Stainless steel is a highly versatile material that is extensively utilized in various industries. It is available in multiple grades, each with its own set of unique characteristics. This article will focus on a comparison between two frequently employed stainless steel grades: 304 and 201 stainless steel.

The article aims to present an overview of the unique characteristics of 201 and 304 stainless steel, as well as the benefits of their properties in specific projects. It will delve into their distinct physical and mechanical properties and outline methods for identification to help you select the exact one for your specific application.

What is 304 Stainless Steel?

Stainless steel 304 is distinguished by its higher nickel content, setting it apart from other types of stainless steel. It consists of 18% chromium and 8% nickel. This higher nickel content contributes to its slightly higher cost compared to other types. However, it’s this nickel content that makes type 304 stainless steel less prone to corrosion, making it an excellent choice for environments with high water or moisture levels.

What is 201 Stainless Steel?

Stainless steel 201 was specifically developed as a response to increasing nickel prices, making it a more affordable option. However, due to its lower nickel content, it is not as effective in preventing corrosion. Like 304 stainless steel, it belongs to the category of austenitic stainless steel.

In cold environments, 201 stainless steel demonstrates its strength and durability, as it maintains toughness even in cold weather. To compensate for its lower nickel content, it contains higher levels of manganese and nitrogen. This makes type 201 stainless steel particularly attractive as it is the most cost-effective option.

The higher levels of manganese contribute to the superior strength of type 201 stainless steel compared to other types. Industries that prioritize durability at a lower cost, without significant concern for exposure to corrosive elements, often prefer this type.

Stainless Steel 201 vs 304: The Difference Explained

In this section, we’ll compare stainless steel 304 and 201 from several aspects such as their chemical composition, cost, performance characteristics, mechanical properties, uses, appearance, etc.

1. Composition

- 304 Stainless Steel: This type of stainless steel falls into the category of austenitic stainless steel and is characterized by a higher chromium content. It has good luster and brightness and is resistant to rusting.

- 201 Stainless Steel: Serving as a more affordable option, 201 stainless steel contains a significant amount of manganese. It features a dark light surface and has a tendency to rust more easily. Additionally, it contains manganese and nitrogen, which contribute to its unique properties.

| Grade | Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) |

| AISI (304) | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18-20 | 8-10 |

| AISI (201) | ≤0.15 | ≤1.00 | 5.5-7.5 | ≤0.05 | ≤0.03 | 13.5-15.0 | 3.5-5.5 |

2. Corrosion Resistance

Increased levels of chromium and nickel result in improved corrosion resistance. For instance, 304 material contains 8-10% nickel and 18-20% chromium. This composition ensures that stainless steel will generally not rust in normal circumstances.

304 stainless steel stands out for its exceptional corrosion resistance, making it a perfect choice for applications that face harsh environmental conditions or corrosive substances. In contrast, 201 stainless steel has lower corrosion resistance and may not be the most suitable option for aggressive conditions.

3. Mechanical Properties

- Hardness and Toughness

201 stainless steel exhibits higher stiffness compared to 304 stainless steel, but its toughness is not as good as 304. On the other hand, 304 stainless steel offers superior fatigue resistance. - Formability

While both grades are capable of being formed, 201 stainless steel is characterized by its higher malleability and ease of shaping, making it beneficial for various manufacturing processes. - Durability

Both 201 and 304 stainless steel are known for their durability. Nevertheless, 304 stainless steel surpasses 201 stainless steel in terms of corrosion resistance. This enhanced resistance allows 304 stainless steel to withstand exposure to saltwater, acids, and other chemical substances more effectively.

4. Cost

- 304 Stainless Steel: Although it may come with a higher price tag, the outstanding corrosion resistance and overall performance of 304 stainless steel make it well worth the investment in critical applications that prioritize reliability and longevity.

- 201 Stainless Steel: With a reduced nickel content and fewer alloying elements, 201 stainless steel typically offers a more economical option compared to 304. This affordability factor makes it a favored choice for projects with budget constraints.

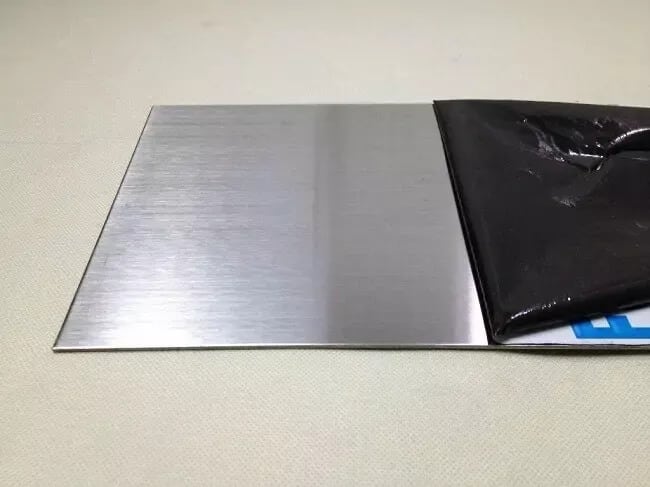

5. Appearance

- 304 Stainless Steel: 304 stainless steel is composed of a higher chromium content, resulting in a brighter appearance and increased resistance to oxidation.

- 201 Stainless Steel: 201 stainless steel contains a higher proportion of manganese, giving it a darker surface with less brightness that is more prone to rusting.

6. Application

- 304 Stainless Steel: it has gained recognition as food-grade stainless steel. It is renowned for its widespread usage as a heat-resistant steel, primarily found in food production equipment, chemical equipment, nuclear power applications, and more.

- 201 Stainless Steel: it offers an economical alternative to 304 steel. It exhibits magnetic properties after undergoing cold processing. It’s commonly employed in applications such as railway vehicles or building decoration that require less strict requirements.

7. Maintenance

Both types of stainless steel have low maintenance requirements. In contrast, 304 stainless steel may require slightly less attention compared to 201 stainless steel as it offers a higher degree of corrosion resistance.

8. Features Benefits

- 304 stainless steel: 304 stainless steel is renowned for its exceptional resistance to corrosion and intergranular corrosion.

- 201 stainless steel: 201 stainless steel exhibits decent resistance to acids and alkalis, along with characteristics such as high density and a polished finish without any bubbles or pinholes.

How to Distinguish Stainless Steel 201 and 304?

Below are a few simple methods to distinguish between these two materials in sheet metal fabrication:

1. Manual touch and surface finish

In the case of stainless steel water tanks utilizing 304 and 201 stainless steel, the surface is typically matte. By visually inspecting and hand touching, we can differentiate between the two.

304 stainless steel exhibits a good level of luster and brightness and has a smooth texture when touched. On the other hand, 201 stainless steel feels rough and lacks a shiny appearance.

Additionally, a simple test involves wetting the hand with water and touching both types of stainless steel sheets. After touching, the water stain or fingerprint on the surface of 304 sheets is relatively easy to remove, while it’s harder to remove water stains or fingerprints from 201 stainless steel sheets.

2. Grinding spark status

When iron and steel are subjected to high friction and temperature, the oxidation of various elemental particles produces sparks with distinct characteristics. Different types of steel will result in variations in the quantity, shape, bifurcation, and color of these sparks. This method is useful for determining the chemical composition and approximate content of the materials.

To apply this method, gently polish both 201 and 304 stainless steel using a grinding machine with a grinding wheel. When grinding 201 stainless steel, sparks tend to be longer, thicker, and more abundant, with a trailing pattern. Conversely, when grinding 304 stainless steel, sparks are usually shorter, thinner, and less abundant, also with a trailing pattern. Consistency in the grinding process should be ensured to facilitate accurate comparison and distinction.

3. Pickling agent

Apply a stainless steel pickling paste to both types of stainless steel sheets separately. After allowing it to sit for 2 minutes, observe the color change on the surface of the stainless steel. The 201 stainless steel should exhibit blackening, while the 304 stainless steel should either whiten or show no discoloration.

4. Spectrometer detection

Spectrometer detection offers an alternative approach, known for its scientific, straightforward, and widespread use, especially for companies making large-scale material purchases.

This method rapidly measures the elemental composition of the stainless steel through a spectrometer, enabling the identification of whether the material is 304 or 201. The reliability and credibility of this method are comparable to the chemical analysis conducted by third-party national testing centers.

5. Presence of magnetism

It’s feasible to employ the magnetic adhesion method to identify these two materials. 201 stainless steel is generally magnetic, whereas 304 stainless steel is typically non-magnetic.

However, it is essential to note that certain variants of 304 stainless steel can exhibit magnetic properties due to variations in production processes. Therefore, relying solely on the presence or absence of magnetism is not considered a reliable method for distinguishing between 201 and 304 stainless steels.

How to Choose between 201 and 304 stainless steel?

- The lower unit price of 201 stainless steel makes it a more cost-effective choice, particularly when the requirements for toughness and corrosion resistance are not as demanding.

- 304 stainless steel is more cost-effective and offers a wider range of applications. It is the ideal option when specific requirements for toughness, corrosion resistance, and durability need to be met.

- 304 stainless steel is suitable for food-grade applications, while 201 stainless steel is not recommended for such purposes. When considerations for future maintenance and corrosion resistance are not prioritized, 201 stainless steel can be utilized for structural parts, decoration, and as inner and outer liner materials for non-food contact containers, among other applications.

- It is generally advised against using 201 stainless steel for insulation cups, kettles, and similar applications.

Conclusion

When deciding between 304 and 201 stainless steel, the choice should be based on the specific requirements of your application. 304 stainless steel, with its higher nickel and chromium content, offers superior corrosion resistance, toughness, and durability. This makes it a suitable option for various applications that prioritize performance. On the other hand, 201 stainless steel is a cost-effective choice that performs well in less demanding environments or applications where formability and affordability are crucial.

By gaining a comprehensive understanding of the distinctions between stainless steel 201 and 304, you can make an informed decision and choose the most appropriate stainless steel grade for your project. This ensures optimal performance and longevity, resulting in a successful outcome for your project.

Stainless Steel CNC Machining Services – Runsom Precision

If you’re considering stainless steel as the material for your CNC machining project, you can be confident that you’re selecting a material with plenty of advantageous properties. However, due to the versatility of CNC machining, choosing the right stainless steel from the list of materials can be a challenge.

At Runsom Precision, our team of engineers embraces challenges, drawing on decades of engineering experience. We specialize in material selection, ensuring that you find the perfect stainless steel for your specific project. With our extensive expertise and state-of-the-art 3-, 4-, and 5-axis CNC machines, we can manufacture high-quality stainless steel parts for complex projects with exceptional precision and tight tolerance. This results in parts that meet the specified requirements while saving time and cost. Request an instant quote to get started with your Stainless Steel CNC Machining project now!

Other Articles You May Be Interested in: