standardized, making them easier to find and install, but they may be less secure than LFIC. LFIC lock cylinders are larger and more complex, providing greater security, but they may be more difficult to find and install, and may require specific keys or tools.

Conclusion

SFIC locks are a popular choice in commercial buildings due to their ease of installation, maintenance, and high security. The article explains SFIC lock cores’ structure and highlights the differences between SFIC and LFIC lock cylinders in size, keyways, installation process, security, availability, and compatibility. Understanding these factors can help you choose the right type of lock cylinder for your specific application based on security and convenience needs.

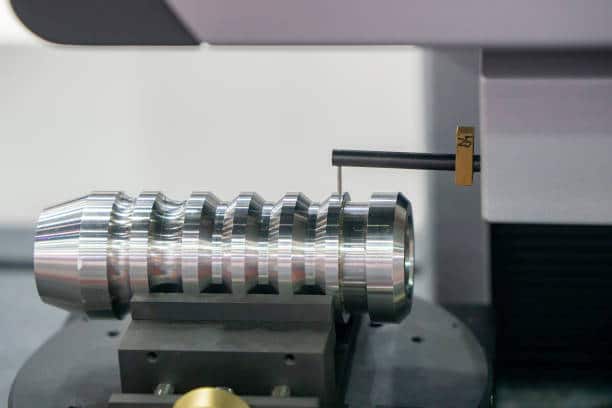

Custom CNC Machining Lock Cylinder Manufacturer – Runsom Precision

With the latest CNC machining technology, Runsom Precision offers a range of precision machined lock parts and accessories for the mechanical security industry. Our state-of-the-art CNC machining centers, exceptional manufacturing facilities, first-rate testing equipment, and expert engineers and technicians enable us to provide customized door lock cylinder manufacturing services that precisely meet the needs of our clients. Our manufacturing capabilities include CNC milling, turning, drilling, and finishing. Request an instant quote to get started with your custom lock cylinder parts manufacturing with our online CNC machining services.

Learn More About Our CNC Machining Lock Parts Services

Other Articles You May be Interested in: