Introduction

3D printing is the general team of multiple process, each technology has its benefits and limitations, so each 3D printing process is more suitable for special applications than others. We will apply some approaches to assist you to select the perfect way. We will analyze the technology selection form 3 different angles:

- Material requirement.

- Physical or visual characteristics.

- Technology capability like accuracy, parts size.

Technology Selection by Material

3D printing materials are normal form in filament, powder to resin, which depends on the actual 3D printing process. Polymers and metal are two main 3D printing materials, other materials including ceramics and composites. Polymers are also including thermoplastics and thermosets.

Once required materials is confirmed, the selection of 3D printing process is easy, in reason of just a few technologies apply the same materials. So we just need compare the cost and properties, and select the most cost-effective 3D printing technologies.

Thermoplastics

Thermoplastics are the most suitable materials for functional applications, including end-use parts and functional prototypes. These materials have excellent mechanical properties, high impact resistance, high abrasion and chemical resistance. We also can add carbon, glass or other additives in thermoplastics to enhance final physical properties. Engineering thermoplastics like Nylon, PEI and AS are widely applied to produce industrial applications parts.

SLS can produce better mechanical and physical properties parts with higher dimensional accuracy. However, FDM is a more economical technology with less leading time.

As our experience of thermoplastic materials in 3D printing, the better of materials mechanical properties, the harder to produce with higher cost.

Thermosets

Thermosets or resins are more suitable for parts with aesthetic requirement, these materials can produce parts with injection-like smooth surface and fine details. Normally, thermosets have high stiffness while are more brittle than thermoplastics. So there materials are not suitable for functional applications. MJF can produce parts with higher dimension accuracy and smoother surfaces, but the cost will be higher than SLA. Both two technologies apply similar potocurable resins.

| 3D Printing Technology | Materials |

| MJF | Standard resinTough resin (ABS-like)Durable resin (PP-like)Clear resinDental resin |

| SLA | Standard resinTough resin (ABS-like)Durable resin (PP-like)Clear resinDental resin |

Metals

Metal 3D printing parts have excellent mechanical properties, which can operate normally at high temperatures. This encourage them to be the most ideal technology for lightweight applications in aerospace and medical industries. DMLS parts have superior mechanical properties and tolerances, while Binder Jetting is more cheaper, and also can produce larger parts.

| 3D Printing Technology | Materials |

| DMLS | Stainless steelTitaniumAluminum |

| Binder Jetting | Stainless steel |

Other materials

Since materials like ceramics and sandstone is not widely applied, their application are limited. The only available technology is Binder Jetting.

| 3D Printing Technology | Materials |

| Binder Jetting | Ceramic |

Technology Selection by Application

Once function or visual appearance become the main design consideration in 3D printing, we should focus on choosing the most suitable process, which is the most important element to determine the selection process. As in our experience, thermoplastic polymers are more suitable for functional applications while thermosets are better suited for visual appearance.

Functionality

We will provide for you to identify the most suitable 3D printing process, which are based on design requirement for functions.

| Functionality | Tolerance | Low (±0.5mm) | FDM |

| Medium (±0.3mm) | SLS | ||

| High (±0.1mm) | MJFSLA | ||

| High strength | Low (< 30MPa) | FDM | |

| Medium (30-85MPa) | SLS | ||

| High (> 85MPa) | DMLSBinder JettingFDM | ||

| Special properties | Chemical resistance | SLS | |

| Heat resistance | SLSSLA | ||

| Bio-compatible | DMLSFDMSLA | ||

| Flexible | High elongation | FDMSLS | |

| Soft/Rubber-like | MJFSLA |

In addition, we also recommend some information as following:

- Once design parts that will interfere with other components, we should define the necessary level of tolerances. However, higher dimensional accuracy will increase the cost. Alternative options is to finish features with critical dimensions or small details after 3D printing process.

- The overall part strength depends on different mechanical and physical properties. We can use the tensile strength as guidance of selection, in order to simplify the selection. For high strength and stiffness, DMLS or FDM with continuous carbon fibers are the perfect selection.

- Engineering materials have special properties, like heat resistance, chemical resistance, or Bio-compatibility.

- Flexibility is the high elongation at break, there is TUP available in SLS and FDM.

Visual appearance

Once visual appearance is the main concern of our 3D printing parts, we can select the most suitable technology by the following chart.

| Visual appearance | Smooth surface | Support marks | SLA |

| No support marks | MJF | ||

| Transparent | Support marks | SLA | |

| No support marks | MJF | ||

| Texture | Wood-fill | FDM | |

| Metal-fill | FDM | ||

| Full color | Polymer | MJF | |

| Sand | Binder Jetting |

In addition, we also recommend some information as following:

- Both SLA and MJF are able to produce parts with smooth and injection-molding like surface. The main difference of these two technologies is support structures, MJF support is soluble, while SLA support need to be removed manually.

- MJF can produce fully transparent parts, while SLA only can produce semi-transparent parts, which can be post-processed to 100% optically clear.

- Special texture as wood-like or metal-like can be produced by wood-fill or metal-fill FDM filaments. Rubber-like parts are soft, which can be bend and compress, but lack of performance of true rubber.

- MJF and Binder Jetting can provide full-color printing capabilities. MJF also can offer materials with better physical properties and multi-material capability.

Technology Selection by Manufacturing Capabilities

Once 3D printing design is finished, the manufacturing capabilities of each technology will determine the final selection process. It is critical to overview the fundamental mechanic of each technology, and fully understand the key benefits and limitations.

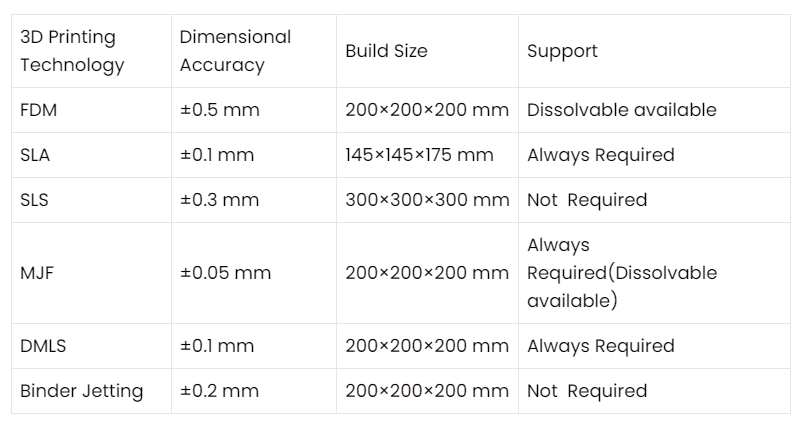

There are some rules to interpret the following data:

- Dimensional accuracy determines the feature details and parts quality. Process with higher accuracy will create finer features.

- Build size determines the parts maximum dimensions. For exceeded build size parts, we should consider split part into multiple components and assembly later.

- Support structure determines the level of design freedom. Technologies with no support like SLS, or dissolvable support like MJF, or dual-extrusion like FDM, have few limitations. Which can produce more free-form structures.

| 3D Printing Technology | Dimensional Accuracy | Build Size | Support |

| FDM | ±0.5 mm | 200×200×200 mm | Dissolvable available |

| SLA | ±0.1 mm | 145×145×175 mm | Always Required |

| SLS | ±0.3 mm | 300×300×300 mm | Not Required |

| MJF | ±0.05 mm | 200×200×200 mm | Always Required(Dissolvable available) |

| DMLS | ±0.1 mm | 200×200×200 mm | Always Required |

| Binder Jetting | ±0.2 mm | 200×200×200 mm | Not Required |

Layer height

Layer height is another important element we should consider in technology selection. In reason of 3D printing additive nature, layer height determines the surface smoothness and minimum features size. The smaller layer height will decrease the stair stepping effect and produce more accurate surface.

| 3D Printing Technology | Typical Layer height |

| FDM | 50-400 microns |

| SLA | 25-100 microns |

| SLS | 80-120 microns |

| MJF | 16-30 microns |

| DMLS | 30-50 microns |

| Binder Jetting | 100 microns |

Conclusion

We should confirm whether functionality or visual appearance is the the first priority in early selection process. Once confirm the material, a cost versus properties comparison is the main point of selection process. If you are interesting in our professional 3D technology, contact our engineering team now.