The AISI/SAE steel grading system ingeniously employs a four-digit code to distinguish steel types based on chemical composition. Follow our comprehensive guide and master the language of steel, ensuring you select the ideal material for every project with confidence and expertise.

The AISI/SAE Steel Grades System Explained

In the 1930s and 1940s, the American Iron and Steel Institute (AISI) and the Society of Automotive Engineers (SAE) jointly standardized a system for classifying steels and other iron-based alloys. This effort culminated in the AISI/SAE steel grades, a unified system that has been used for decades.

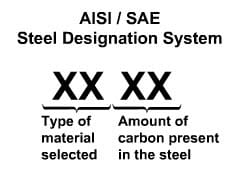

This system employs a four-digit numeric code to differentiate alloy and carbon steels based on their chemical makeup. The first two digits signify the primary alloying elements, while the last two reflect the carbon content.

A diagram further illustrates the composition of the AISI/SAE steel designation system.

In the industry, references to both SAE and AISI are common, often used interchangeably without precise distinction. For instance, steel might be referred to as “4140”, “AISI 4140”, or “SAE 4140”, and in many non-critical applications, these designations are considered equivalent.

However, for general purposes, the numerical code is more commonly used. In specific designs or drawings, the steel is identified with a precise standard, such as “4140 bar per ASTM-A108″ or “4140 bar per AMS 6349″.

It is worth noting that the AISI does not write standards in themselves, but only specifies the range of chemical compositions of the different grades of steel, and usually needs to be used in conjunction with a standard. (e.g. ASTM, ASME, or SAE, etc.)

The Four-Digit Index Classification of Steels

The AISI/SAE system uses a 4-digit number to identify the chemical composition of alloy and carbon steels. The first digit indicates the main alloying elements, the second digit the top grade elements, and the last two digits show the carbon content in hundredths of a percent. For example, AISI/SAE 1020 steel is a plain-carbon steel containing 0.20 wt% C.

First Digit

The first digit in AISI/SAE steel designation represents a broad category of steel. For instance, the 1xxx series within the SAE-AISI system denotes carbon steels, subdivided into four classes based on their properties. The 10xx series includes plain carbon steels with up to 1.00% Mn, the 11xx series includes resulfurized carbon steels, the 12xx series includes resulfurized and rephosphorized carbon steels, and the 15xx series represents non-resulfurized high-manganese carbon steels.

The first digit reflects the major class of steel provided as follows:

| SAE Designation | Type |

| 1xxx | Carbon steels |

| 2xxx | Nickel steels |

| 3xxx | Nickel-chromium steels |

| 4xxx | Molybdenum steels |

| 5xxx | Chromium steels |

| 6xxx | Chromium-vanadium steels |

| 7xxx | Tungsten steels |

| 8xxx | Nickel-chromium-molybdenum steels |

| 9xxx | Silicon-manganese steels |

Second Digit

The second digit indicates major elements affecting the steel’s properties. In 1018 steel, for example, the zero suggests the absence of significant secondary elements like sulfur.

Third and Fourth Digits

The last two digits usually indicate the carbon content in the alloy, representing the average carbon content in hundredths of a percent, such as 0.18% in AISI/SAE 1018 or roughly 0.4% in AISI/SAE 4340.

Prefix and Suffix

Additionally, the AISI system uses letter prefixes to denote the steelmaking process, like “C” for open-hearth, electric arc, or basic oxygen furnace steel, and “E” for electric arc furnace steel. The prefix “M” is used for merchant quality steels used in non-critical machinery parts.

Sometimes, an extra letter is added between the second and third digits (e.g., 11L41, 12L14, or 50B40), where “L” indicates added lead for machinability, and “B” signifies boron to enhance steel hardness.

Suffixes may also be added to specify the forming process, like cold working (CDS), hot working (HR), or quenching and tempering (Q&T). An “H” suffix indicates a focus on hardenability, with specific hardness requirements outlined in a Jominy test.

Carbon and Alloy Steel Grades – The AISI/SAE Steel Designation System

| Type of Steel | AISI/SAE Designation | Composition by weight |

|---|---|---|

| Carbon Steel | 10xx | Plain carbon (Mn 1.00% max) |

| 11xx | Resulfurized | |

| 12xx | Resulfurized and rephosphorized | |

| 15xx | Plain carbon (Mn 1.00-1.65%) | |

| Manganese Steel | 13xx | Mn 1.75% |

| Nickel Steel | 20xx | Ni 0.50% |

| 21xx | Ni 1.50% | |

| 23xx | Ni 3.50% | |

| 25xx | Ni 5.00% | |

| Nickel-Chromium Steel | 31xx | Ni 1.25%, Cr 0.65% or 0.80% |

| 32xx | Ni 1.25%, Cr 1.07% | |

| 33xx | Ni 3.50%, Cr 1.50% or 1.57% | |

| 34xx | Ni 3.00%, Cr 0.77% | |

| Molybdenum Steel | 40xx | Mo 0.20%, 0.25%, or Mo 0.25% and S 0.042% |

| 44xx | Mo 0.40% or 0.52% | |

| Chromium-Molybdenum Steel | 41xx | Cr 0.50%, 0.80%, or 0.95%; Mo 0.12%, 0.20%, 0.25%, or 0.30% |

| Nickel-Chromium-Molybdenum Steel | 43xx | Ni 1.82%, Cr 0.50% to 0.80%, Mo 0.25% |

| 43BVxx | Ni 1.82%, Cr 0.50%, Mo 0.12% or 0.35%, V 0.03% min | |

| 47xx | Ni 1.05%, Cr 0.45%, Mo 0.20% or 0.35% | |

| 81xx | Ni 0.30%, Cr 0.40%, Mo 0.12% | |

| 81Bxx | Ni 0.30%, Cr 0.45%, Mo 0.12% | |

| 86xx | Ni 0.55%, Cr 0.50%, Mo 0.20% | |

| 87xx | Ni 0.55%, Cr 0.50%, Mo 0.25% | |

| 88xx | Ni 0.55%, Cr 0.50%, Mo 0.35% | |

| 93xx | Ni 3.25%, Cr 1.20%, Mo 0.12% | |

| 94xx | Ni 0.45%, Cr 0.40%, Mo 0.12% | |

| 97xx | Ni 0.55%, Cr 0.20%, Mo 0.20% | |

| 98xx | Ni 1.00%, Cr 0.80%, Mo 0.25% | |

| Nickel-Molybdenum Steel | 46xx | Ni 0.85% or 1.82%, Mo 0.20% or 0.25% |

| 48xx | Ni 3.50%, Mo 0.25% | |

| Chromium Steel | 50xx | Cr 0.27% or 0.40% or 0.50% or 0.65% |

| 50xxx | Cr 0.50%, C 1.00% min | |

| 50Bxx | Cr 0.28% or 0.50% | |

| 51xx | Cr 0.80% or 0.87% or 0.92% or 1.00% or 1.05% | |

| 51xxx | Cr 1.02%, C 1.00% min | |

| 51Bxx | Cr 0.80%; and added boron | |

| 52xxx | Cr 1.45%, C 1.00% min | |

| Chromium-Vanadium Steel | 61xx | Cr 0.60%, 0.80%, 0.95%; V 0.10%, or 0.15% min |

| Tungsten-Chromium Steel | 72xx | W 1.75%, Cr 0.75% |

| Silicon-Manganese Steel | 92xx | Si 1.40%, or 2.00%; Mn 0.65%, 0.82%, or 0.85%; Cr 0.00%, or 0.65% |

| High-strength Low-alloy Steel | 9xx | Various SAE grades |

| xxBxx | “B” denotes Boron Steels | |

| xxLxx | “L” denotes Leaded Steels |

Stainless steels are also included in the AISI steel specifications range, identified by three-digit numbers, each with unique characteristics. Here are the key aspects of this system:

- 200 Series: Austenitic stainless steels containing chromium, nickel, and manganese. They are known for good corrosion resistance and formability. Examples include AISI 201 and 202.

- 300 Series: Also austenitic, these steels contain chromium and nickel, offering excellent corrosion resistance and mechanical properties. Common types are AISI 304 (18% chromium, 8% nickel) and AISI 316, which adds molybdenum for even better corrosion resistance.

- 400 Series: These are ferritic and martensitic stainless steels, primarily containing chromium. They have magnetic properties and are generally less corrosion-resistant than the 300 series. Examples are AISI 410 (martensitic) and AISI 430 (ferritic).

- 500 Series: Heat-resisting chromium alloys, not commonly used in standard applications.

- 600 Series: Originally developed for proprietary alloys (not standardized by AISI anymore), these are martensitic precipitation hardening stainless steels.

- Precipitation Hardening (PH) Grades: These are chromium-nickel stainless steels that contain alloying elements such as copper, aluminum, or titanium, which allow them to be hardened by a solution and aging heat treatment. They are designated as 17-4PH, 15-5PH, etc.

- Duplex Series: Not part of the original AISI system, but important in modern stainless steel classifications. Duplex stainless steels have a mixed microstructure of austenite and ferrite, offering a balance of strength and corrosion resistance.

The letter in this designation system denotes:

- “L”: Indicates a lower carbon content, which enhances the steel’s weldability and reduces its susceptibility to corrosion. For example, 316L has a lower carbon content than 316.

- “H”: Designates high carbon content, improving the steel’s strength at high temperatures. For example, 304H.

- “F”: Indicates the steel is free machining, meaning it has been designed to produce small chips when machined, making it easier to work with.

- “PH”: Stands for Precipitation Hardening, indicating a steel that can be hardened by a special heat treatment process. Grades like 17-4PH fall into this category.

It’s important to note that the AISI itself does not write standards; it only classifies and describes different grades of steel. The actual standards for stainless steel are often established by organizations such as the American Society for Testing and Materials (ASTM) or the American National Standards Institute (ANSI). Therefore, while AISI provides the classification system for various grades of steel, including stainless steel, the detailed standards and specifications for these materials are typically published under ASTM or ANSI designations.

| Type | Designation | Composition by weight (%) | |||||||||

| SAE | UNS | Cr | Ni | C | Mn | Si | P | S | N | Other | |

| Austenitic | 201 | S20100 | 16–18 | 3.5–5.5 | 0.15 | 5.5–7.5 | 0.75 | 0.06 | 0.03 | 0.25 | - |

| 202 | S20200 | 17–19 | 4–6 | 0.15 | 7.5–10.0 | 0.75 | 0.06 | 0.03 | 0.25 | - | |

| 205 | S20500 | 16.5–18 | 1–1.75 | 0.12–0.25 | 14–15.5 | 0.75 | 0.06 | 0.03 | 0.32–0.40 | - | |

| 254 | S31254 | 20 | 18 | 0.02 max. | - | - | - | - | 0.20 | 6 Mo; 0.75 Cu; "Super austenitic"; All values nominal | |

| 301 | S30100 | 16–18 | 6–8 | 0.15 | 2 | 0.75 | 0.045 | 0.03 | - | - | |

| 302 | S30200 | 17–19 | 8–10 | 0.15 | 2 | 0.75 | 0.045 | 0.03 | 0.1 | - | |

| 302B | S30215 | 17–19 | 8–10 | 0.15 | 2 | 2.0–3.0 | 0.045 | 0.03 | - | - | |

| 303 | S30300 | 17–19 | 8–10 | 0.15 | 2 | 1 | 0.2 | 0.15 min. | - | Mo 0.60 (optional) | |

| 303Se | S30323 | 17–19 | 8–10 | 0.15 | 2 | 1 | 0.2 | 0.06 | - | 0.15 Se min. | |

| 304 | S30400 | 18–20 | 8–10.50 | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 0.1 | - | |

| 304L | S30403 | 18–20 | 8–12 | 0.03 | 2 | 0.75 | 0.045 | 0.03 | 0.1 | - | |

| 304Cu | S30430 | 17–19 | 8–10 | 0.08 | 2 | 0.75 | 0.045 | 0.03 | - | 3–4 Cu | |

| 304N | S30451 | 18–20 | 8–10.50 | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 0.10–0.16 | - | |

| 305 | S30500 | 17–19 | 10.50–13 | 0.12 | 2 | 0.75 | 0.045 | 0.03 | - | - | |

| 308 | S30800 | 19–21 | 10–12 | 0.08 | 2 | 1 | 0.045 | 0.03 | - | - | |

| 309 | S30900 | 22–24 | 12–15 | 0.2 | 2 | 1 | 0.045 | 0.03 | - | - | |

| 309S | S30908 | 22–24 | 12–15 | 0.08 | 2 | 1 | 0.045 | 0.03 | - | - | |

| 310 | S31000 | 24–26 | 19–22 | 0.25 | 2 | 1.5 | 0.045 | 0.03 | - | - | |

| 310S | S31008 | 24–26 | 19–22 | 0.08 | 2 | 1.5 | 0.045 | 0.03 | - | - | |

| 314 | S31400 | 23–26 | 19–22 | 0.25 | 2 | 1.5–3.0 | 0.045 | 0.03 | - | - | |

| 316 | S31600 | 16–18 | 10–14 | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 0.10 | 2.0–3.0 Mo | |

| 316L | S31603 | 16–18 | 10–14 | 0.03 | 2 | 0.75 | 0.045 | 0.03 | 0.10 | 2.0–3.0 Mo | |

| 316F | S31620 | 16–18 | 10–14 | 0.08 | 2 | 1 | 0.2 | 0.10 min. | - | 1.75–2.50 Mo | |

| 316N | S31651 | 16–18 | 10–14 | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 0.10–0.16 | 2.0–3.0 Mo | |

| 317 | S31700 | 18–20 | 11–15 | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 0.10 max. | 3.0–4.0 Mo | |

| 317L | S31703 | 18–20 | 11–15 | 0.03 | 2 | 0.75 | 0.045 | 0.03 | 0.10 max. | 3.0–4.0 Mo | |

| 321 | S32100 | 17–19 | 9–12 | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 0.10 max. | Ti 5(C+N) min., 0.70 max. | |

| 329 | S32900 | 23–28 | 2.5–5 | 0.08 | 2 | 0.75 | 0.04 | 0.03 | - | 1–2 Mo | |

| 330 | N08330 | 17–20 | 34–37 | 0.08 | 2 | 0.75–1.50 | 0.04 | 0.03 | - | - | |

| 347 | S34700 | 17–19 | 9–13 | 0.08 | 2 | 0.75 | 0.045 | 0.030 | - | Nb + Ta, 10 × C min., 1 max. | |

| 348 | S34800 | 17–19 | 9–13 | 0.08 | 2 | 0.75 | 0.045 | 0.030 | - | Nb + Ta, 10 × C min., 1 max., but 0.10 Ta max.; 0.20 Ca | |

| 384 | S38400 | 15–17 | 17–19 | 0.08 | 2 | 1 | 0.045 | 0.03 | - | - | |

| Ferritic | 405 | S40500 | 11.5–14.5 | - | 0.08 | 1 | 1 | 0.04 | 0.03 | - | 0.1–0.3 Al, 0.60 max. |

| 409 | S40900 | 10.5–11.75 | 0.05 | 0.08 | 1 | 1 | 0.045 | 0.03 | - | Ti 6 × (C + N) [14] | |

| 429 | S42900 | 14–16 | 0.75 | 0.12 | 1 | 1 | 0.04 | 0.03 | - | - | |

| 430 | S43000 | 16–18 | 0.75 | 0.12 | 1 | 1 | 0.04 | 0.03 | - | - | |

| 430F | S43020 | 16–18 | - | 0.12 | 1.25 | 1 | 0.06 | 0.15 min. | - | 0.60 Mo (optional) | |

| 430FSe | S43023 | 16–18 | - | 0.12 | 1.25 | 1 | 0.06 | 0.06 | - | 0.15 Se min. | |

| 434 | S43400 | 16–18 | - | 0.12 | 1 | 1 | 0.04 | 0.03 | - | 0.75–1.25 Mo | |

| 436 | S43600 | 16–18 | - | 0.12 | 1 | 1 | 0.04 | 0.03 | - | 0.75–1.25 Mo; Nb+Ta 5 × C min., 0.70 max. | |

| 442 | S44200 | 18–23 | - | 0.2 | 1 | 1 | 0.04 | 0.03 | - | - | |

| 446 | S44600 | 23–27 | 0.25 | 0.2 | 1.5 | 1 | 0.04 | 0.03 | - | - | |

| Martensitic | 403 | S40300 | 11.5–13.0 | 0.60 | 0.15 | 1 | 0.5 | 0.04 | 0.03 | - | - |

| 410 | S41000 | 11.5–13.5 | 0.75 | 0.15 | 1 | 1 | 0.04 | 0.03 | - | - | |

| 414 | S41400 | 11.5–13.5 | 1.25–2.50 | 0.15 | 1 | 1 | 0.04 | 0.03 | - | - | |

| 416 | S41600 | 12–14 | - | 0.15 | 1.25 | 1 | 0.06 | 0.15 min. | - | 0.060 Mo (optional) | |

| 416Se | S41623 | 12–14 | - | 0.15 | 1.25 | 1 | 0.06 | 0.06 | - | 0.15 Se min. | |

| 420 | S42000 | 12–14 | - | 0.15 min. | 1 | 1 | 0.04 | 0.03 | - | - | |

| 420F | S42020 | 12–14 | - | 0.15 min. | 1.25 | 1 | 0.06 | 0.15 min. | - | 0.60 Mo max. (optional) | |

| 422 | S42200 | 11.0–12.5 | 0.50–1.0 | 0.20–0.25 | 0.5–1.0 | 0.5 | 0.025 | 0.025 | - | 0.90–1.25 Mo; 0.20–0.30 V; 0.90–1.25 W | |

| 431 | S41623 | 15–17 | 1.25–2.50 | 0.2 | 1 | 1 | 0.04 | 0.03 | - | - | |

| 440A | S44002 | 16–18 | - | 0.60–0.75 | 1 | 1 | 0.04 | 0.03 | - | 0.75 Mo | |

| 440B | S44003 | 16–18 | - | 0.75–0.95 | 1 | 1 | 0.04 | 0.03 | - | 0.75 Mo | |

| 440C | S44004 | 16–18 | - | 0.95–1.20 | 1 | 1 | 0.04 | 0.03 | - | 0.75 Mo | |

| Heat resisting | 501 | S50100 | 4–6 | - | 0.10 min. | 1 | 1 | 0.04 | 0.03 | - | 0.40–0.65 Mo |

| 502 | S50200 | 4–6 | - | 0.1 | 1 | 1 | 0.04 | 0.03 | - | 0.40–0.65 Mo | |

| Martensitic precipitation hardening | 630 | S17400 | 15–17 | 3–5 | 0.07 | 1 | 1 | 0.04 | 0.03 | - | Cu 3–5, Ta 0.15–0.45 |

Conclusion

Knowing the composition helps in predicting the material’s properties like strength, ductility, weldability, and suitability for certain manufacturing processes. The SAE steel grades system, by providing a clear and concise way to categorize and understand the primary alloying elements and carbon content of the steel, makes it easier for manufacturers, engineers, and designers to select the right type of steel for their specific needs, whether for construction, automotive applications, tools, or machinery.

Steel CNC Machining Solutions Provider – Runsom Precision

Are you looking for a reliable manufacturer to fabricate your steel parts or are you confused about how to choose the right type of steel for the specific project? You can find answers to these problems at Runsom Precision. We have extensive experience in steel CNC machining for more than a decade and our experts are well-equipped with knowledge in various standards, properties, and chemical composition of the steel as well as other materials. Get an instant quote online to get started with your project today!

Other Articles You May Be Interested in: