Dental instruments are tools and equipment used to diagnose, treat, and prevent oral diseases. They are utilized in dental clinics and laboratories to provide a wide range of dental treatment services, including dental examinations, scaling, fillings, dental care, and various dental procedures. Simultaneously, dental instruments are reliable assistants of dental practitioners in daily diagnosis and treatment activities and a key factor in ensuring patients’ oral health.

This article aims to delve into the types, characteristics, materials, disinfection methods, and CNC manufacturing processes of dental instruments.

Types of Dental Instruments

Precise dental instruments have various types and characteristics.

Oral Examination Instruments

- Mouth Mirror: A Smooth surface and appropriate curvature provide a clear view inside the oral cavity.

- Explorer: Blunted tip and slender design for detecting subgingival calculus and periodontal pockets.

Dental Treatment Instruments

- Dental Drills: High speed, low noise, and low vibration, ensuring precision and comfort during tooth restoration and treatment.

- Dental Filling Materials: Excellent malleability and adhesion, enabling seamless integration with natural teeth.

Dental Surgery Instruments

- Dental Surgical Blades: Precision blade design and comfortable handle ensure surgical accuracy and safety.

Imaging and Auxiliary Instruments

- Digital X-ray Machine: High-definition imaging capability and low radiation dosage ensure accurate diagnosis and treatment planning.

These instruments are precision-designed and manufactured to ensure their efficiency, safety, and comfort, thus improving the success rate of dental treatments and the overall patient experience.

Materials of Dental Instruments

Dental instruments are typically made from various materials, each with specific characteristics and advantages suitable for different instrument purposes. Here are some common materials used for manufacturing dental instruments:

- Stainless Steel: Stainless steel is one of the most common materials for dental instruments, known for its excellent corrosion resistance and durability. Its high hardness allows for easy sterilization and cleaning, making it suitable for manufacturing instruments such as forceps and tweezers.

- Tungsten Steel: Tungsten steel offers higher hardness and wear resistance, suitable for manufacturing precision dental drill bits and other high-precision, wear-resistant instruments.

- Ceramics: Ceramics are widely used in the dental field due to their excellent corrosion resistance, oxidation resistance, and non-magnetism. They are commonly used in manufacturing dental surgical blades and some high-temperature, high-pressure resistant instruments.

- Plastic: Plastic is often used for manufacturing handles or grip parts to improve user comfort and reduce patient discomfort. Lightweight, easy to clean, and cost-effective, suitable for some oral examination instruments, among others.

- Alloys: Alloys, as mixtures of multiple metallic elements, offer excellent strength and corrosion resistance. They can be used for manufacturing special dental surgical instruments requiring strength and wear resistance.

- Silicone: Silicone is commonly used in manufacturing soft dental hygiene products, dental braces, and other soft instruments, valued for their flexibility and durability.

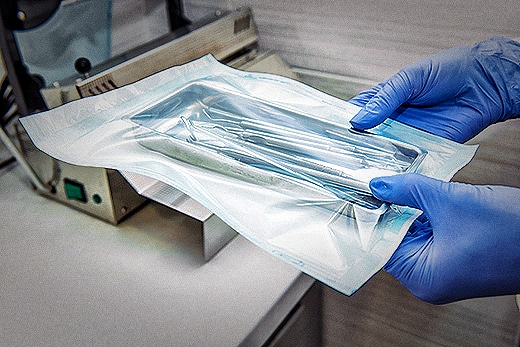

Methods of Sterilization for Dental Instruments

1. Heat Sterilization (Autoclaving):

This is a common and effective method of disinfection that uses high-temperature and pressure steam to kill bacteria, viruses, and fungi.

2. Chemical Disinfection:

Chemical disinfectants such as hydrogen peroxide, vinegar, and ether-based disinfectants can be used for soaking dental instruments for disinfection.

3. Ultrasonic Cleaning:

This method utilizes ultrasonic vibrations to clean the surfaces of instruments and is often used in conjunction with chemical disinfection to remove debris and microorganisms attached to the instrument surfaces thoroughly.

4. Cold Disinfectant Solutions:

In certain special cases where specific instrument materials are temperature-sensitive, cold disinfectant solutions are used for disinfection purposes.

Processing Techniques of Dental Instruments

1. Design Planning:

Initial product design planning is necessary, including specifying the instrument’s exact specifications, structure, and functional requirements. Design engineers use Computer-Aided Design (CAD) software to create precise instrument design drawings.

2. Material Preparation:

Select appropriate materials based on design requirements, which may involve materials such as stainless steel, tungsten steel, and ceramics, among others. These materials undergo precise manufacturing processes to ensure they meet strict standards.

3. CNC Machining:

Utilize CNC machines for milling, turning, drilling, etc., to machine raw materials into precise instrument components according to design specifications. These processes require highly precise and fixed machining techniques.

4. Heat Treatment:

Apply heat treatment to some materials to ensure they possess the required hardness, strength, and wear resistance. This ensures the mechanical performance needed for the instruments.

5. Quality Control:

Throughout the manufacturing process, quality control is crucial to ensure each instrument meets precise specifications and standards. Various inspection equipment and techniques are used for rigorous testing to ensure the instruments meet design requirements.

6. Surface Treatment:

Lastly, the instruments undergo surface treatment, which may include polishing, edge rounding, and cleaning processes to ensure the instruments’ surfaces are smooth, sterile, and meet hygiene requirements.

Precision Dental Instrument Manufacturer – Runsom Precision

Runsom Precision is a company specializing in precision instrument manufacturing with rich experience and expertise in the dental industry. By employing high-precision machining equipment and advanced processes, Runsom Precision is dedicated to producing precision components. Combining a strict quality control system and excellent heat treatment process ensures the dental instruments manufactured have the required hardness, corrosion resistance, and precision. Feel free to contact us for quotes and more detailed information.

Conclusion

In conclusion, dental instruments play an irreplaceable role in the field of oral healthcare. Understanding the types, characteristics, materials, disinfection methods, and precision manufacturing processes of dental instruments is essential for enhancing the standards of oral healthcare and ensuring patient safety.

Other Articles You Might Enjoy: