In today’s rapidly evolving industrial landscape, the need for custom shaft manufacturing has become increasingly evident. From the intricacies of CNC techniques to the wide array of materials available for machining shaft parts, the exploration of this crucial subject holds immense significance for various industries.

This article aims to delve into the concept and significance of custom shaft manufacturing, shedding light on its development prospects, advantages, machining techniques, surface finishing options, types, applications, and crucial considerations.

Concept and Significance of Custom Shaft Manufacturing

Custom shaft manufacturing involves designing and manufacturing shaft components that meet specific performance requirements based on customer needs for particular applications. In contrast to traditional standardized production, custom shaft manufacturing emphasizes personalization and differentiation to better address customers’ special needs.

Custom shafts play a pivotal role in various mechanical systems, serving as the linchpin that enables the smooth and efficient transmission of power, motion, or torque. Unlike standard off-the-shelf shafts, custom shafts are meticulously designed and manufactured to meet exacting specifications, ensuring seamless integration within diverse applications. The nuances of custom shaft manufacturing allow for tailored solutions that cater to the unique demands of each industrial sector, enhancing overall performance and reliability.

Applications of Custom Shaft

Given their high level of customization and specialization, custom shafts have found extensive applications across multiple fields:

Custom shafts enhance vehicle performance, reliability, and driving experience in critical components such as engines, transmission systems, and suspension systems.

Aerospace Industry

Key components like aircraft engines, turbines, and aerospace electrical systems heavily rely on custom shafts for high performance and reliability, crucial for industry safety and efficiency.

Heavy Machinery Industry

Essential equipment including mining machinery, metallurgical equipment, and construction machinery benefit from the high load capacity and durability of custom shafts, ensuring smooth operation and efficient production.

Custom shafts, from machine tool spindles to shredder shafts, elevate equipment performance and efficiency.

Other Fields

Beyond the mentioned sectors, industries such as petroleum natural gas, and medical devices, can customize shaft products to suit specific application requirements.

The Development Prospects for Custom Shaft

| Technological Advancement | Advancements in mechanical design, electronics, and control technology will enhance precision and efficiency, enabling custom shafts to meet complex application requirements. |

| Market Demand Growth | Increasing customization trend in industries drives consumer preference for personalized products, boosting demand for custom shafts. |

| Expansion of Industry Applications | Custom shafts are extensively used in electronics, automotive, home furnishings, and healthcare, with demand expected to expand as these industries evolve. |

| Improved Production Efficiency | Automation and intelligent production lines can significantly boost production efficiency, reducing costs and enhancing market competitiveness for custom shafts. |

Advantages of Custom Shaft Manufacturing and CNC Technology

| Personalized Customization | Meeting special requirements in different application scenarios, enhancing the performance and reliability of mechanical equipment. |

| High-Precision Manufacturing | Ensuring stability and consistency of product quality, enhancing the overall performance and service life of mechanical equipment. |

| High-Efficiency Production | Completing a large number of complex part machining tasks in a short time, improving production efficiency, and reducing production costs. |

| Flexibility and Adaptability | Quickly responding to market changes and the diversity of customer demands, meeting personalized customer needs. |

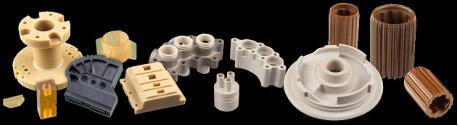

Materials for Machining Shaft Parts

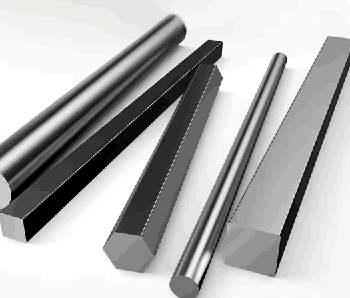

A variety of materials can be used to machine shaft parts, each catering to distinct design requirements and practical applications. Here are the commonly used materials for shaft part machining:

Carbon Steel

Renowned for its robust strength and hardness, it is well-suited for shaft parts with general performance requirements.

Stainless Steel

Ideal for shaft parts used in marine environments or applications requiring corrosion resistance.

Alloy Steel

Offers heightened strength and hardness, an optimal choice for high-stress shaft parts demanding wear resistance

Aluminum Alloy

Its lightweight nature and excellent thermal conductivity make it ideal for shaft parts where weight reduction is crucial without compromising performance.

Titanium Alloy

Notable for exceptional strength and corrosion resistance, making it suitable for shaft parts subjected to demanding requirements in terms of strength and corrosion resistance.

Copper

Boasting exceptional thermal and electrical conductivity, it is well-matched for shaft parts requiring superior performance in these areas.

Plastic

A viable option for shaft parts where strength requirements are not paramount, due to its cost-effectiveness and commendable wear resistance.

Fabricating Custom Machined Shaft

Here are the general steps for machining a custom machined shaft:

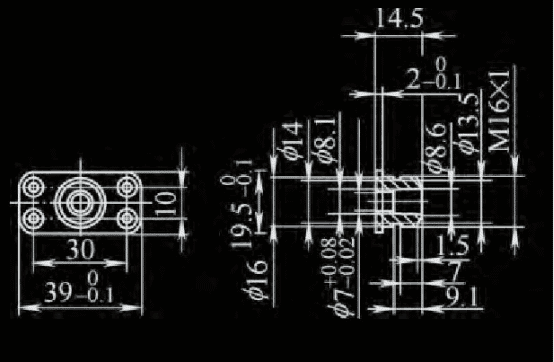

Determine design requirements

Initially, clarify the diameter, length, axial and radial tolerances, and other design requirements of the shaft.

Choose the appropriate material

Select a suitable material, such as carbon steel, stainless steel, or alloy steel, based on the shaft’s utilization requirements and environmental conditions.

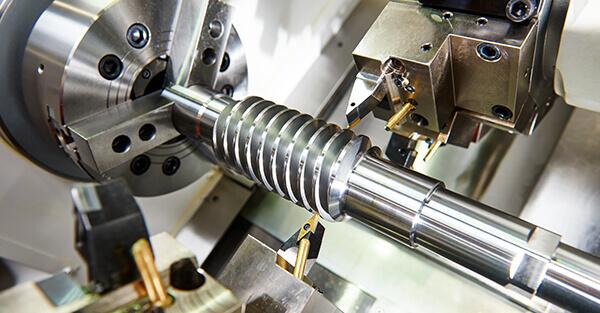

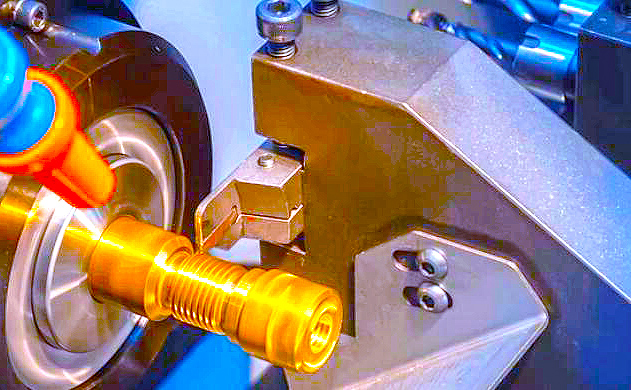

Employ a lathe to turn the shaft, ensuring its outer diameter and length conform to the design requirements.

As per the design specifications, utilize a milling machine to create grooves, keyways, threads, and other required features on the shaft.

Surface Treatment

Perform surface treatments including grinding, polishing, or coating to improve surface finish and corrosion resistance.

Surface Finishing Options for Custom Machined Shafts

In custom-machined shaft processes, various surface finishing options exist to optimize the quality and performance of shafts. Here are some prevalent choices:

Polishing

Enhances shaft smoothness, reduces friction resistance, and boosts wear resistance.

Surface Coating

Utilizing coatings like chromium or nickel plating can enhance shaft corrosion resistance and hardness.

Sandblasting

Improves surface quality, increases roughness, and can remove oxide layers.

Grinding:

Enhances dimensional accuracy and surface roughness, meeting high precision requirements effectively.

Anodizing: Ideal for aluminum alloy shafts, forming an oxide film to enhance wear and corrosion resistance.

Types of Machined Shafts and Their Applications

Various machined shaft types cater to diverse functions and structural designs, each serving specific purposes. Here are common types and primary uses:

Straight Shaft

Connects or transmits power in rotating equipment, capable of withstanding radial and axial loads.

Propulsion Shaft

Connects transmission devices for torque and rotational motion transmission, widely used in mechanical and automobile transmission systems.

Hollow Shaft

Features a hollow structure suitable for transmitting liquids, gases, or cables when space is a requirement.

Eccentric Shaft

Utilized to adjust the relative position between mechanical components with an asymmetrical central axis.

Spline Shaft

Contains specialized spline grooves to fix transmission parts and prevent relative sliding.

Considerations and Techniques in Manufacturing Shaft Components

Positioning Considerations

Attention to positioning reference selection, optimized clamping methods, and material heat treatment is essential to ensure enhanced stability and minimized errors.

Material Selection:

Material Selection

Choosing appropriate materials such as 45 steel, 40Cr, GCr15, and 65Mn, and adopting suitable heat treatment processes, fosters enhanced hardness and fatigue resistance.

Precision Requirements

Utilizing two-end center hole support for processing and employing specialized frames and chucks ensures the concentricity of various size steps and facilitates efficient subsequent processing.

How to Choose an Appropriate Custom Shaft Manufacturer?

To identify an appropriate custom shaft manufacturer, initiate by conducting thorough market research to compile comprehensive data on manufacturers and customer reviews. Subsequently, solicit recommendations from colleagues and associates within your industry. Engage in direct dialogue with manufacturers at pertinent trade shows to assess their technical competencies. Issue requests for quotations to several manufacturers, comparing their pricing structures and lead times meticulously. Concurrently, verify that the manufacturer possesses state-of-the-art technological apparatus and a proficient workforce. Delve into the intricacies of their service offerings, with a particular focus on technical support and post-purchase services. Once the optimal candidate is selected, formalize the partnership through a contract, ensuring all critical parameters such as technical requirements, quality benchmarks, and project timelines are explicitly delineated therein. Adhering to this methodical approach will enable you to pinpoint a manufacturer capable of delivering both premium products and exemplary service.

Conclusion

The comprehensive exploration of custom shaft manufacturing and associated aspects in this guide offers invaluable insights into the concept, significance, development prospects, advantages, materials, machining techniques, surface finishing options, types, considerations, and manufacturer selection process. This holistic view equips readers with the knowledge and understanding necessary to make informed decisions in the realm of custom-machined shafts.

FAQs

Choosing Runsom Precision for Your Custom Shaft or Machined Shaft

Opting for Runsom Precision for the processing of custom shafts or machined shafts offers access to a diverse set of professional services and technical support. With extensive expertise in five-axis CNC machining, Runsom excels in machining complex components. Additionally, our team of manufacturing engineers and machinists boasts over a decade of experience in CNC machining service, guaranteeing the production of top-notch custom parts and products. For specific requirements or to delve deeper into what Runsom has to offer, please don’t hesitate to contact us for a complimentary quote.