Threaded fastener connections can be loosened due to shock and vibration. This is because friction, bolt stretching, and compression between the threads of the two pieces are not enough to hold them together. To counteract this, lock nuts have been created to provide extra resistance to vibrations, as they have a design that is better suited for this purpose than traditional nuts with single-threaded holes.

Lock nuts come in different designs and types depending on various applications. This guide will help you understand what lock nuts do, how many types they have, how they work, how to use them, common sizes, and alternatives to them.

What Is the Lock Nut?

A lock nut, also known as locknut, locking nut, and self-locking nut, is a type of nut that is used to secure a bolt or other fastener in place. It works by compressing the components it is securing once it is tightened. Locknuts are designed with a special locking feature that helps to prevent the nut from vibrating loose and becoming unfastened. They are available in different sizes and styles and can be used for a variety of applications, such as securing electrical connections, fastening two pieces of material together, or attaching a machine part to a stationary object.

How Does Lock Nut Work?

Lock nuts are special fasteners that are used to secure a bolt in place and prevent it from coming loose due to vibration or other forces. They are also known as jam nuts or self-locking nuts. They are typically made from metal and either have a hexagonal or square shape. A lock nut is used by first threading it onto the bolt until it is snug against the material it is securing. Then, a second nut is tightened against the lock nut, which causes the teeth of the lock nut to grip the threads of the bolt, locking it in place.

Different Types of Lock Nuts

Metal and nylon insert lock nuts are among the most common types of locknuts available. They come in a range of shapes and sizes. To help in understanding and recognizing the different types, here is a list of the common lock nuts along with illustrations.

1. Prevailing torque locking nut/Stover lock nut

This type of nut is designed to remain in place with a constant, even torque. It has a built-in locking feature that prevents it from loosening when exposed to vibration or dynamic loads. Resistance to rotation occurs during assembly and disassembly when tightening a prevailing torque lock nut. This requires the use of a wrench and more torque than standard nuts.

2. Nylon insert lock nuts

This nut is designed with a nylon insert that is positioned inside the nut, creating a locking feature. The nylon insert grips the screw threads, which prevents it from vibrating loose. It is usually used on threaded rods and other items that are exposed to vibration and dynamic loads.

3. Hex jam nuts

This is a type of nut that is designed to be used with a standard hex nut. The jam nut is a thinner version of the hex nut, which is used to keep the hex nut from loosening. It is typically used in applications where you need to secure two parts together, such as a bolt and a nut.

4. Two-way lock nut/Center lock nut

This type of nut is designed to provide a stronger locking force than a standard hex nut. It has two hexagonal faces on either side of the nut, which provides a greater locking force when tightened. Both Stover lock nuts and two-way lock nuts utilize twisted threads to stop the nut from loosening. The difference is that the twisted threads of a Stover nut are at the top, while a two-way nut have it located in the middle.

5. Serrated Flange lock nut

This nut is designed with a serrated flange that grips onto the screw threads, creating a secure, locking force. It’s usually used in applications where you have some type of sheet metal or something that has metal.

6. Keps K-Lock nut

This nut is designed with a ribbed flange that grips onto the screw threads, creating a strong locking force. Be careful not to overtighten when the wing is tightened. As once you do that, it is no longer a locknut, and the free rolling washer is crushed and not available anymore.

7. Castle lock nut/Castellated nut

This type of nut is designed with a round, castellated top that creates a locking force when tightened. It is typically used in applications where there is a need for low torque, such as holding a car wheel bearing in place.

8. Knurled nuts

This type of nut is designed with a knurled surface on the external threads, which helps to lock the nut onto the bolt or other parts. A Knurled nut is not usually the preferred choice when an extremely tight fit between the nut and a threaded rod or bolt is required. However, they are convenient when needing to frequently take apart or reassemble a connection, or when there is a need to avoid the risk of over-tightening or damaging the threads.

9. Wedge lock nuts

This type of nut is designed with a wedge shape that wedges into the screw threads, creating a strong locking force when tightened. They are usually pre-assembled, which means they are one-piece fasteners. They can be reused on bolted joints and are ideal for demanding applications needing bearing heavy loads and vibrations.

Sizes

- Metric

Standard thread sizes range from M3 to M20 and lock nuts generally range from M25 to M50, with larger sizes such as M60 and M85 available online. Common lock nut widths include 5.5mm, 6mm, 7mm, 8mm, 10mm, 11mm, 12mm, and 13mm. - Imperial

- UNC (Unified coarse pitch threads)

UNC have diameters ranging from 0.0730” to 0.2160”, and numbers ranging from No.1-64UNC to No.12-24UNC, while fractions measure larger diameters, starting at 1/4”-20UNC and going up to 6”. - UNF (Unified fine-pitch threads)

UNF have diameters ranging from 0.0600” to 0.2160”, and numbered lines ranging from No.0-80UNF to No.12-28UNF for these sizes. Fractions signify larger diameters, ranging from 1/4”-28UNF to 1.1/2”-12UNF, with the smallest size being No.12-32UNEF and the largest diameter being 1.11/16”-18UNEF.

- UNC (Unified coarse pitch threads)

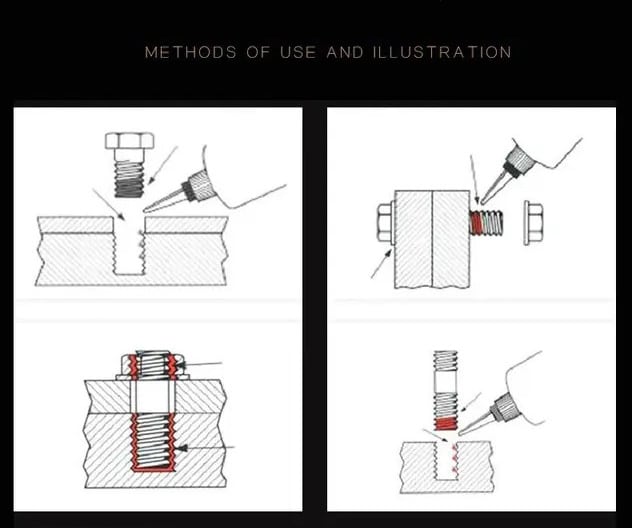

How to Use Locking Nuts

When it comes to how to secure nuts on bolts, the answer is slightly different depending on which locking nut you are using. Generally speaking, the initial threading and finger-tightening is done in the same way as for a standard hex nut. You then need to use a wrench or similar tool to tighten the nut further until it is secure.

In some cases, it is easy to determine which end of a lock nut is to be fastened first, as certain friction or torque-based designs can only be locked correctly in one direction. However, it is important to note whether the nut has a clockwise or anticlockwise threading.

It may be necessary for other designs and brands of lock nuts to use a lock nut washer with the nut to ensure a fully secure lock.

Alternatives

It’s practical to use different sealing methods as alternatives to lock nuts, such as safety wire, thread-locking fluid, and oval-shaped nuts.

- Safety Wire

Safety wire, also known as locking wire, is a system which provides a firm grip and prevents different types of fasteners from slipping out of place. This can be particularly important in contexts like aircraft and car racing, where vibration and other forces can cause components to come loose. In order to ensure that the clasps are secure, safety wiring is often employed.

Safety wire comes in various gauges and materials, depending on the desired application. Stainless steel is a popular choice for this purpose, with a 0.032 in (0.81 mm) diameter often used in aircraft and racing contexts. The wire is looped through drilled holes in fasteners or parts, twisted and secured to a second fastener or leg, and then twisted once more.

- Thread Locking Fluid

Thread-locking fluid, commonly referred to as thread-locker, is a type of adhesive that does exactly what its name implies – it “locks” fasteners in place. It is applied to the threading of the fastener and then solidifies, securing the fastener and preventing it from coming undone.

Thread-locking fluid has been around for over half a century. It was designed in the mid-1950s by Vernon K. Krieble, an American engineer and educator. After inventing this revolutionary new glue, Krieble founded the company Loctite. Since then, many other companies have produced and sold thread-locking fluid.

Get Your Custom CNC Machined Lock Nuts from Runsom

Runsom is a specialist in CNC machining and Swiss-type screw machining to produce threaded spacers, knurled parts, pins, vents, fittings, spacers, bushings, inserts, and machined washers. With extensive experience and incredible machining capabilities, we also can deliver lock nuts in a wide variety, including nuts with special threads and dimensions, slotted nuts, special all metal lock nuts and nylon insert lock nuts, and panel nuts. Request an instant quote online today!

Other Articles You May be Interested in: