China CNC Drilling Parts Machine Shop - Custom CNC Drilling Services

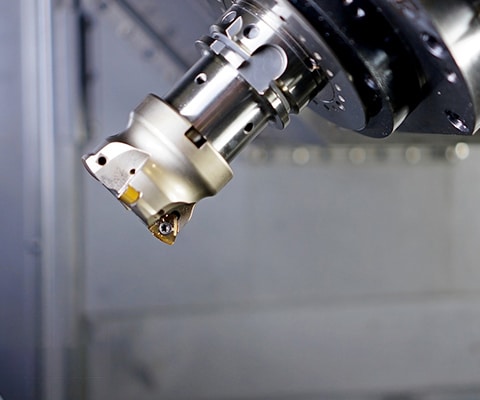

There is a role for computer numerical control (CNC) to play when it comes to precision and productivity for numerous applications across different industries. The precision CNC drilling technology makes it possible to drill holes or other shapes at desired sizes and dimensions to create a vast series of parts or components with high performance, reliability, and precision.

Runsom Precision has equipped with various types of high-precision CNC drilling machines including bench, radial, and vertical to support complete machining services. The integration of the latest machines and expert engineering team allows us to drill holes up to 7cm in diameter in simple and intricate geometries, and handle blind holes, small holes, angled holes, ball-end holes, concentric holes, and deep holes with guaranteed quality and precision.

Whether your parts are needed to be drilled in simple or complex patterns, we have the capability of machining of exact shapes you require to accommodate your requirements efficiently and effectively. We also offer a wide range of materials available for CNC drilling including metals, alloys, plastics, as well as polymers to perform your work in-house to meet your quality standards.

Before commencing drilling operations, it is of great significance to consider a facility’s capabilities carefully. Productivity, drill availability, thread formation, and material properties may vary widely in CNC drilling operations. The feasibility and efficiency of production also depend in large part on the level of expertise of machinists.

Drilling refers to a cutting process in which the tool is moved, the center of the tool is aligned with the center of the hole, and the tool is rotated without the workpiece moving. CNC drilling is mainly performed on CNC machines, including CNC mills and lathes. CNC drilling is typically used in the creation and modification of round holes, machine screws, and bolts. Drilling can process parts in hard plastics, metals, wood, and the majority of other rigid materials.

The main procedures of the CNC drilling process include:

1. CAD and CAM software translates the design schematics into computer code for use with CNC machines.

2. The computer or controller uses this code as an instruction to the machine when designated material is loaded into the drill press table or clamped in a press vice.

3. The operator initiates the drilling process through the control interface or panel.

4. A series of commands are executed in sequence to make holes or threads of accurate and precise spacing, depth, and diameter.

5. While the process is automated, trained machinists are expected to supervise the operation and perform regular maintenance on the computer system and the drill to ensure consistent accuracy and longevity of the product.

Types of CNC Drilling Machines

The following concludes with the main types of CNC drilling machinery.

This machine is a CNC drill with a geared spindle drive head that is primarily designed for large, heavy parts. Different from most other drills, it is universally known for feeding the workpiece into the cutting tool.

The basic mechanism employed by this type of CNC drilling machine is to set a moving spindle over a stationary workpiece. The wheel head offers cutting tools that can conduct a variety of operations on parts that come in different forms and sizes.

Gang drilling machines have many work heads. These heads are placed on a table where the parts are mounted or fixed. It speeds up the simultaneous machining of what would otherwise require an infinite number of consecutive operations.

As its name suggests, a multi-spindle drilling machine has several spindles connected to s single work head. These spindles are all fed into the workpiece at the same time. These machines are used to produce parts that require many closely spaced holes.

A micro drill press is a highly precise and small drilling machine with tiny chucks. It is usually used when handling and shaping small parts.

Turret drills possess many working heads mounted on a turret. This configuration allows quick changing of the required drilling or cutting tools and positioning over the workpiece.

Advantages of CNC Drilling

CNC machining is a manufacturing process in which computer software dictates the movement of machine tools and machinery. The process is used to control a variety of sophisticated equipment such as CNC drills, mills, lathes, and routers, offering numerous advantages over the manual method.

![]()

Precision

Parts made by a CNC drill machine have incredible precision and are widely used in numerous applications in need of high accuracy and precision, helping to optimize product performance, improve productivity, and lower costs.

![]()

Scalability

The ability of a CNC drill machine to accept multiple drill bits is a distinct advantage. Operators can equip a drilling machine with multiple drill bits for different usages and operations.

![]()

Uniformity

CNC drilling employs computer-automated machines to precisely drill threads or holes into surfaces of variable material composition and thickness leading to a consistent and defect-free output.

CNC Drilling Applications

A multitude of applications requires precision machined parts with consistency, complex dimension, accuracy, and tight tolerance to function and fit perfectly into their assembly as intended. With its great precision, efficiency, and versatility, CNC drilling is preferred by various industries to make quality products, such as lighting, construction, medical, agriculture, aerospace, military, automotive, and pharmaceuticals.

Across a wide range of industries, CNC drilling is commonly practiced in machine shops and mass production facilities to create and modify furniture, brush handles, boats, shoe lasts, golf clubs, and more.

These CNC machines create parts with ultimate accuracy, precise dimensions, and high efficiency. The quality and market delivery of OEM end products will be greatly promoted by using CNC machined and drilled parts.

This manufacturing technique effectively and fast produces precise holes or threads in a fraction of the time required by manual operations. It’s for this reason that some critical industries often utilize CNC machining to enhance efficiency and productivity while lowering costs, especially automotive, aerospace, military, medical, defense, and pharmaceuticals.

CNC Drilling Capabilities

1. CNC Drilling Machinery

Our CNC machine shop has equipped with CNC vertical machining centers and lathes, including CNC vertical machining centers, Swiss automatic lathes, and multiple spindle drills, allowing for the fabrication of parts in a wide range of raw materials, shapes, dimensions, and types.

2. A Variety of Spindle Drills

A full line of spindle drills confers our operators to the advantage of being able to produce components to our clients’ exacting drawings or specifications. Our incredible in-house CNC drilling capabilities include: sub spindle, active tooling, turning, threading, and drilling in multiple axes, and a 12-foot-long bar feed.

3. CNC Drilling Shapes

Runsom offers custom CNC machining and drilling services at a rapid turnaround and competitive price for global customers. We focus on drilling and manufacturing parts with complex shapes in tight tolerance. Available shapes are square, round, flat oval, teardrop, D-shape, rectangle, and custom shapes.

4. A Wide Range of Materials

Whether your application calls for soft or hard metals, Runsom has the keen expertise to provide high-quality custom metalworking and CNC drilling services. We manufacture parts in designated materials according to your designs. We work with aluminum, stainless steel, alloy steel, carbon steel, titanium, brass, as well as plastics.

CNC Drilling FAQs

A drill is a tool used to make round holes or drive fasteners. It houses a drill that acts as both a drill and a drive chuck.

There are various types or configurations of drills, but most drilling machines will be divided into four main categories: radial, upright sensitive, upright, and special purpose.

CNC milling uses rotating cutters and vertical motions to remove material from the surface of a workpiece, while CNC drilling and turning allow engineers to create holes and shapes in a blank with precise lengths and diameters.

For China OEM CNC Drilling Products, Choose Runsom Precision

Runsom is a reliable partner for precision CNC machining and drilling. Our team of experts boasts comprehensive knowledge of mechanical design, programming, and machining techniques to make sure each part is produced with high performance and tight tolerance.

We only work with reputable suppliers to assure the authenticity of materials used in part processing and verify compliance upon arrival through our X-ray fluorescence (XRF) analyzers. Our QC team performs in-process inspection and testing to make sure each part is produced exactly to your specifications. Count on Runsom, you will benefit from our exceptional services highly sought after across a wealth of industries.

Quick quotes for your custom CNC drilled components can be created in just a few clicks.