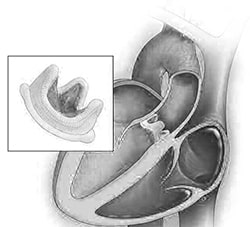

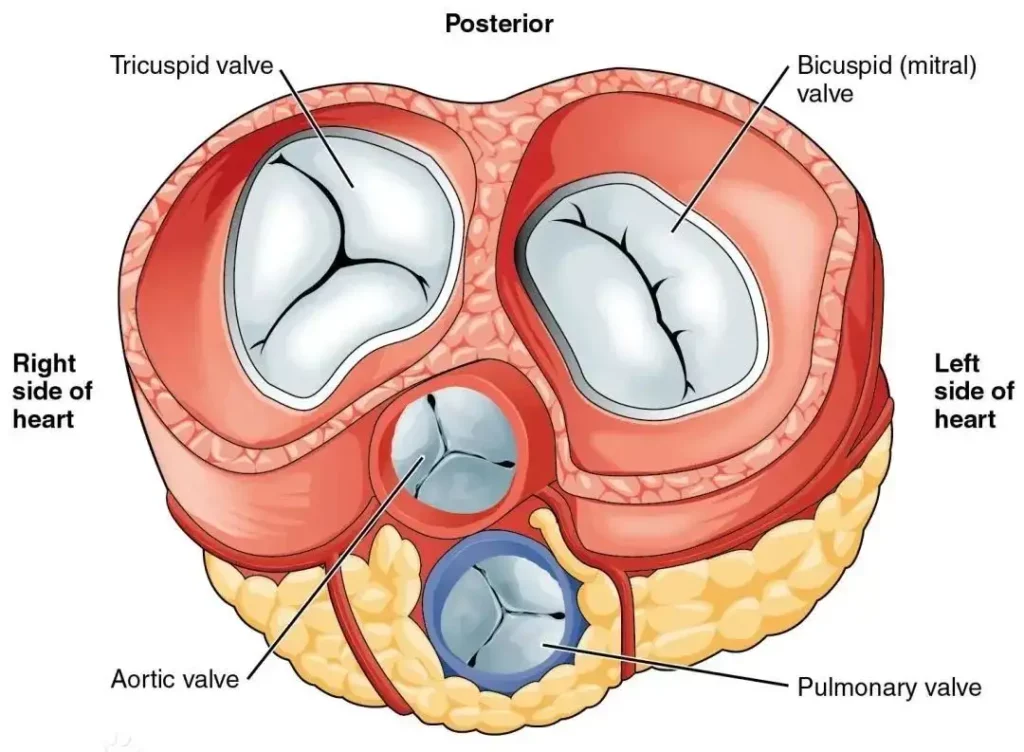

The heart valve is an important medical device used to help maintain the normal flow of blood within the heart. There are various types of heart valves, including the aortic valve, pulmonary valve, mitral valve, and tricuspid valve, each with specific functions and forms to meet different physiological needs and pathological conditions. When natural heart valves are damaged or functionally limited, prosthetic ones can be used as replacements.

A prosthetic heart valve is mainly divided into two types:

| Mechanical valve | Composed of metal or alloy materials, these valves are durable and stable, effectively assisting the heart with normal blood flow for extended periods. The advantages of mechanical valves include durability and resistance to degeneration, but patients need to take anticoagulant drugs for life to prevent blood clots. |

| Biological valves | They are typically made from animal tissues or artificial biomaterials, similar to the patient’s natural valve tissues. Biological valves have the advantage of good biocompatibility and do not require lifelong use of anticoagulant drugs, but they may not be as durable as mechanical valves. |

The advanced processing technology and equipment at Runsom Precision, including CNC machine tools and 3D printing technology, ensure the production of high-precision custom heart valves. Additionally, the company is equipped with high-precision testing equipment, such as CMM (Coordinate Measuring Machine) and X-ray inspection equipment, to comprehensively inspect product quality. Please feel free to contact us at any time to obtain an instant quote.

Other Articles You May Be Interested in: