The prevalence of plastics is ubiquitous in our daily lives. Two types of transparent plastics frequently utilized for laminates are Acrylic (PMMA) and PVC. When deciding between the two, how do they differ, and which is the best choice? This article aims to provide a comparison of these two materials for guidance.

PVC

What Is PVC Plastic?

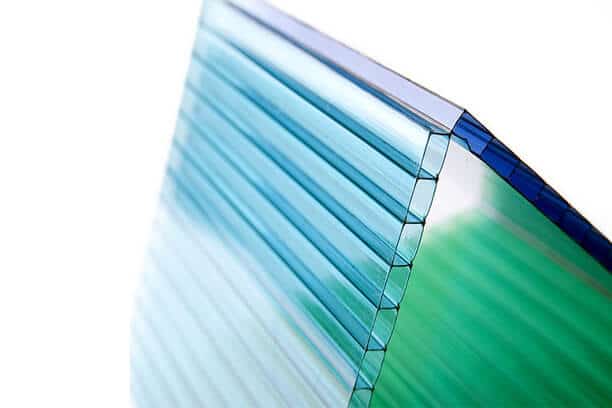

Polyvinyl chloride (PVC or Vinyl), a type of thermoplastic polymer commonly used in various applications worldwide, is one of the most widely produced thermoplastic polymers (third after PET and P.P.). It is made from ethylene carbon atoms and is available in both rigid and flexible forms. The usage of PVC is universal, and it is used in medical devices, wires, cables, pipes, etc.

Basic Forms of PVC

Here, we’ll explain the different types of PVC that are available. PVC comes in two categories – Flexible and Rigid, however, there are other types:

- Flexible PVC, or Plasticized PVC (Density: 1.1-1.35 g/cm3), sometimes called as PVC-P, has a lower crystallinity due to the addition of compatible plasticizers. This results in a clearer and more flexible plastic.

- Rigid PVC, or Unplasticized PVC (Density: 1.3-1.45 g/cm3), also known as UPVC, PVC-U or uPVC, is a stiff and cost-effective plastic that is resistant to chemicals, impact, water, weather, and corrosion.

- Chlorinated Polyvinyl Chloride (CPVC) is produced by the chlorination of PVC resin. This type of PVC has a high chlorine content which makes it durable, chemically stable, and fire-resistant. CPVC can endure a broader range of temperatures.

- Molecular Oriented PVC (PVC-O) is made by rearranging the disordered structure of PVC-U into a layered structure. When PVC is bi-axially oriented, it gains better physical properties like rigidity, resistance to wear and tear, reduced weight, and more.

- Modified PVC (PVC-M) is an amalgamation of PVC that uses modifying agents to increase its toughness and impact-resistant ability. This method enhances PVC’s impact strength, making it more durable.

Properties

PVC is known for its versatility and cost-effectiveness. This material possesses several notable properties and benefits, including:

- Good durability: PVC is a standout option due to its resistance to weathering, chemical rotting, shock, abrasion, and corrosion. This makes it a popular choice for long-term and outdoor products.

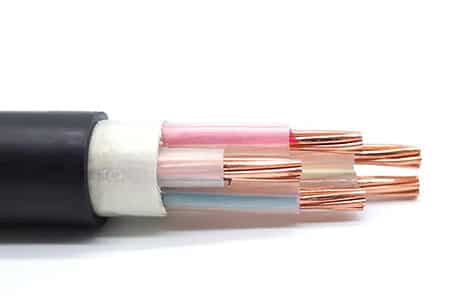

- High dielectric strength: PVC serves as a reliable insulation material, making it ideal for various electrical applications.

- Cost-effectiveness: Compared to other materials, PVC provides a favorable cost-performance ratio. It offers impressive physical and mechanical properties, and it requires minimal maintenance for a long lifespan.

- Flame retardant: PVC products are also effective as flame retardants due to their high chlorine content. An oxidation index of ≥45 and the use of antimony trioxide in combination with phosphate ester plasticizers contribute to great fire performance and mechanical properties.

- Chemical resistance: PVC shows resilience against all inorganic chemicals, as well as diluted acids, diluted alkalis, and aliphatic hydrocarbons.

- Mechanical properties: PVC is known for its abrasion resistance, light weight, and toughness.

Pros and Cons

| Flexible PVC | Rigid PVC | |

| Strengths | Great electrical insulation properties Low cost High-impact strength Flexible Non-flammable & versatile Easier processing than rigid PVC Good resistance against UV, acids, alkalis, oils, etc. | Inherent flame retardant High stiffness at a low cost Suitable for transparent applications & FDA compliant Better chemical resistance than plasticized PVC Great electrical insulation & vapor barrier properties High dimensional stability at room temperature |

| Shortcomings | Unsuitable for food contact with some plasticizers Lower resistance to chemicals than rigid PVC Properties may change over time with plasticizer migration A tendency to degrade at high temperatures | Limited resistance to cracking under solvent stress Challenging to process it to melt point A low continuous service temperature of 50°C It becomes brittle at 5°C (unless modified with impact modifiers or processing aids) |

Common Uses

PVC is a popular material used in a multitude of applications due to its unique properties. PVC plastic is hard-wearing and doesn’t corrode easily, making it resistant to germs and easy to clean. It’s also resistant to chemicals and is non-conductive. It is used in various medical products. With high durability, PVC is also extensively used in the construction industry. And it can be a good substitute for stainless steel and other synthetic materials. Due to its durability and weather resistance, it is frequently used in outdoor applications.

1. Construction and building

The majority of PVC/vinyl produced is used in the building and construction industry due to its durability and resistance to moisture and abrasion. The material doesn’t corrode and can be easily cleaned without the need for frequent painting.

2. Wiring and cables

PVC is a widely trusted material in electrical wiring and cables due to its ability to withstand tough conditions, including exposure to changing temperatures and dampness, for the life of a building.

By creating pipes that are virtually leak-free, resistant to environmental stress, and not prone to corrosion, PVC helps conserve energy and water. Compared to cast metal systems, PVC breakage rates are greatly low. PVC piping also improves functionality and increases energy efficiency due to the lack of build-up.

3. Packaging

Flexible PVC is popular in packaging because of its durability, dependability, and lightweight. Clear vinyl is used to make shrinkwrap for consumer products, while the rigid vinyl film is used in blister and clamshell packaging to protect a range of household goods.

4. Healthcare

PVC is critical to the healthcare industry, playing a crucial safety role in dispensing life-saving medicine through IV bags and medical tubing. Thanks to their flexibility and unbreakable nature, PVC blood-collection bags, in particular, were a significant breakthrough.

5. Household products

PVC’s durability, affordability, and water resistance make it ideal for producing household products such as boots, shower curtains, and raincoats.

6. Siding and window frames

PVC is commonly used in producing siding and window frames because of its durability and affordability. Vinyl windows are highly insulated, with three times the heat insulation of aluminum windows.

Acrylic

What Is Acrylic Plastic?

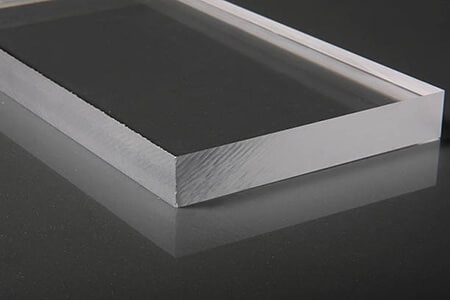

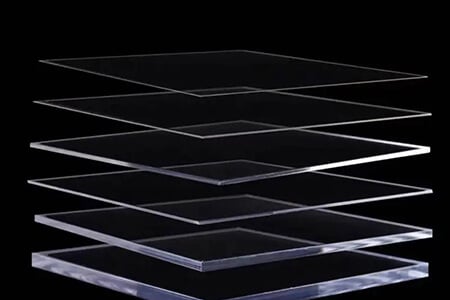

Acrylic, also referred to as PMMA (Polymeric Methyl Methacrylate) and Plexiglas, is a biocompatible plastic material that is transparent and lightweight. It’s commonly used as a substitute for glass because it’s easier to handle and less prone to breaking. The transparency rate of acrylic is 92%, making it one of the clearest materials available. It’s versatile for a wide range of applications.

Properties

1. Lightweight & impact resistance

Plexiglas, a type of acrylic sheet, is incredibly lightweight and impact-resistant. It can resist breakage from shock and does not easily break. It has up to 17 times more impact resistance than ordinary glass, and it is half the weight.

2. Chemical resistance

Acrylic can withstand exposure to various chemicals, making it an ideal material for fluidic devices and medical manifolds.

3. Temperature resistance

Acrylic can withstand temperature changes and is suitable for manufacturing medical manifolds and microfluidic devices. Moreover, it can undergo full heat treatment and diffusion bonding.

4. High transparency & optical clarity

Acrylic plastic has excellent optical properties, with exceptional transparency and clarity similar to glass. It can transmit up to 92% of white light, making it an excellent material for light guides and lenses.

Pros and Cons

Strengths

- High clarity and transparency: Acrylic allows 92% of light to pass through it, which is greater than glass and other plastics.

- High hardness and toughness: Acrylic is known for its high hardness, toughness, scratch-resistance with light weight.

- UV resistance: Acrylic is highly resistant to UV light and weathering, making it great for prolonged exposure to sunlight.

- Chemical resistance: Acrylic is highly resistant to most laboratory chemicals but cannot be used with aromatic or chlorinated hydrocarbons.

- Affordability: Acrylic sheet is much cheaper than standard glass and is easier to cut to size.

- Lightweight with high dimensional stability: Acrylic plastic is 50% lighter than glass, but more durable and stronger.

- Machinability: Plexiglass or clear acrylic offers almost limitless options for processing. You can process these sheets with saw, mill, drill, engrave, glue, polish and bend (with heat) without the risk of breaking.

- Biocompatibility: This property makes it an excellent option for the medical industry.

Shortcomings

- Low scratch resistance: Plexiglass is prone to scratching more easily than regular glass.

- Low impact resistance: While acrylic has superior impact resistance compared to ordinary glass, materials like polycarbonate would be more suitable for situations where durability is the utmost priority, especially in extreme circumstances.

- Low heat resistance: Acrylic’s melting point is comparatively low, precisely 160 degrees Celsius. This low temperature may not be suitable enough for certain engineering purposes.

Learn more about our CNC Machining in PMMA/Acrylic Service

Common Uses

Acrylic is more advantageous than other transparent polymers, such as its outstanding light transmission, limitless coloring options, and high resistance to UV light and weathering. The use of acrylic is widespread in a variety of applications, such as car windows, smartphone screens, skylights, illuminated signs, hockey rinks, and aircraft canopies. However, it isn’t recommended for applications that involve chlorinated or aromatic hydrocarbons, ketones, or esters.

1. Fluorescent light lenses

Acrylic plastic has been successfully formed into lenses that can fit over fluorescent light bulbs. These lenses soften the lighting and eliminate blue light for a healthier, more comfortable environment.

2. Fiber optic wiring

Fiber optic wiring requires a material that can both protect the fiber lining and allow light to transmit. Unlike glass, acrylic remains intact even when bent or stretched, making it more durable and flexible.

3. Sport equipment

Acrylic has become a go-to material for making performance shoes, tennis racket handles, bike helmets, and more since this plastic material is not only strong but also lightweight.

4. Water resistance paint

By adding traces of acrylic plastic to paint, manufacturers create a product that can repel splashes and moisture. While primarily used in car paint, acrylic paint is beginning to make its way into house wall paint.

5. Home decoration

Acrylic’s transparency and versatility have made it a popular choice in the furniture and decoration industry. It has become an excellent alternative to glass for making cabinets, splashbacks, coffee tables, and decorative panels.

6. Military Use

Acrylic is commonly used in submarine windows and airplane cockpits due to its adaptability, high strength under pressure, and transparency. This material is also useful for breaking the sound barrier and diving deep into the ocean.

7. Aquariums

Aquariums and shark tanks require a material that is both sturdy and clear. While glass was the standard material of choice, acrylic has been gaining popularity due to its ability to meet all the required specifications at half the cost of glass. It’s transparent, strong, and resistant to shattering, making it the ideal option for aquariums.

Comparison Chart of PVC & Acrylic

This chart summarizes the difference between PVC and acrylic in several key properties:

| PVC (Flexible/Rigid) | Acrylic/PMMA | |

| Cutting/Fabricating | Can cut, weld, and bend into molds and fittings | Easier to chip or craze |

| Strength/Durability | 1.0 ft-lbs./in. | Scratch-resistant |

| Clarity | Not Bad | Excellent; Can also be polished |

| Stiffness/Flexibility | Rigid 481,000 psi | Rigid 480,000 psi |

| Chemical Resistance | Resistant to: inorganic acids, alkalis, alcohols, fats, oils, aromatic-free petrol, salt, and common corroding agents. Not suitable for: chlorinated hydrocarbons, ethers, esters, or ketones. | Resistance to: hydrocarbons, detergents, inorganic chemicals, fats and lipids, and acids at room temperature. Not resistant to: alcohol or methylene chloride. |

| UV Resistance | Yellows over time when exposed to sunlight | Will not yellow |

| Temperature Resistance | Low | Medium |

| Tensile/Pull Strength | 7,500 psi | 10,000 psi |

| Insulation/Dielectric Strength | Low | Medium |

| Masking Options | Plastic/Film | Plastic/Film or Paper |

| Forms Available | Sheet & Tube | Sheet, Rod, & Tube |

Main Differences

In this part, we’ll distinguish PVC and acrylic plastics from five main aspects:

1. Strength and Durability

In terms of strength and durability, PVC is not as strong as acrylic. Acrylic is extremely durable and strong, making it a better option in terms of overall strength.

PVC has a high impact resistance, as well as good heat and weather resistance, but is not able to maintain its strength in extreme conditions. Acrylic, on the other hand, has a higher impact strength than PVC, is UV resistant and is able to withstand high temperatures, and is also shatter-proof.

Therefore, if you are looking for a material that can withstand extreme weather conditions, high impact, and high temperatures, it is recommended to use acrylic rather than PVC.

2. Cost-effectiveness

From a cost-effectiveness perspective, PVC is generally a more affordable option compared to acrylic. This is due to the fact that PVC is a type of plastic that is widely produced and readily available, making it more cost-effective to manufacture and purchase. On the other hand, acrylic is a type of thermoplastic that requires more complex manufacturing processes, which can drive up the production costs.

However, it is important to note that cost-effectiveness is just one factor to consider when choosing between PVC and acrylic. Other factors to consider include durability, aesthetics, and chemical resistance. Ultimately, the choice between these two materials will depend on your specific needs and requirements.

Thus, if cost-effectiveness is your primary concern, then PVC may be the better option for you. However, if you are willing to pay a higher price for the benefits that acrylic can offer, such as superior clarity and durability, then it may be worth considering as well.

3. Sustainability

PVC is known for being non-biodegradable and takes a long time to decompose. It can also release harmful chemicals when burned, leading to environmental and health concerns. On the other hand, acrylic is generally considered a more sustainable option as it is recyclable and can be made into new products.

In terms of energy consumption, PVC requires more energy to produce than acrylic. PVC is made from petroleum, a non-renewable resource, whereas acrylic is made from natural gas, which is becoming increasingly abundant due to advances in extraction techniques.

Based on these factors, it can be concluded that acrylic is a more sustainable option than PVC in terms of its biodegradability, recyclability, and lower energy consumption. However, it is important to note that both materials can have negative environmental impacts if not properly disposed of or recycled.

4. Appearance

With regard to appearance, PVC has a shiny, plastic-like look and is opaque while acrylic has a glass-like clarity and transparency. Acrylic is also shinier compared to PVC, and has a higher light transmission rate. However, PVC is available in a wider range of colors compared to acrylic.

While both PVC and acrylic have their unique properties and applications, acrylic stands out in terms of appearance due to its transparency, clarity, and shine. Meanwhile, PVC remains a popular choice for its availability in a variety of colors and opaque nature.

5. Machinability

PVC is a tough, rigid plastic that can be easily machined using tools such as saws, drill bits, and routers. It has good dimensional stability and excellent chemical and weather resistance.

Acrylic is a softer plastic that is more brittle than PVC. It can be machined using similar tools as PVC, but requires sharper and more precise cutting edges to avoid cracking or chipping.

In conclusion, both PVC and acrylic are machinable materials that can be used in a variety of applications. PVC is a more durable and rugged material, while acrylic is more fragile but offers superior optical properties.

Conclusion

To sum up, PVC is a cost-effective option that is easier to install and does not require frequent maintenance, while acrylic offers better clarity, durability, and impact resistance. Selecting the appropriate material for your project can be intricate and crucial for the final result. We hope this article has aided you in making a decision on the finest option.

Work with Runsom to Make Your CNC Machined PVC/Acrylic Parts

CNC machining is a commonly used method for creating parts from PVC and acrylic materials since they can easily be machined with high precision and accuracy using CNC equipment. Runsom Precision is proficient in producing PVC and acrylic parts with both CNC machining and precision fabrication services. If you require further guidance, don’t hesitate to contact us, and our proficient team will gladly assist! Get an instant quote today!

Other Articles You May be Interested in: