Orthopedic implants, as outstanding representatives of modern medical technology, are playing an increasingly important role in the field of orthopedic disease treatment. They can effectively repair damaged bones and joints, helping patients regain health and vitality. This article will delve into the application of orthopedic implants in the medical industry.

Orthopedic Implants and Their Significance

Orthopedic implants refer to medical devices used to replace or assist in the treatment of orthopedic diseases affecting bones, joints, muscles, ligaments, etc. Typically made from medical-grade metals, plastics, ceramics, and other materials, these implants aim to repair, replace, or support the skeletal structure to restore or maintain its normal function. Overall, the use of orthopedic implants in the medical industry enhances treatment efficiency reduces medical costs, and improves patients’ quality of life and satisfaction. Therefore, orthopedic implants are undoubtedly an essential component of modern medical technology and a key direction for future developments in the healthcare industry.

Types of Orthopedic Implants

Metal Implants

Metal implants, including nails, and plates made of materials such as titanium alloys, stainless steel, and tungsten steel, are known for their high strength and stability. They are commonly used to support and stabilize fracture sites, promoting bone healing.

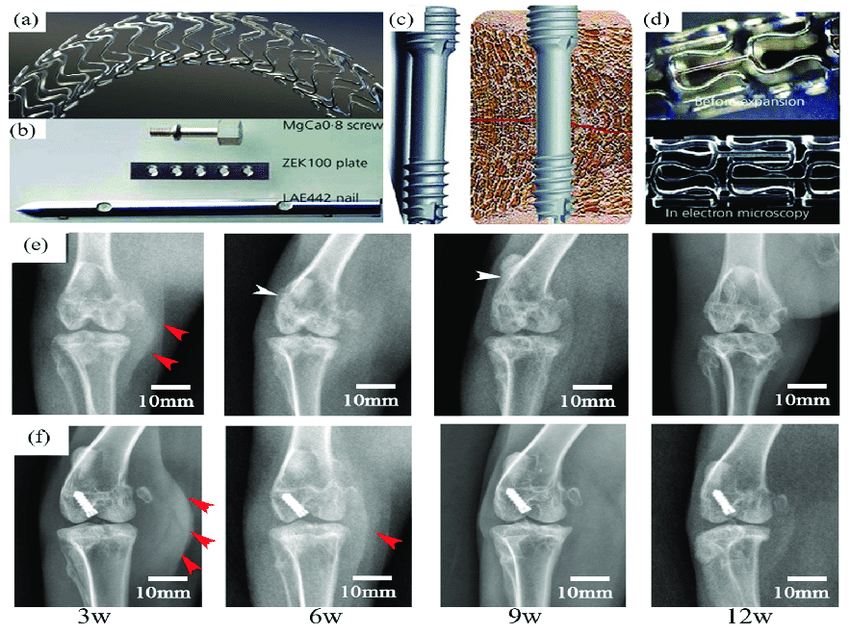

Biodegradable Implants

Made from biological materials like biodegradable polymers such as PLA, and PGA, these implants can gradually degrade and integrate with surrounding tissues, reducing the risk of secondary surgeries. They are particularly suitable for bone injuries and reconstruction.

Bone Cement

Primarily, PMMA (polymethylmethacrylate) implants are used to fill bone cavities and support vertebrae, providing excellent fixation and durability. They are commonly used in vertebral augmentation surgeries.

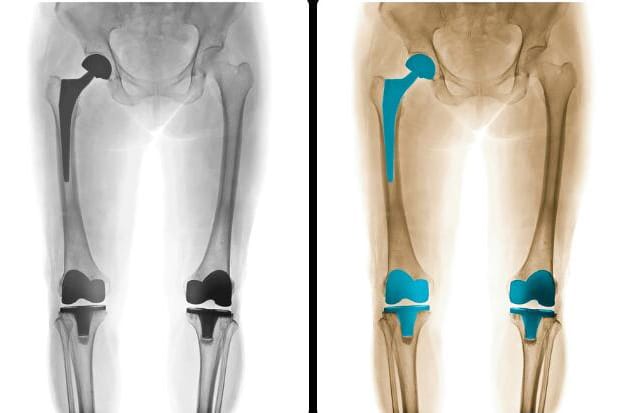

Artificial Joint Implants

These include artificial hip joints, and knee joints, which mimic the structure and function of natural joints, alleviating joint pain and improving patients’ mobility.

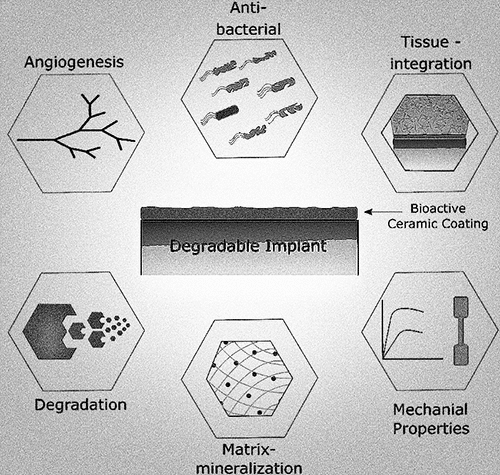

Bioactive Implants

Involving growth factors, and cell cultures, these implants promote bone regeneration and repair, accelerating the healing process, and playing a vital role in bone defects and repair.

Bone Grafts

Bone tissue from the patient’s own body (autograft) or a donor (allograft) is used to reconstruct bone defects and promote healing. Autografts reduce rejection risks, while allografts have a faster integration speed.

Application of Orthopedic Implants in Different Diseases

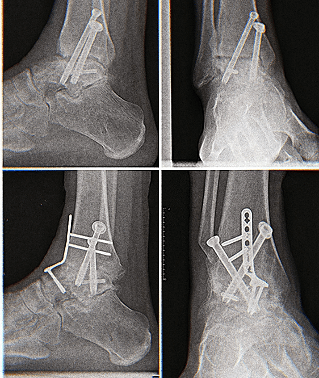

Fracture Treatment

For example, metal implants such as steel plates, intramedullary nails, etc., are used to fix and support fracture sites, promoting bone healing.

Joint Replacement

In joint replacement surgeries, orthopedic implants like artificial hips, knees, etc., are employed to replace diseased or damaged joints. These artificial joints can mimic the structure and function of natural joints, providing significant benefits for treating severe conditions like arthritis, avascular necrosis of the femoral head, etc.

Spinal Treatment

In spinal treatments, orthopedic implants such as pedicle screws, interbody fusion devices, etc., are utilized to stabilize and support the spine, correct spinal deformities, alleviate nerve compression and significantly improve conditions like scoliosis, lumbar disc herniation, etc.

Osteoporosis

Orthopedic implants can prevent and treat fractures caused by osteoporosis. For example, absorbable implants can gradually dissolve inside the body, reducing the need for secondary surgeries.

Bone Tumors

Patients with bone tumors may require partial or complete bone resection surgeries, necessitating the use of orthopedic implants to reconstruct the bone structure and restore its function.

The Safety of Orthopedic Implants in MRI

The safety of orthopedic implants in magnetic resonance imaging (MRI) is influenced by several key factors:

Material Selection

The choice of materials used in implants is crucial for their performance in MRI. Typically, stainless steel, titanium alloys, and similar materials have minimal impact on the MRI magnetic field and are relatively safe. On the other hand, magnetic materials like nickel, iron, etc., may be attracted by the magnetic field or generate local heating, posing potential risks.

Magnetic Effects

If implants are magnetic, they may experience attraction or local heating during MRI, increasing the risk for patients. Therefore, MRI safety can vary based on the magnetic properties of the implants.

Manufacturer Information

Manufacturers usually provide information on the MRI safety of implants. Healthcare professionals should carefully understand and adhere to this information to ensure patient safety during MRI.

Magnetic Field Strength

The magnetic field strength of the MRI equipment can also affect how implants behave during MRI. Higher magnetic field strengths may increase the risk of interference with implants.

Selection and Machining of Orthopedic Implant Materials

Principles for the Selection of Implant Materials

1. Biocompatibility: The material must be compatible with human tissues to reduce the risk of rejection reactions and tissue damage.

2. Mechanical Performance: Implants need to possess sufficient mechanical strength and toughness to withstand the loads within the human body.

3. Durability: Implants should maintain their performance and integrity over long-term use.

4. Corrosion Resistance: Materials should exhibit good stability against corrosion and fatigue in the biological environment.

5. Cost-Effectiveness: The cost of materials should be reasonable to ensure the economic viability of implants.

6. MRI Safety: If the implant may require an MRI examination, the selection of materials safe for the MRI environment should be considered.

Common Implant Materials

Common implant materials include titanium alloys, stainless steel, polyethylene, polytetrafluoroethylene, etc. Titanium alloy has become a commonly used orthopedic implant material due to its high biocompatibility, lightweight, and excellent mechanical properties.

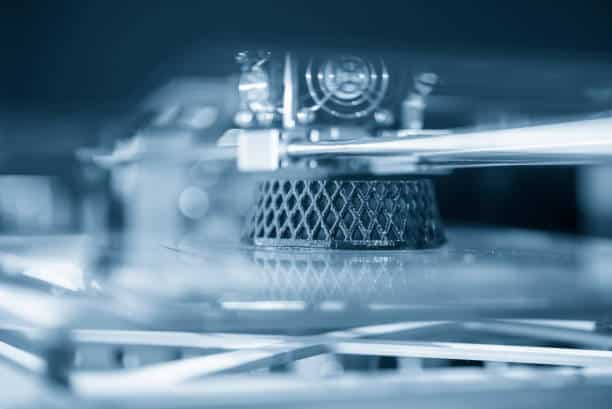

Advanced Manufacturing Processes and Technologies

1. Additive Manufacturing Technology: This includes 3D printing and selective laser sintering, which can customize implants according to the patient’s specific anatomical structure, improving the fit and match with surrounding bone tissue.

2. Surface Treatment: Techniques such as sandblasting, acid etching, and anodizing improve the surface quality and biocompatibility of materials.

3. Biological Activity Coating: Hydrophobic coatings, drug-releasing coatings, etc., can help improve the biocompatibility and healing speed of the implant with surrounding bone tissue.

Custom Orthopedic Implant Manufacturer – Runsom Precision

When considering a partner for manufacturing custom orthopedic implants, Runsom Precision is a notable choice. The company has rich experience in CNC machining and the biomedical device field, providing professional custom orthopedic implant services. With advanced manufacturing technology and strict quality control processes, Runsom Precision can meet the personalized medical needs of clients, ensure products meet high standards, and align with customer expectations. Choosing Rich Precision as a partner will facilitate obtaining high-quality custom orthopedic implants, meeting specific medical implant needs, and promoting innovative development. Feel free to contact us for a quote and more information at any time.

Other Articles You Might Enjoy: