Custom Parts Manufacturing for the Aerospace Industry

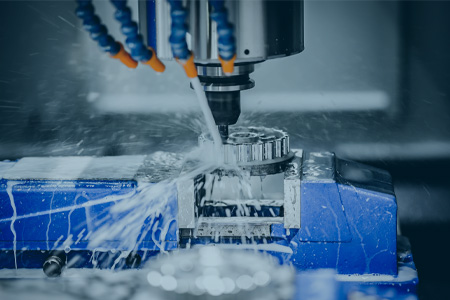

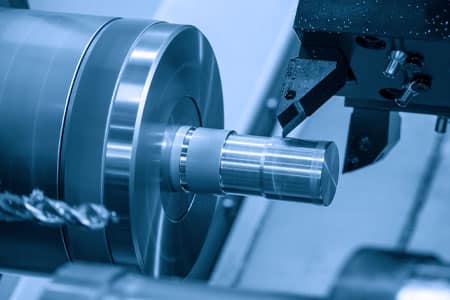

Over years, Runsom has delivered a number of high precision parts and components with excellent quality and intricate geometries for aerospace and aircraft industries, ensuring each product you receive exactly matches your critical specifications and budget. Our top-notched facility is unique in its ability to complete the most challenging manufacturing, dimensional tolerance, and cleanliness job. The dedicated staff members, and well-equipped CNC machines, along with years of experience, allow us to produce aerospace machined parts with durability, consistent quality, and tight tolerance within a rapid lead time. Product developers, designers, and manufacturers in the aerospace sector always trust us to fit their special and sophisticated requirements for crucial applications affordably and cost-effectively.

What is Aerospace CNC Machining?

Aerospace CNC machining is the manufacturing of components used to assemble and maintain aircraft and space shuttles. CNC machined parts, kits, and assemblies are highly demanding for aircraft in the aerospace industry. Components used for aerospace equipment and aircraft require to be manufactured precisely to function properly, such as manifolds, bushings, hinges, clamps, or other custom components. Aluminum, titanium, and Kovar are the common materials used for making aerospace components. Other materials like brass, stainless steel, copper, bronze, Inconel, and some plastics are also available for CNC machining aerospace parts.

Our Capabilities and Aerospace CNC Machining Services

Runsom makes custom aerospace machined parts in premium materials with our advanced CNC machining techniques. The combination of quality awareness, top-notched CNC equipment, and expertise and knowledge is our assurance for every customer and order. Our CNC machining services serving the aerospace industry include:

Materials Available for the Aerospace Industry

There are a range variety of material types for your selection to meet the requirements of your aerospace machined parts. Materials used in its component manufacturing for the aerospace industry must be carefully selected. In general, they should be durable and strong while maintaining fairly lightweight. Part of the common materials we use for CNC machining of aerospace components includes:

Aluminum

Aluminum is an excellent choice for high load requirements on aircraft brackets and housings due to its incredible strength-to-weight ratio. It has an excellent strength-to-weight ratio of this metal. Aluminum also possesses high corrosion resistance, ductility, machinability, and stiffness.

Aluminum is an excellent choice for high load requirements on aircraft brackets and housings due to its incredible strength-to-weight ratio. It has an excellent strength-to-weight ratio of this metal. Aluminum also possesses high corrosion resistance, ductility, machinability, and stiffness.

Its lightweight properties make it useful in aerospace structural applications such as wing skins, fuselage skins, wing stringers, etc.

Price: $

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Lead Time: < 10 days

Titanium

Titanium is an ideal metal for demanding applications as a result of its outstanding properties, including great tolerance to corrosion, chemicals, and extreme temperatures, as well as an excellent strength-to-weight ratio.

These properties make titanium a perfect choice for space vehicles and aircraft engines.

Price: $

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Wall Thickness: 0.75 mm

Lead Time: < 10 days

Stainless Steel

Stainless steel is a kind of low-carbon steel with desirable properties for many industrial applications. Stainless steel usually comprises at least 10% chromium (by weight).

They are the best choice for critical joints in aircraft superstructures, engine and exhaust components, and landing gear components, ensuring high durability and performance.

Price: $

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Wall Thickness: 0.75 mm

Lead Time: < 10 days

Carbon Fiber

Thanks to their specific stiffness and strength, carbon fiber-reinforced polymers are widely used in the aerospace industry. They also possess greater resistance to fatigue and corrosion, making them ideal for structural components such as control surfaces, wing boxes, and fuselages.

Liquid Silicone Rubber

Our liquid silicon materials are excellent options for thermal flexibility and stability. They keep good properties in the harsh environment of the aerospace industry to ensure the vehicle performs normally.

Surface Finishing Available for Aerospace Parts

Once the CNC machining process is completed, it may require some surface finishing methods to enhance the mechanical properties or aesthetic qualities of your aerospace machined parts. We offer extensive post-processing operations to help to strengthen the wear and corrosion resistance of these products and further improve their performance.

Powder coating

Powder coating is a type of process applied in the form of a free-flowing dry powder. Unlike traditional liquid paint that is delivered by evaporating solvents, powder coating is usually applied electrostatically, and is then cured with heat or UV light.

Materials: Aluminum, steel, stainless steel

Color: Black, any Pantone number or RAL code

Texture: Semi-gloss or gloss

Anodizing

This process is available for improving parts' resistance to corrosion and wear, and enhancing the rigidness so that the part surface is protective.

Materials: Aluminum

Color: Grey, red, blue, gold, clear, black

Texture: Matte, smooth finish

Polishing

Polishing is applied to create a shiny and smooth surface, either via chemical interference or physical rubbing of the part. This process forms a surface with strong specular reflection, but can also reduce diffuse reflection in some materials.

Materials: Aluminum, brass, stainless steel, steel

Color: n/a

Texture: Glossy

Electroplating

It is a process preferred by lots of industries, especially the automotive sector where chrome-plating of steel parts is common.

Materials: Aluminum, stainless steel, steel

Color: n/a

Texture: Glossy, smooth finish

Brushing

Brushing is a process usually for aesthetic purposes, in which marks are drawn on the surface of a material with an abrasive belt.

Materials: Aluminum, stainless steel, steel, brass, ABS

Color: n/a

Texture: Satin

Applications of CNC Machined Aerospace Parts

The production of a broad array of aerospace parts with special requirements can be accomplished by our unmatched in-house capabilities. And our CNC machined aerospace components are widely used in this industry for different applications.

| Bearings and seals | Wire wrap insulation |

| Turbo pumps and manifolds | Gas and liquid flow components |

| Conformal cooling channels | Aircraft tray tables |

| Aircraft windows and canopies | Turbine blades |

| Panel and gears | Valve components |

| Fuel nozzles | Electrical connectors |

| Heat exchangers | Filter bodies |

Partnering with Runsom Confers You Unmatched Advantages

At Runsom, we continuously forge ahead to keep innovative and advocate the development of the CNC machining industry to confer more benefits for our customers. The reason why we outperform other aerospace machine shops is that we offer the most competitive price through highly efficient methods without the expense of quality. With craftsman spirits and commitment to the highest standards, we utilize state-of-the-art CNC machining technology to serve clients around the world across broad industries and fields.

We offer one-stop services ranging from design, manufacturing, surface finishing, assembly, and shipping.

Every single special need or challenging feature you require can be met with our expertise and versatility.

We are proficient in creating ultimate precision parts at high-volume production for aeronautic instruments.

Our proven processes enable us to perform good quality, low costs, and flexibility on each project.

Well-trained machinists and technicians assure each stage of the aerospace machining process runs smoothly.

Our aerospace parts are machined so precisely as to fit into the project as a whole and its application of use.

The design reviews or solutions we suggest are all based on the hundreds of thousands of orders we dealt with.

The integrated system we develop allows for on-time delivery regardless of the order quantity.

Aerospace CNC Machine Shop & CNC Machining Services

Aerospace is one such sector where ultra-precision and accuracy are significantly important for functioning well. It typically refers to crucial applications including the design and manufacture of aircraft, satellites, missiles, and more. So there is no room for any error, otherwise, the consequence may be severe and disastrous. Therefore, all respects of the selection of materials, manufacturing process, and expertise affect the final results directly.

We at Runsom Precision focus on aerospace precision machining for over decades and have been delivering a variety of interior and exterior components for aircraft vehicles and instruments from plastics and metals. Our highly skilled team of engineers and technicians masters the latest technologies and employs exceptional CNC machines to tackle the most challenging tasks and create aerospace machined parts that perfectly match customers’ requirements even exceeding their expectations.