Un torno automático es lo que se conoce como una máquina de tornillo suizo. Es capaz de producir componentes torneados de precisión de gran volumen de manera precisa y eficiente. En este post hablaremos de las múltiples ventajas que ofrece en comparación con sus tornos correspondientes. Además de eso, repasaremos sus muchas aplicaciones.

¿Cuáles son los principales tipos de máquinas de tornillo suizo?

Las máquinas de tornillo suizo automáticas y controladas numéricamente por computadora (CNC) son los dos tipos más comunes que se analizan a continuación:

Máquina automática de tornillo suizo

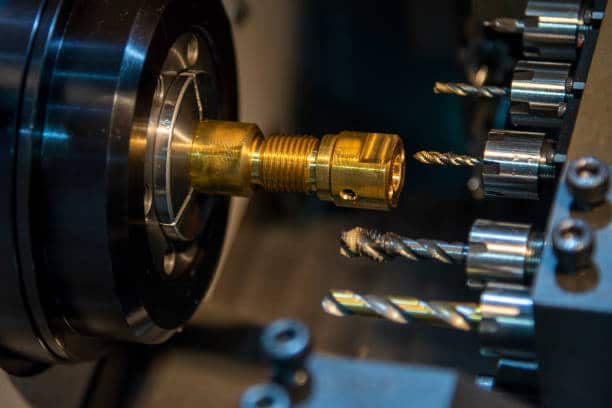

Los portaherramientas de una máquina de tornillo automática suiza están dispuestos radialmente alrededor del husillo, y el contrapunto de la máquina es coaxial con el husillo. Es ideal para la producción en masa de piezas diminutas de alta precisión rápidamente. Para tener en cuenta las variaciones en el paralelismo de la pieza de trabajo, las levas de disco reposicionan el cabezal y mueven las herramientas radialmente. Los apretados collares del husillo de la máquina automática Swiss Screw eliminan la desviación de los desechos, lo que permite que la máquina se deslice sobre cualquier impedimento.

Máquina de tornillo suizo CNC

Las máquinas de tornillo suizo CNC (control numérico por computadora), que son un tipo de máquina de tornillo suizo, mejoran la eficiencia y la precisión de la producción. Los procesos pueden llevarse a cabo simultáneamente y en rápida sucesión utilizando varias piezas de herramientas. En este procedimiento, la pieza de trabajo gira al mismo tiempo que el torno.

En términos de aplicación, la máquina de tornillo CNC es muy adaptable. A diferencia de las máquinas de tornillo de "husillo único" más comunes, esta puede acomodar una variedad más amplia de accesorios de herramientas, además de tener un husillo doble.

Las máquinas automáticas de tornillo suizo y las máquinas de tornillo suizo de control numérico por computadora (CNC) son excelentes opciones para proyectos largos debido a sus bajos costos y adaptabilidad. Una vez equipadas y programadas correctamente, muchas máquinas pueden funcionar con un solo operador, lo que las hace muy rentables para proyectos a largo plazo.

Dado que el collarín, el sustrato y el utillaje encajan perfectamente entre sí, las operaciones de mecanizado se pueden realizar con mayor precisión.

¿Qué características hacen que la máquina de tornillo suizo sea especial?

Como su nombre lo indica, la máquina de tornillo suizo fue desarrollada por relojeros en Suiza que buscaban una herramienta de corte más precisa. El principio de funcionamiento de este tipo de máquina es que la pieza a fabricar se monta en una corredera giratoria, y luego la corredera gira, lo que permite que la máquina de tornillo corte la pieza según las especificaciones requeridas.

A continuación se concluyen algunas características especiales que alberga:

- Hay un micrómetro en el portaherramientas para el ajuste.

- Estructura voluminosa, recorridos cortos de herramienta y alta rigidez

- Salida en alta precisión

- Tiempos de ciclo extremadamente cortos

- En lugar de mover la herramienta, la pieza de trabajo se puede mover axialmente en relación con la herramienta, formando características a lo largo de su longitud.

¿Cuáles son sus ventajas sobre otras máquinas de torno?

La capacidad de Swiss Screw Machine para operar con precisión milimétrica es solo una de sus numerosas ventajas. Swiss Screw Machine satisface una necesidad ya que las diferentes máquinas controladas numéricamente por computadora a menudo no pueden manejar componentes de tamaño micro. Todas las demás máquinas CNC no pueden igualar la precisión de corte de esta máquina (una tolerancia de 0,0002 pulgadas a una velocidad de 10 000 revoluciones por minuto).

Además de cortes precisos, también proporciona ventajas adicionales, incluidas las siguientes:

- Debido a la disposición compacta de las herramientas, es posible pasar de una herramienta a la siguiente en un segundo o incluso menos.

- La cantidad de tiempo dedicado a las operaciones puede reducirse a la mitad gracias a la colaboración simultánea de hasta cinco herramientas.

- Es posible que una máquina de tornillo suizo contenga hasta 20 herramientas, lo que contribuye a la versatilidad de la máquina y la convierte en una opción popular.

- Debido a que ofrece un acabado de superficie impecable, no es necesario realizar más pasos de acabado.

- Fresado, taladrado y aserrado son algunos de los procesos secundarios que se pueden realizar.

- El tiempo requerido para la configuración se reduce significativamente.

- Métodos de preservación de la calidad que son eficientes y no pierden tiempo.

¿Cuáles son los productos fabricados con máquinas de tornillo suizo?

Las máquinas de tornillos suizos crean más que tornillos a pesar de lo que implica su nombre. Viene en una amplia gama de piezas y productos a través de una variedad de métodos de mecanizado CNC y mecánicos rentables. Los productos fabricados por máquinas de tornillo suizas incluyen:

- Estrías

- husillos

- Guarniciones

- Chaveteros

- Medidores de neumáticos

- Pomos de metal

- varillas roscadas

- Sujetadores especiales

- Instrumentos médicos en miniatura

- Bioimplantes personalizados y estándar

¿Cuáles son sus usos y aplicaciones?

Hoy en día, Mecanizado CNC de tornillos suizos se considera comúnmente como un método eficaz para fabricar piezas y componentes de precisión que se utilizan en diversas industrias, entre ellas:

- Médico

- Aeroespacial

- Militar

- Automotor

- Electrónica

- Agricultura

- Hidráulica

- Construcción

- Equipos de energía

- Instrumentos musicales

La industria del automóvil depende en gran medida de las máquinas de tornillo suizo, pero también tienen muchos otros usos. Cuando los fabricantes de automóviles producen miles de automóviles por día, la capacidad de crear una gran cantidad de componentes a precios bajos es crucial, y la Swiss Screw Machine es la razón.

Las máquinas de tornillo suizo se utilizan en el sector de la electrónica debido a su precisión. Las capacidades de corte de alta velocidad de Swiss Screw Machine son especialmente útiles en la industria electrónica, que a menudo emplea una amplia gama de metales y materiales. Esto es así independientemente de la densidad del material que se esté cortando.

Aunque Swiss Screw Machine primero encontró su hogar en el sector de la relojería, posteriormente encontró aplicaciones en muchos otros. Una máquina de tornillo suizo es un equipo muy buscado debido a su capacidad para cortar patrones extremadamente detallados en una amplia variedad de materiales. Cuando esta potencia de corte se combina con el control de movimiento asistido por computadora, los usos potenciales se vuelven casi ilimitados. Esta es la razón por la cual industrias como la automotriz dependen de Swiss Screw Machines para producir sus componentes.

Trabaje con Runsom - ¡Ejecute su trabajo 24/7!

Somos el fabricante más confiable en el negocio cuando se trata de producir Piezas de tornillo suizo, así que acérquese a nosotros si está buscando uno. Gracias a la tecnología que sustenta nuestra plataforma, podemos mantener un funcionamiento ininterrumpido las 24 horas del día, los siete días de la semana. Incluso después de que nuestros trabajadores se hayan ido, nuestras sofisticadas máquinas de tornillo suizo seguirán funcionando, fabricando los componentes que desee en el plazo previsto y sin exceder el presupuesto asignado. Obtenga una cotización instantánea para empezar tu proyecto hoy!

Aprenda más sobre nuestro Mecanizado CNC suizo capacidad.

Otros artículos que te pueden interesar: