Polycarbonate and acrylic are commonly used in place of glass for various applications, as they have a similar appearance and are transparent. However, it can be challenging for users to decide which material to use. While both these two plastics share a few characteristics, they differ significantly in several ways. Thus, to make the best choice between the two, it’s necessary to understand their unique features.

This article aims to compare polycarbonate and acrylic in terms of their properties, costs, applications, pros and cons, and alternatives, to help you choose the appropriate material for your project.

What Is Polycarbonate Plastic?

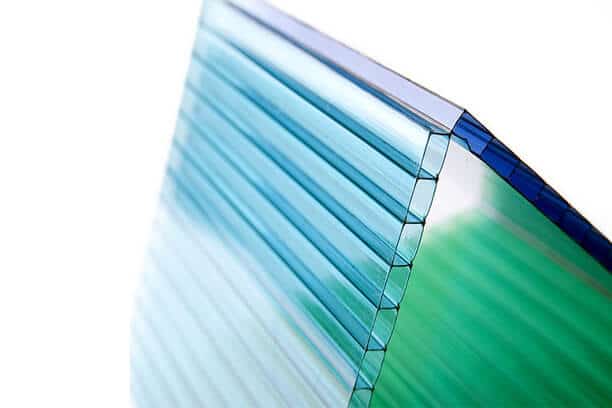

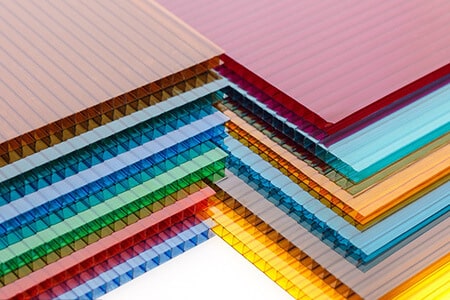

Polycarbonate, a thermoplastic polymer material, is more transparent than common plastics such as HDPE, PET, and PS, and has a similar level of transparency to silicate glass. It is also widely known for its high impact resistance, surpassing glass by 250 times. However, polycarbonate has a low resistance to scratches.

One unique characteristic of polycarbonate is its ability to deform significantly without cracking or breaking. This specific performance enables it to be processed similarly to sheet metal, including press brakes, rolling, hot-line forming, and heating. These processes allow for the cost-effective and efficient fabrication of polycarbonate into shapes that glass cannot create. Also, polycarbonate can be easily machined and fabricated using injection molding and pressed into sheets varied in thickness.

What Is Acrylic Plastic?

Acrylic, or polymethyl methacrylate (PMMA), can be found in various forms and is marketed under well-known trademark names such as Plexiglas®, Lucite®, and Perspex®. Although each brand may have some unique features, they all come from the same material.

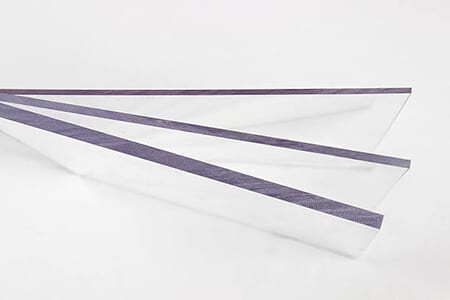

Acrylic plastic, like polycarbonate, is a type of amorphous thermoplastic material. However, compared to polycarbonate and glass, it’s much more transparent and has superior resistance to weathering. In addition, it has the same transparency, clarity, and brilliance as glass, but weighs only half as much and is more resistant to impact. This makes it an excellent choice for anything from durable signs and skylights to attractive retail store displays and fixtures.

Differences between Polycarbonate and Acrylic

Overview

The chart below exhibits the overview of polycarbonate and acrylic: their characteristics, strengths, shortcomings, and applications:

| Acrylic/PMMA | Polycarbonate | |

| Characteristics | Lower cost than glass and polycarbonate 17x impact resistance of glass High optical clarity – 92% light transmittance UV resistance & good weathering Resistant to scratches and dents Can be polished smoothly Shiny surface Available in various colors High dimensional stability Lightweight Easy to machine and heat bent Continuous working temp – 82°C (180F) | Higher cost than acrylic but cheaper than glass 250x the impact resistance of glass Optically clear – 88% light transmittance Highly resistant to chemicals and acids Resistant to chips and cracks Low flammability Available in a range of flexible grades Lightweight Can be cold-formed or bent without heating Continuous working temp – 115 °C (240F) |

| Advantages | Can be polished smoothly Clear glue joint Shiny surface More affordable than polycarbonate Higher machinability than polycarbonate Higher light transmittance and clarity than polycarbonate | Greater impact resistance than acrylic More flexible grades than acrylic Highly resistant to chemicals and acids Not easy to crack when drilling Non-flammable Can be exposed to high temperatures Lighter in weight than acrylic |

| Disadvantages | Prone to chip and crack when drilling More rigid Shouldn’t be exposed to open flames | More likely to be scratched and dented Cannot be polished More translucent than transparent |

| Applications | LED-diffusing lighting panels Indoor and outdoor signs Architectural glazing Food and drink containers Transparent manifolds Exterior windows and craft projects Cosmetics holders, merchandising, and retail store displays | Bullet-resistant and shock-proof windows and barriers Safety guards in industrial settings Windshields and operator protection in various vehicles Consumer electronic components Clear display stands and document holders Semiconductor machinery components Clear containers for holding chemicals Molds and trays for resin casting |

Physical Properties

The chart below compares several key physical properties of acrylic and polycarbonate:

| Property | Acrylic/PMMA | Polycarbonate |

| Hardness (Rockwell M) | 94-105 | 70-75 |

| Impact resistance | 17 times of glass | 250 times of glass |

| Tensile Strength (Ultimate) (MPa) | 65-83 | 28-75 |

| Heat Deflection Temperature (°C) | 110-115 | 127-147 |

| Water Absorption | 0.13-0.80 | 0.03-0.30 |

| Elongation (%) | 3.0-6.4 | 10-138 |

| Transparency (%) | 50-93 | 47-92 |

| Chemical Resistance | Poor – should only be cleaned with plastic cleaners or soapy water | Stronger than acrylic- can be cleaned with common detergents like ammonia. |

| UV Resistance | Good UV resistance – won’t degrade or discolor as easily | Lower resistance to UV rays – easily degrades over time unless additionally coated |

Optical Properties

1. Clarity

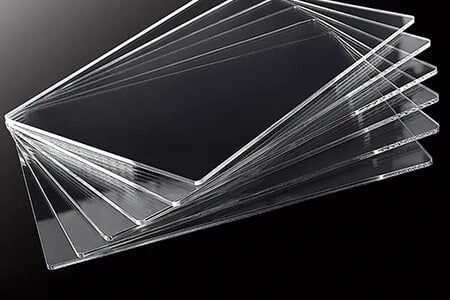

The two materials, acrylic and polycarbonate, are both available in clear, glass-like forms including recycled clear acrylic. Generally, acrylic has a higher light transmission rate than glass, with a rate of 92%. Polycarbonate, on the other hand, has a 88% light transmittance, as it is often treated for UV resistance due to its frequent use as roofing material.

As such, acrylic proves to be the ideal material for secondary glazing while polycarbonate is commonly used for constructing roofs in areas such as bus shelters and conservatories, thanks to its innate durability. If your acrylic material loses its clarity, you can restore it through polishing, whereas the same tactic cannot be applied to polycarbonate. This way, the polished acrylic material is given a shiny appearance.

Finally, both materials stand out as excellent substitutes for glass.

2. UV resistance

Acrylic sheets are more suitable for outdoor installations due to their superior performance against sun exposure. Their chemical composition makes them immune to UV rays, and they are less likely to deform or change color over time. Conversely, polycarbonate sheets require additional protection against sun rays, typically in the form of a UV-resistant coating applied to both sides. Moreover, they may develop a yellowish hue with prolonged sun exposure.

3. Scratching resistance

Polycarbonate may be more resilient than acrylic, but acrylic scores higher when it comes to scratch resistance. To compensate for the latter, polycarbonate eyeglass lenses are typically coated with an anti-scratch coating for added durability. Thus, acrylic is prone to cracking, whereas polycarbonate is easier to scratch.

Workability

The chart below compares the machinability of acrylic and polycarbonate:

| Process | Acrylic | Polycarbonate |

| Cutting | Can be cut using conventional tools, making the process easier but a higher risk of cracking when working with thinner sheets. | Can be cut using conventional tools but may resist the initial push of a saw or router. A low chance of it shattering during the cutting process. |

| Drilling/Machining | If drilled near the edge, it tends to crack. Require a plastic-specific drill bit. | When drilling near the edge of this material, it typically does not crack, allowing for regular drill bits. |

| Bending | Heat bending | Cold bending/ cold forming |

| Polishing | Can be polished | Cannot be polished, only buffed |

| Gluing | Cleaner glue joint than polycarbonate | The glue joint will not be as clean as acrylic |

Learn more about our CNC Machining Polycarbonate Capability

Cost

The cost of materials such as polycarbonate and acrylic can be lower than that of glass or other engineering materials. Polycarbonate is more expensive than acrylic since it offers better chemical resistance and durability. The average price per kilogram of polycarbonate sheet is about $2.50-3.50.

Acrylic shares many features with polycarbonate, such as transparency, toughness, and tensile strength. It also boasts a high-quality surface finish and is cheaper. On average, the cost per kilogram of acrylic sheet is around $1.50-2.00.

The pricing of these two materials is based on their form, thickness and grade. Typically, acrylic is cheaper than polycarbonate. However, working with acrylic can be more challenging as it is more likely to breakage.

Durability

Acrylic and polycarbonate are both able to withstand the effects of weather and changes in temperature without shrinking permanently.

Comparatively, polycarbonate is more impact-resistant than acrylic, making acrylic easier to chip. However, acrylic is less susceptible to scratching and will not discolor over time.

Polycarbonate is highly resistant to catching fire, while acrylic burns more slowly and should be avoided in areas where open flames may be present.

Sustainability & Recyclability

Both polycarbonate and acrylic are considered thermoplastic polymer materials, which makes them recyclable and re-processed in several ways. Although the quality decreases with every melting and molding, they still can go through the recycling process multiple times. Ultimately, these materials can be used as fillers for other plastics and in packaging.

As for sustainability, both polycarbonate and acrylic are manufactured using less heat and energy than producing an equal amount of glass. Moreover, polymer materials are simpler to recycle than glass, and their energy costs can be spread over many uses over their lifetime. Nevertheless, these materials must be disposed of and recycled appropriately to reduce their negative impact on the environment. Neither material decomposes over time, leading to a buildup in landfills or fragments ending up in waterways if discarded incorrectly.

Learn more about our CNC Machining Acrylic Capability

Substitutes to Polycarbonate and Acrylic

There are some alternative materials that could be considered for lightweight and fast-moving consumer goods that are cost-saving than polycarbonate or acrylic.

One such material is Polyethylene Terephthalate (PET), a translucent polymer widely used in water bottles, food containers, and other lightweight consumer goods. While PET may not be as transparent as polycarbonate or acrylic, it is still around 80% transparent, enough for many applications.

Another option is transparent Polyvinyl Chloride (PVC), which is known for its superior UV resistance and widely used for outdoor applications like lighting, windows, and seals.

Although glass is an alternative option that can provide a glass-like appearance, it is more expensive, difficult to process, heavier, and has a greater risk of shattering.

Conclusion

Polycarbonate and acrylic may look the same at face value but they’re different especially in their chemistry, costs, production possibilities, as well as the pros and cons of each. This is not necessarily why one product is better than the other but more about their features. Thus, this article aims to discuss the difference between these two materials so that you can choose the right product for your next project.

CNC Machining Expert for Custom Polycarbonate/Acrylic Parts|Runsom Precision

Both polycarbonate and acrylic are excellent alternatives to glass in CNC machining processes such as milling and turning. At Runsom, we offer CNC machining services to make polycarbonate or acrylic parts with high quality and low costs. Moreover, we provide a broad range of manufacturing capabilities and value-added services for all your prototyping and production requirements. Get an instant quote today.

Other Articles You May be Interested in: