CNC Machining in Polycarbonate/PC

Polycarbonate, or PC, is well-known for its mechanical properties, enabling it to be used in CNC machining Polycarbonate parts or components for broad usage across different industries.

What Is Polycarbonate/PC Plastic?

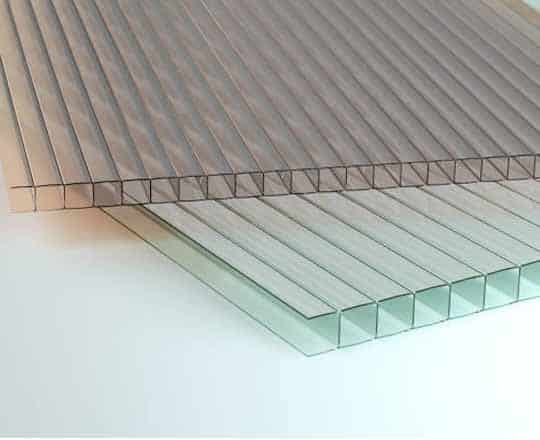

Polycarbonate (also known by the abbreviation PC) is an amorphous thermoplastic that tends to soften first before melting, without a set melting point. Its excellent lightweight, clarity, and shatter resistance make it a great substitute for glass. And PC has higher heat tolerance than Acrylic. Polycarbonate is a perfect plastic material in CNC machining because it can be easily machined with its exceptional mechanical properties, including good impact strength, hardness, toughness, and high-temperature tolerance. CNC machined PC products can be found in broad areas such as semiconductor, mechanical, transportation, electronics, optical, automotive, medical, and more industries.

Runsom utilizes CNC machining techniques including multi-milling, turning, drilling, and so on to process Polycarbonate in black or clear sheet and bar stock. Our facilities and equipment are sophisticated enough to minimize the operation errors and vibration during machining processes, which greatly enables us to manufacture PC components with consistent quality and accuracy.

Polycarbonate CNC Machining Specification

Application

Transparent parts, light pipes, wheels, gaskets, and car headlight lenses.

Tolerances

It is determined by the desired effect and the PC type used. A tolerance of ±0.010” (±0.25 mm) is available at Runsom.

Advantages

UV resistance, excellent fracture toughness, heat resistant, electrical insulation, good machinability, and great impact strength.

Wall Thickness

It is mostly decided by the available machine and part geometry. A minimum wall thickness of ±0.03” (±0.8 mm) is available at Runsom.

Lead Time

As fast as 3 days, but it will be finally determined by part complexity and order quantity.

Max Part Size

200 x 80 x 100 cm(the available size is mostly decided by the machine and part geometry).

Processes

3-axis & 5-axis CNC milling.

Finishes

Vapor polishing, Scratch-resistant coating.

Polycarbonate CNC Machining Manufacturer – Custom CNC Machined PC Plastic Parts

If you are seeking a reliable supplier to manufacture your Polycarbonate products or to outsource your CNC machining demands, Runsom Precision may have the right answers for your crucial needs. Runsom Precision has many years of experience in CNC machining of plastics, metals, and a variety of materials, and no project is too complex for us. Working with a wealth of materials, we have created numerous polycarbonate CNC machined parts, polycarbonate milled parts, polycarbonate turned parts, and more through our advanced and efficient CNC machining technologies including CNC milling Polycarbonate, CNC turning Polycarbonate, CNC drilling Polycarbonate, etc.

Our goal is always to provide each customer with the best quality products at the most cost-effective price. Thus, we consistently emphasize the significance of customers’ satisfaction for our development and improvement. Whether for product designs, prototypes, small-scale models, or large-batch products, we keep focusing on every detail in every stage and conduct strict quality control measures to ensure customers receive their parts as per each specification.

Polycarbonate CNC Machined Parts Applications

As a relatively popular plastic material in CNC machining, Polycarbonate is ideal for manufacturing structural components as its incredible impact resistance. With almost twice the impact strength of ABS, PC plastic can be formed and machined easily without breaking or cracking. Runsom has delivered a wide variety of components made from Polycarbonate for broad industries, part of PC products we fabricated including:

Our Strengths in CNC Polycarbonate Machining Services

Polycarbonate FAQs

Polycarbonate is highly machinable. It is a thermoplastic material that has high impact strength and toughness, excellent creep, and optical clarity. It comes in FDA-compliant grades, as well as in compounds that offer greater weight-bearing and wear resistance.

Polycarbonate works well on end mills of all sizes; however, the tool should be very sharp, preferably one designed for use with plastics. If the heat accumulation is too high in some cases, the polycarbonate will melt under the end mill.

CNC machining of polycarbonate is quite popular. The great impact resistance of this material makes it suitable for structural components. The impact strength of polycarbonate is almost twice that of ABS, making it one of the highest impact strength materials of all common engineering plastics.

Polycarbonate is a stronger material, 250 times more impact resistant than standard glass. Polycarbonate offers more resilience than Acrylic, making it ideal for demanding applications such as bulletproof windows. But the proper selection of certain materials is determined by the function and usage of a certain application.

Polycarbonate is one of the popular plastics applied in manufacturing. It has a lightweight and high strength, which makes it perfect for forming parts or accessories for mobile phones, eyeglass lenses, CDs, DVDs, shatterproof windows, etc. Its most notable usage case is making first-generation MacBook laptops, optical disks, and safety goggles.