Surgical instruments play a pivotal role in the medical industry, serving as indispensable tools for surgical procedures. This article delves into the various aspects of surgical instruments, including their applications, manufacturing materials, common types, sterilization, processing techniques, and more. Understanding the relevant knowledge about surgical instruments contributes to a deeper understanding for healthcare professionals and patients, enhancing operational safety and surgical outcomes.

Surgical Instruments with Names

| Forceps | Scissors | Clamp |

| Suture | Bone Saw | Speculum |

| Poole Suction | Retractors | Surgical drill |

| Hemostats | Curette | Scalpel |

| Needle Holder | Retractor | Electrocautery |

What are Surgical Instruments Made of?

Surgical instruments are typically made from a variety of materials based on their specific use and characteristics. Here are some common raw materials used in manufacturing surgical instruments:

Stainless Steel

Stainless steel is a commonly used material for surgical instruments due to its corrosion resistance, durability, and ease of cleaning.

Medical Grade Plastics

Such as syringes, and contrast media tools, meeting medical hygiene standards and being harmless to human tissues.

Titanium Alloys

Titanium alloys find extensive application in surgical instrument manufacturing due to their high strength, lightweight, and biocompatibility, especially in heavy-duty and orthopedic instruments.

Glass

Glass materials are employed in some ophthalmic surgical instruments like corneal cutting knives.

Polycarbonate

Polycarbonate materials with high transparency and strength are commonly used in manufacturing retinal surgical instruments.

Titanium

Titanium exhibits high strength, excellent biocompatibility, and corrosion resistance, making it common in orthopedic surgical instruments.

Applications of Surgical Instruments

In the medical field, surgical instruments have broad applications, some of which include:

Obstetric Surgical Instruments

Specifically designed for cesarean section surgeries, these instruments include cesarean section knives, surgical forceps, and suturing materials facilitating smooth cesarean section procedures.

Plastic Surgery Instruments

Primarily used in various plastic surgery procedures like rhinoplasty, breast augmentation, liposuction, and common instruments include plastic surgery knives, various needles, and liposuction equipment.

Ophthalmic Surgical Instruments

Encompassing a range of instruments for eye surgeries such as ophthalmic knives, corneal transplant tools, and eye surgery forceps used in procedures like cataract surgery, corneal transplants, and refractive surgeries.

Abdominal Surgical Instruments

Employed in various abdominal surgeries including gastrointestinal procedures, hepatic-biliary-pancreatic surgeries, and laparoscopic surgeries, common tools include scalpels, scissors, various clamps, and suturing devices.

Dilating Surgical Instruments

Including dilators and separators, these instruments facilitate the expansion and positioning of tissues or organs during surgery for precise operative maneuvers.

How are Surgical Instruments Sterilized?

Steam or autoclave sterilization is one of the most common methods used to ensure the sterility of surgical instruments. Here are more detailed insights into this method:

Steam or Autoclave Sterilization

This method involves exposing the instruments to high temperature and pressure in moist steam, killing and removing bacteria, viruses, and spores to maintain the sterility of the instruments. It is an efficient and commonly used sterilization method in medical institutions and operating rooms.

Sterilization Indicators

Sterilization indicators such as autoclave tapes or indicator strips are essential. These indicators are employed during instrument packaging to identify sterilized instruments. Upon exposure to the steam sterilization process, indicators display specific colors, symbols, or marks to indicate that the instruments have undergone proper sterilization treatment.

Equipping sterilization indicators enables healthcare professionals to easily identify sterilized instruments, effectively ensuring the sterility of surgical instruments, while complying with medical hygiene standards and procedures.

Machining Techniques for Surgical Instruments

The processing techniques for surgical instruments are crucial as they directly impact the precision, material characteristics, and the final product’s quality. Here are common processing techniques for surgical instruments:

Milling

A common machining process where material is removed using rotating cutting tools to achieve the desired shape and size. For surgical instruments, precise dimensions and surface quality are crucial.

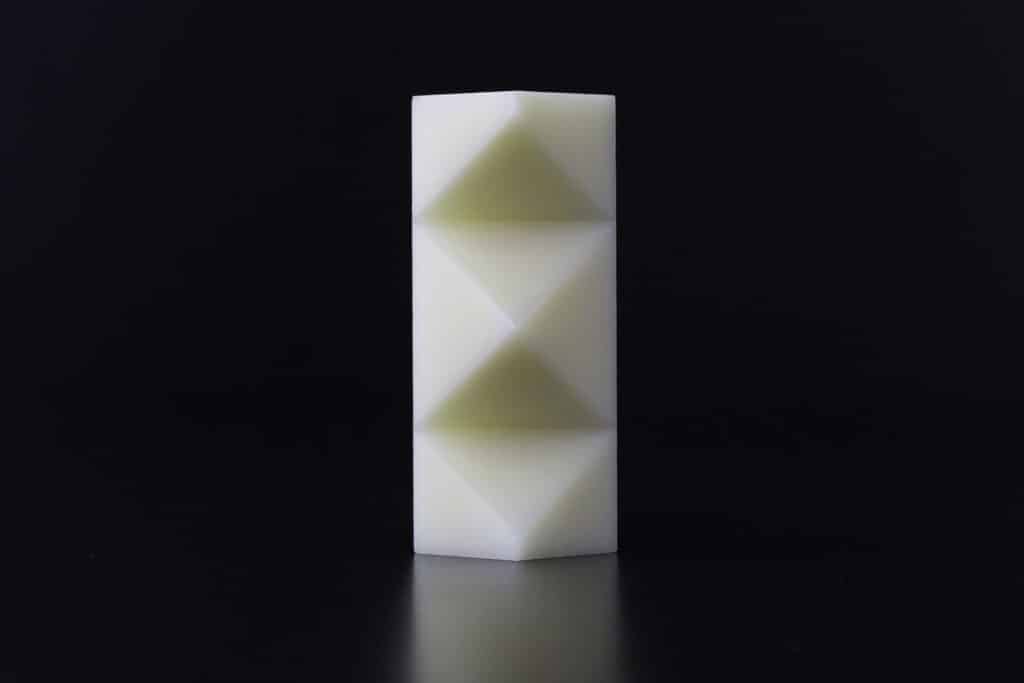

Precision Machining

Includes techniques like CNC machining, wire cutting, and electrical discharge machining, capable of achieving high-precision processing of complex shapes and structures of instruments ensuring functional and aesthetic requirements.

Grinding

Often utilized to improve the surface quality and dimensional accuracy of workpieces. For components of surgical instruments requiring special shapes and high precision, grinding is an indispensable processing technique.

Includes processes like quenching, tempering, and carburizing, used to adjust the material’s hardness, toughness, and corrosion resistance ensuring excellent performance of surgical instruments.

Involves processes like polishing, coating, and anodizing, to enhance the surface smoothness, corrosion resistance, and biocompatibility of surgical instruments.

Future Development Direction of Surgical Instruments

The future direction of surgical instruments includes the application of innovative materials, integration of smart technologies, miniaturization, and personalized customization of surgical instruments. With the continuous advancement of technology, the application of technologies such as cancer treatment, robot-assisted surgery, and 3D printing will influence the future development direction of surgical instruments. Highly intelligent and digitized surgical instruments will provide healthcare professionals with more precise and safer surgical operating experiences.

Conclusion

Surgical instruments, as critical tools in the medical industry, have a wide range of types and applications. With ongoing advancements in medical technology and processes, surgical instruments continue to innovate and improve to meet the needs of different surgeries, enhancing surgical safety and precision. Understanding surgical instruments in depth benefits healthcare professionals and patients undergoing surgery by addressing challenges during the surgical process, ensuring smooth operations and patient safety.

When choosing Runsom Precision to customize Surgical instruments, you can rely on its rich professional experience, the use of high-quality materials and CNC machining technology, as well as strict quality control processes to ensure that the produced parts meet the industry standards of medical devices and your personalized requirements. Runsom Precision’s meticulous service and professional engineering team can also ensure full communication with customers, making the process of customizing surgical instruments smooth, efficient, and ultimately meeting customer expectations. Feel free to obtain an instant quotation at any time so that you can promptly understand the cost of the customized service.