Having a set of machinist tools is essential for any machinist, fabricator, or technician involved in manufacturing. However, with a plethora of tools on the market, it’s crucial to select the most effective and efficient ones for optimal productivity. Thus, it’s vital to have a fundamental knowledge of the basic tools and know how to choose and apply the ideal tool for the job or create a customized toolbox tailored to individual needs.

This article will discuss the most frequently used machinist tools for CNC machine shops, which will be divided into four categories for easy access. Each category will include vital and relevant tools.

Measuring Tools

This section features a collection of crucial measuring equipment within the machine tools category. Here are some examples of important items to consider:

Micrometers

A micrometer, also known as a micrometer screw gauge, is useful for measuring the diameter, thickness, and length of objects accurately. There are various types of micrometers, including digital, dial, and vernier, with different prices. A digital micrometer is more useful since it minimizes the risk of reading errors. It’s crucial to pick the right size for your project and budget. If you have a non-digital micrometer screw gauge, you can learn how to use it by clicking this link.

Calipers

For beginners in machining, the caliper is an essential measuring tool. It accurately measures the distance between two opposite points on an object. To use the caliper, place the tips on the measuring points, remove them, and then measure the distance between the tips, without using additional tools.

Calipers come in various types, some with added features like reading measurement scales, dials or digital displays. Choose between the dial and digital caliper based on your preferences. Proper storage is critical for maintaining their precision.

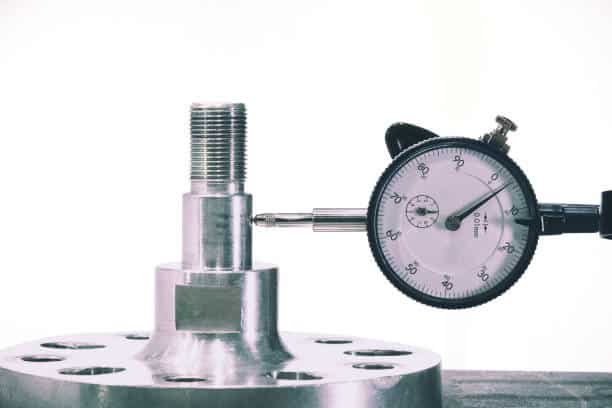

Dial Indicators

The dial indicator is one of the various measuring tools utilized by machinists during machining tasks. It features a clock-like display that helps measure minute linear distances. The tool’s versatility is limitless, as it proves helpful in measuring deck clearances, crankshaft thrust, and ensuring the vice is perfectly squared with the machine axis.

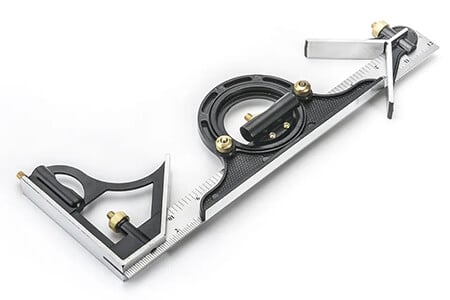

Combination Square Set

A combination square, which is also referred to as a combination square set, consists of a ruler and various attachable heads, with the standard or square head being the most commonly used one. This head is ideal for verifying or creating precise 45° and right angles. This versatile tool is commonly used for measuring angles and lengths in machining.

Edge Finders

As an affordable and practical piece of instrument, an edge finder is a great addition to any machinist’s toolkit. It may not be compulsory, but its usefulness and low cost make it an excellent aid for aligning tools and achieving an optimal position.

Coordinate Measuring Machine

CMM (Coordinate Measuring Machine) is a device used in CNC machine shops to measure the geometric characteristics of a variety of materials, components, and objects to ensure the accuracy and quality of manufactured products. It uses a probing system to touch or scan the object to create a detailed 3D map of its surface, which can then be analyzed by specialized software for further analysis and measurements. Nowadays, it’s viewed as a necessary investment for any facility striving to produce high-quality products.

Roughness Testers

Roughness testers, also known as surface roughness testers, are measurement tools used to evaluate the roughness of a material’s surface. They are vital machine shop tools as they help ensure that the finished products meet specific roughness requirements. Roughness testers typically come in two types: contact and non-contact.

- Contact type roughness testers – using a stylus that comes into contact with the surface of the workpiece, and the stylus movement is converted into an electrical signal that is used to measure the roughness. These testers are highly accurate but can potentially damage delicate or soft surfaces.

- Non-contact type roughness testers – using laser or white light interferometry to measure surface roughness without physically touching the surface. These testers are high precision and can be used on delicate and sensitive surfaces but are generally more expensive than contact testers.

Gage

- Telescoping gauge – used to measure the internal dimensions of an object.

- Radius gauge set – designed to measure the radius or curvature of an object.

- Center gauge – consists of a small rod with two pointed ends, and a ruler that is perpendicular to the rod, used to find the center of a cylindrical object.

- Feeler gauge – a thin, flat gauge consisting of metal strips of varying thicknesses to measure small gaps or clearance between two surfaces.

- 1” gauge block – a square-shaped block with a thickness of exactly 1 inch (25.4mm) and made of high-grade steel or ceramic materials, used for calibrating and verifying the accuracy of other measuring instruments such as micrometers, dial indicators and height gauges.

Abrasives

Abrasives are utilized to refine and polish a variety of materials, including metal, plastic, and wood, helping to enhance efficiency, accuracy, durability, and safety in the machining process, they play an important role. These are some recommended tools:

Grinding Wheels

Grinding wheels are made up of abrasive grains and a bonding agent, which holds the grains together. They are abrasive cutting tools that use grains of abrasive material to establish cutting action on the workpiece.

The size of grinding wheels ranges from small handheld grinder wheels to large bench grinders, and their geometries vary from flat, cylinder, cup, and dish-shaped, allowing for precise control in shaping and polishing materials. Thus, they can be found in various CNC machining processes such as grinding, finishing, deburring, sharpening, and cleaning.

Deburring Wheels

Burrs are tiny irregularities that occur on the surface of a workpiece during the machining process, which can affect the performance of the final product and cause damage to machinery. Thus, the main purpose of deburring wheels is to ensure that the finished product is free from burrs. They come with different features, including abrasive material, size and shape, and hardness, making them suitable for different applications.

Polishing Wheels

Polishing wheels are composed of a variety of materials which include abrasive grains, bonding agents, and fillers. Machinists use them to achieve a polished finish on various types of materials such as metals, plastics, and ceramics. This finish may be required for aesthetic purposes or to improve the functionality of the part.

Abrasive Belts

Abrasive belts are used to shape and finish metal parts, remove burrs and sharp edges, and create smooth surfaces for painting or coating. They are also used to remove old coatings or corrosion from metal surfaces. Abrasive belts can be specified in different grit sizes, allowing operators to refine the surface finish to a desired level of smoothness.

Honing Stones

Honing stones are used for honing or sharpening the edges of various metal tools and components to create smooth and polished surfaces on pipes, cylinders, and other types of metal surfaces. They are typically mounted on a honing tool and moved linearly or rotated against the surface being honed. As the honing tool moves, the abrasive particles on the stone wear away at the surface, removing any roughness, burrs, or other imperfections.

Sanding Discs

Sanding discs are frequently used by machinists for a variety of tasks such as surface finishing, deburring, and material removal. They are typically made of a circular foam or plastic backing covered with abrasive particles bonded with an adhesive or resin and fitted onto a spindle of a CNC machine and used to shape and refine the surface of a workpiece.

Hand Machinist Tools

Another set of essential tools is hand machinist tools, which are integral to any machining shop. Here are some crucial ones:

Allen Wrench Set

An Allen wrench, also called an Allen key or hex key, is a simple tool used for tightening or loosening screws or bolts that have a hexagonal socket. The wrench is L-shaped with one end being a hexagonal shaped tip that fits into the socket of the screw or bolt.

Adjustable Wrench

Also known as 12″ Crescent Wrench, tt’s a versatile hand tool with adjustable jaws that can be opened or closed to fit the size of the nut or bolt, commonly used to tighten or loosen nuts and bolts that are too large for standard wrenches. This means that a single tool can be used for a variety of different sizes.

Ball-peen Hammer

It is a type of hammer that has a rounded or ball-shaped head on one end and a flat face on the other end. The ball-peen hammer is designed for use in metalworking, particularly for shaping and forming metal. They come in a variety of sizes and weights, with heavier hammers being used for more heavy-duty work, and lighter hammers being used for more precise work.

Soft Hammer

The soft hammer is designed to prevent damaging delicate parts or marring surfaces during the manufacturing or repair process. It is made of materials like rubber, plastic, or brass, which are softer than the materials being worked on.

Automatic Center Punch

It is a handheld device used to make an indentation in a workpiece. The punch helps to locate the center of a hole that needs to be drilled in a piece of material. The tool is simple to use, lightweight, and easy to carry around. It is also durable and long-lasting, making it a cost-effective addition to any machine shop.

Basic Machinists Tools

This category features a list of machine tools that are essential in daily machining tasks. These tools are typically required for the majority of projects.

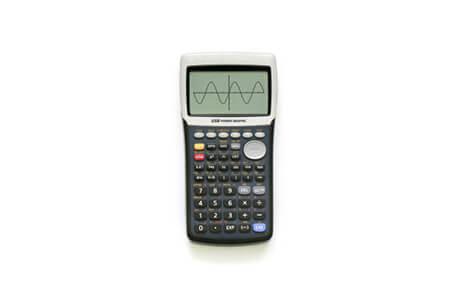

Scientific Calculator

Having a scientific calculator with special functions such as sine, cosine, and tangent is essential for a skilled machinist. Unlike a grocery calculator, it is necessary for quick and accurate trigonometry calculations. When selecting a calculator, consider your needs and whether a pocket-sized or PC-installed version is appropriate. Avoid relying on a smartphone for this type of work, and instead, use a laptop for easy access and efficient completion of tasks.

6” Scale Ruler

The process of measuring the components of a workpiece is crucial in any machining task. This is where the 6″ scale ruler comes in handy as it can accurately measure the length and maintain a constant ratio of the measurement. The 6″ scale ruler can be utilized in various manufacturing processes to measure different parts. It’s essential to select the appropriate type with the necessary features required for the job.

Conclusion

Understanding the appropriate tools for machining is critical for productivity and efficiency in a workshop, whether you own or work in one. This article recommends essential machinist tools for machining operations in four main categories.

The Best CNC Machine Shop for Your Machining Projects – Runsom

We hope that this article has helped you in some way with regard to the list of machine shop tools. If you’re looking for high-quality machining services, consider outsourcing to Runsom. We’re a CNC machine shop with extensive experience in the CNC machining field and easily meet your requests. Get an instant quote today!

Other Articles You May be Interested in: