China CNC Machining Manufacturer of OEM Automotive and Motorcycle Parts

The development of the automotive and motorcycle industry relies on automotive parts processing, motorcycle parts production, and automobile parts prototype making. Moving forward, the automobile industry is expected to be focused on electric energy-saving, self-driving technology, and shared internet capabilities, with constant updates each year. With global economic integration, international auto R&D companies and manufacturers are streamlining their supply chains and controlling production costs. As a result, certain aspects of auto parts procurement, auto parts machining, motorcycle parts production, and automobile parts prototyping are being outsourced to China. In the future, China will offer more support services to the global automotive industry. Since 2005, Runsom Precision has been providing customers with customized automobile and motorcycle parts machining and prototyping services, assisting in the advancement of the automotive and motorcycle industry.

When it comes to custom automotive parts processing, motorcycle parts production, and auto parts prototype making, multiple processes are usually required. This typically involves CNC machining, as well as boring, milling, and grinding processing to achieve tight tolerance up to +/- 0.005mm and surface finish up to Ra 0.8.

Our Capability on CNC Auto and Motorcycle Parts Machining

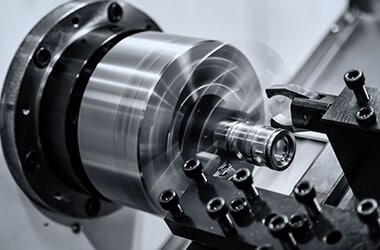

With our state-of-the-art CNC Swiss lathes and ultra-precision 3, 4, and 5-axis CNC machine centers, Runsom Precision is your go-to manufacturing partner for precise auto and motorcycle components. We recognize the automotive industry's need for cutting-edge technologies to make high-quality parts, and our advanced equipment ensures that we deliver nothing short of excellence.

Precision CNC turned parts at the most competitive pricing, with fast lead times, and without requirements for minimum order quantity. The instant manufacturability feedback offered by Runsom’s professional technological team allows us to optimize your part designs for the CNC turning process and fulfill all requirements you need. Learn more...

Runsom has competitive markets in complex part manufacturing with ultra-precision 5-axis CNC machining with decades of incomparable innovation and experience. We are experts in true 5-axis machining, which enables us to quickly produce "almost impossible to make" 5-axis parts. Learn more...

Swiss CNC machining is a specialized process to machine small, high-precision turned parts. Precision Swiss CNC machining services are our specialty at Runsom. We can offer you suitable cost-effective solutions in Swiss-type machining and produce high-quality precision-turned parts. Learn more...

Materials and Surface Finishes for Auto and Motorcycle Parts

We offer a multitude of materials and post-processing operations for your choice to help you get the desired automobile parts, auto and motorcycle prototypes.

Materials

Surface Finishes

Post-processing operations are often required after the machining of motorcycle and automobile parts. These processes significantly enhance the specific properties of these machined parts, including both their functionality and visual appeal. Consider the following common surface finishes that are available for the motorcycle and car parts we provide:

Custom Your CNC Automotive Parts at Runsom Precision

CNC Auto Steering Knuckle

CNC Auto Wheel Hub Bearing

CNC Auto Oil Dipstick

CNC Auto Hub Adapter

CNC Auto Clutch Basket

CNC Auto Drive Housing

Custom Your CNC Motorcycle Parts at Runsom Precision

CNC Motorcycle Radiator Guard

CNC Mini Motorcycle Part

CNC Motorcycle Handlebar Risers

CNC Motorcycle Wheel Hub

CNC Motorcycle Rear Sprocket

CNC Motorcycle Wheel Axle Sliders

Ready to Get Custom Precision Parts for Your Automobiles or Motorcycles?

With over 10 years of experience serving the automotive and motorcycle industry, Runsom Precision is a reliable provider of OEM services. We specialize in the manufacturing of high-quality car components and motorcycle accessories that exceed our customers' expectations. Our extensive knowledge of the manufacturing process allows us to deliver custom precision components with tolerances as tight as +/- 0.010 inches. Whether it's short-run production, volume production, or prototyping, we have the capability to meet the high demands of the auto and motorcycle industries. Partner with us for unparalleled quality and service you can rely on.

Why Use CNC Machining for Auto and Motorcycle Parts Making?

CNC machining is an essential process in the prototyping and production of automotive and motorcycle parts. It enables manufacturers to create prototypes to identify and rectify design flaws before actual production. Manufacturers can ensure the quality and functionality of the parts in accordance with design requirements. It's ideal for the real production of these parts as well.

The demands in the automotive industry are increasingly growing. With millions of cars being manufactured annually, the production process requires numerous specialized parts that need to be accurately fitted together. As a result, machining equipment used for producing automobile parts must meet the industry's high demands for both large-volume production and extremely tight tolerances. CNC automotive machining encompasses various operations like CNC milling, turning, and drilling. These work effectively with metals, plastics, and composites, allowing for the creation of intricate car components due to their repeatability, precision, and accuracy.

CNC machining offers multiple machining processes and exhibits remarkable versatility to cater to the rigorous requirements of the motorcycle and automotive industries, allowing for the processing of various metal materials and other materials such as wood, plastic, ceramic, and composites.

CNC machining is well-suited for both motorcycle manufacturers and enthusiasts to get custom parts. It allows for the design and customization of the parts based on their preferences, whether it involves color, engraving, or functionality.

Moreover, CNC machining is particularly useful for replacing damaged parts. Motorcycle components are prone to damage in the event of even minor accidents, such as scratches, crushing, or abrasions against the pavement. In such cases, CNC machining offers the best solution for creating and customizing single or multiple replacement parts as needed.

Applications of CNC Machined Automobile and Motorcycle Parts

Commonly Machined Automotive Parts

Commonly Machined Motorcycle Parts

Precision Machining and Prototyping: Your Auto and Motorcycle Parts with Runsom Precision

As an ISO 9001:2015 certified manufacturer, Runsom Precision serves automotive and motorcycle customers worldwide, including Germany, Japan, the United States, and various European and Asian countries. Our extensive range of services includes car parts machining, motorcycle parts production, and custom auto prototype customization. Equipped with advanced machining equipment like 5-axis machine centers and CNC Swiss lathes, our experienced experts can fulfill your needs for both prototype customization and volume production. At Runsom Precision, we prioritize quality and strictly adhere to ISO 9001:2015 quality management system standards throughout each production process. Upload your 3D files online for an instant quote and experience our unrivaled machining capabilities.