The agricultural sector is increasingly embracing Computer Numerical Control (CNC) machining techniques, marking a significant advancement in production and maintenance processes for agricultural machinery. The widespread adoption of CNC machining is attributed to its capacity to enhance precision, efficiency, and error reduction compared to manual operations.

This discourse aims to delve into the multifaceted benefits, versatile applications, and illustrative examples of CNC machining in the agricultural domain. Additionally, it will explore advanced processing methodologies, strategic insights into agricultural machinery part production, material considerations, various numerical control processes, and actionable recommendations for practitioners in the field.

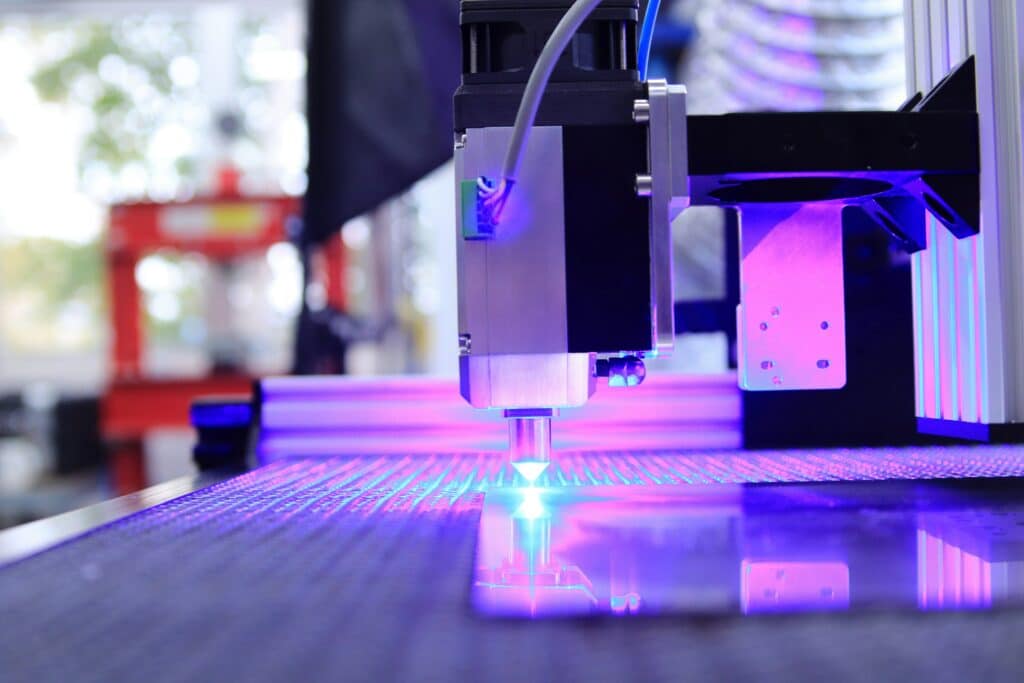

Introduction to CNC machining technology

Definition and Principle

CNC machining (Computer Numerical Control, CNC) is a technology that uses computer control to precisely process workpieces by controlling machine tools and equipment. It involves pre-programmed computer instructions for precise cutting, forming, and processing of workpieces through a three-dimensional coordinate system.

History and Development

CNC machining technology traces its roots back to the 1940s, with significant development starting in the 1950s and 1960s. Early systems were controlled by microprocessors, but modern CNC systems use more powerful computer systems for greater accuracy and efficiency. Over the decades, CNC machining technology has evolved from single-function systems to modern equipment with multi-axis control and advanced surface processing capabilities. Advancements in computer and automation control technologies have propelled CNC machining to play a crucial role in the manufacturing industry’s automation and intelligent development.

Advantages of CNC Machining in Agriculture

CNC machining offers several benefits in the agricultural industry. By leveraging this technology, farmers can optimize their operations, increase productivity, and reduce downtime and costs. Here are some of the key advantages:

| Precision | CNC machines can produce parts with high accuracy and repeatability, which is essential for maintaining the performance of agricultural equipment. This precision ensures that components fit together correctly and operate smoothly, reducing the risk of breakdowns and increasing the lifespan of equipment. |

| Efficiency | CNC machining allows for the production of complex parts in a single setup, reducing the need for multiple setups and manual adjustments. This not only saves time but also reduces labor costs and waste. Additionally, CNC machines can run unattended for long periods, allowing for continuous production and increased efficiency. |

| Versatility | CNC machines can work with a variety of materials, including metals, plastics, and composites. This versatility allows farmers to produce a wide range of parts and components for different types of equipment, from tractors and harvesters to irrigation systems and storage tanks. |

| Customization | CNC machining enables the production of custom parts and components to meet specific requirements. Farmers can have parts made to fit their existing equipment or design new components to improve performance and efficiency. This level of customization can help farmers optimize their operations and increase productivity. |

| Quality | CNC machining produces high-quality parts that are consistent and free from defects. This ensures that agricultural equipment operates at peak performance and reduces the need for repairs and maintenance. High-quality parts also contribute to longer equipment life and lower overall operating costs. |

Applications and Instances of CNC Machining in Agricultural Components

CNC machining is a versatile technology that plays a significant role in the agricultural sector. It involves the use of computer-controlled machines to shape and process various materials such as metals, plastics, and composites into precise components for agricultural equipment. Here are some applications and examples of CNC-machined agricultural components:

Tractor Components

CNC machining can produce parts such as gears, sprockets, axles, and hydraulic fittings for tractors. These components must be highly durable and precisely manufactured to ensure the tractor’s performance and safety.

Plow Parts

Plows require intricate components like moldboards, shanks, and coulters that can be efficiently produced using CNC machining. The precision of these parts is crucial for maintaining the correct angle and depth during tillage operations.

Harvester Parts

CNC machining is used to create complex components for harvesters, including cutter bars, reels, and bearing housings. These components must endure harsh conditions and perform consistently to maximize crop yield.

Greenhouse Structures

Precision-machined aluminum or steel frames and connectors can be used to construct greenhouses. CNC technology ensures the strength and durability required for these structures to withstand environmental stresses.

Feeders and Mixers

CNC machining can produce parts for feeders and mixers, such as augers, screw conveyors, and mixing blades. These components must be strong enough to handle the abrasive nature of feed while maintaining accuracy in the delivery of consistent rations to livestock.

Precision CNC Machining Techniques for Agricultural Machinery Parts

Precision CNC machining technology for agricultural machinery parts is an essential manufacturing process. Here are several key steps in the process:

· Designing parts:

Initially, corresponding part drawings must be designed based on the needs and requirements of agricultural machinery. This involves the expertise of mechanical engineers, considering factors such as shape, size, and material.

· Programming:

Next, the processing paths and procedures need to be translated into instruction codes understandable by CNC machine tools. Computer-aided design (CAD) and computer-aided manufacturing (CAM) software are used to efficiently write programs.

· Material preparation:

Appropriate materials are selected according to part requirements, undergoing pre-processing such as cutting and heat treatment. This enhances material properties and ensures final part quality.

· Precision machining:

The pre-processed material is clamped onto the CNC machine tool for precision machining. Following the programmed instructions, the machine tool automatically performs cutting, drilling, milling, etc., achieving high precision and efficiency while minimizing errors.

· Inspection and adjustment:

After processing, parts are inspected to ensure quality meets requirements. Any issues identified are adjusted and corrected based on inspection results, with further processing as needed until requirements are met.

· Surface treatment:

Some parts require surface treatment such as heat treatment, sandblasting, or electroplating to improve wear resistance, corrosion resistance, and aesthetics.

Through these steps, precision CNC machining technology for agricultural machinery parts achieves high precision and efficiency, enhancing machinery quality and performance while reducing errors and improving production efficiency.

Efficient CNC Machining Strategies for Agricultural Machinery Parts

Efficient CNC machining strategies for agricultural machinery parts aim to improve processing efficiency and quality. This strategy involves steps such as demand analysis, equipment selection, procedure writing, tool and fixture preparation, processing operations, quality inspection, and equipment maintenance.

Overall, CNC machining in agriculture continues to advance, offering more precise and efficient solutions for agricultural production.

Commonly Used Materials for CNC Machining in the Agricultural Industry

Aluminum

Aluminum is light, easy to machine, and has good corrosion resistance. It is suitable for manufacturing various agricultural parts, such as brackets, casings, etc.

Stainless Steel

Stainless steel is hard, durable, and rust-resistant. It is often used to make rakes, plows, and other heavy farm equipment, especially those involved in food processing and storage.

Plastic

Plastic offers versatility, corrosion resistance, and low cost which is used to make precision parts such as gears, bearings, and other components that need to withstand wear and tear.

Polycarbonate

Polycarbonate is a strong, lightweight plastic that resists impact and UV radiation, making it suitable for greenhouse structures and protective gear.

Titanium

Although titanium is more expensive, it is very strong, lightweight, and corrosion-resistant, making it suitable for certain agricultural machinery and equipment.

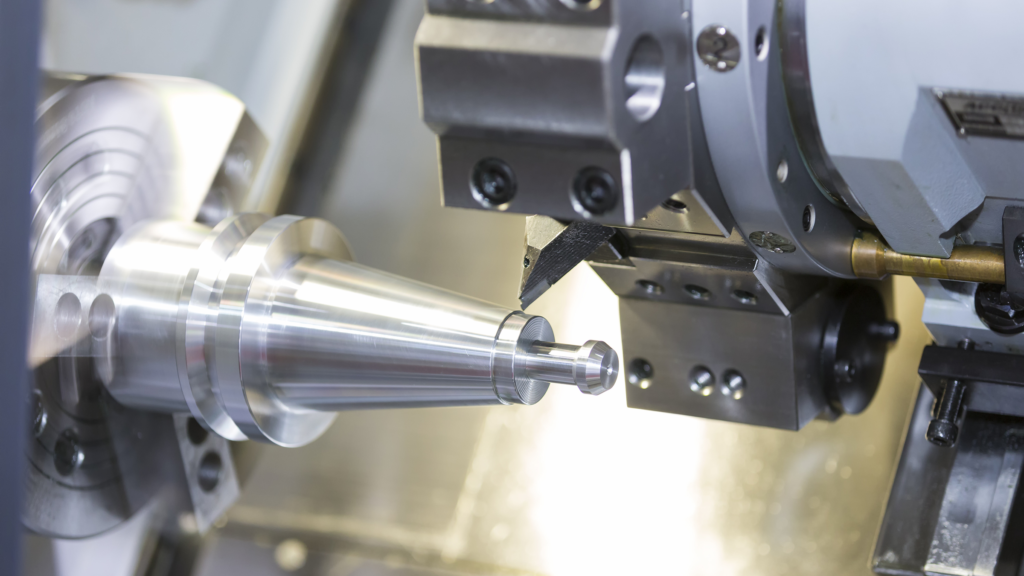

Various Machining Techniques for Producing Agricultural Components

Agricultural parts can be manufactured using a variety of machining processes, each with its unique advantages and applications. Here are some of the most common machining processes used in the manufacturing of agricultural parts:

This process involves the use of rotating cutters to remove material from a workpiece. Milling machines can produce complex shapes and features on agricultural parts, such as grooves, slots, and contours.

In this process, the workpiece rotates while a cutting tool removes material. Turning is commonly used to manufacture cylindrical parts like shafts and spindles for agricultural equipment.

This process uses a drill bit to create holes in a workpiece. Drilling is common for creating mounting holes, coolant passages, or other types of holes in agricultural parts.

Boring

Boring enlarges existing holes in a workpiece, creating precise holes with a smooth finish, often required for bearings or critical components in agricultural equipment.

Sheet metal forming

This process shapes sheet metal into desired shapes and sizes using punches, dies, and other tools. It’s common for manufacturing panels, brackets, and other sheet metal components for agricultural equipment.

How to Select the Ideal CNC Firm for Your Agricultural Machining Venture?

Choosing the right CNC company for your machined agricultural project is an important decision that directly impacts your ability to obtain high-quality results that meet your specific needs. The following tips will help you select the most suitable CNC company:

| Experience | Check whether the CNC company you choose has extensive experience in the agricultural industry, a track record of completing similar projects, and highly specialized knowledge and capabilities. |

| Quality | Check that the CNC company you choose is focused on quality, ask for samples of past work, and check for any defects. |

| Technology | Ensure that the CNC company you choose is quality-focused. Ask for samples of their past work and check for any defects. |

| Customization | Check whether the CNC company you choose offers customization services to meet your unique requirements. |

| Customer Service | Check that the CNC company you choose is easy to communicate with, responds to your questions and concerns promptly, and provides updates on project progress. |

FAQs

Conclusion

Computer Numerical Control (CNC) ) machining plays a crucial role in the field of agricultural machinery manufacturing. It utilizes computer programs to precisely control the motion and operation of mechanical equipment, enabling the high-precision and high-efficiency production of complex parts. However, despite the numerous benefits brought by CNC technology, it also faces challenges. These include the high cost of equipment investment, the need for skilled technical personnel, and the requirement for complex programming skills. Nevertheless, with the continuous advancement of technology and the gradual reduction of costs, the prospects for the application of CNC machining in the agricultural machinery manufacturing industry will become even broader. Over time, we can expect to see this technology playing a greater role in the agricultural sector, contributing more to improving production efficiency, optimizing product quality, and reducing production costs.

Obtaining Customized Agricultural Parts at Runson Precision

Now choose Runson Precision, and you’ll receive excellent and reliable machining services, providing robust support for the production of your agricultural equipment, ensuring its reliability and performance. Our services cover comprehensive CNC machining, specifically designed to meet the unique requirements of agricultural machinery parts. We base our operations on stringent quality control to ensure that every machined part meets our customers’ strict standards. Additionally, our team of engineers will provide you with professional advice and customized machining solutions to ensure you obtain economically efficient and superior-quality final products.

Other Articles You May Be Interested in: