CNC Machine Shop In China - Top China CNC Machining Service

Incredibly High Precision & Tolerance? Think about Runsom.

Custom Micro Machining Service in China. Think about Runsom if other CNC machine shops have no capability to complete your high-standard components. We have a team with rich experience in producing parts with tight tolerance close to 1 to 100-micron accuracy. We specialize in rapid prototyping and manufacturing services and are dedicated to professionalism and trustworthiness. We guarantee precision, quality, and affordability for any quantity of machined parts you need.

Our advanced CNC technology and team of experienced engineering experts enable us to deliver diverse CNC machining solutions including CNC milling services, CNC turning, EDM, and surface treatment finish. Don't hesitate to get in touch with us today to discuss your project requirements! You’ll get an instant quote for free within 24h.

A machine shop refers to a place in which subtractive manufacturing takes place, where manual or automated CNC machines are used to manufacture products.

The word “shop” is not just simply as its literal meaning of “store”, but rather a floor, a building, or even a room in the initial stage of a small business, in which engineers and other technical staff members can operate machinery to bring an idea into production. This place makes it possible to produce different machined components including metal, plastic, and other types of parts.

The word “machine" refers to a piece of equipment with cutting tools to remove a plastic or metal block, or other raw materials, involving some processes such as turning, milling, drilling, etc. The facilities in a CNC machine shop may be variable from specific industrial needs and machining purposes, but the main concern is subtractive manufacturing equipment.

Up to now, machine shops have been well-developed at the cutting edge of manufacturing technology. It will greatly help many businesses stay in a dominant position in the market without high costly investments in hardware facilities or personnel training. Therefore, there is an increasing demand for the service of a machine shop, no matter of a small or large business.

Rather than only manufacturing products of a certain brand, as a third-party manufacturer, Runsom can provide customers around the world across various industries with online custom CNC machining services.

Automated vs Manual Machines

Nowadays, CNC machining is indispensable, especially widely used for the bulk of its operations. Given the excellent advantages of the new technology, CNC machining shops could carry out all the operations that a manual machine could do, and even more, are replacing traditional machine shops.

The following shows several benefits that CNC machining confers to a manufacturing facility.

When it comes to mass production or prototyping, a CNC machine shop could be a primary choice for reducing a product’s time-to-market and ensuring market share. Moreover, digital models like CAD, and CAM software, are feasible in CNC machining operations. A 3D model takes less time than manually writing code and can be reused with a different manufacturing partner.

Dimensionally accurate parts can be manufactured in a CNC machine shop. Tight tolerance of CNC machined parts is realized and the value of the finished object is increased in high-volume or consistent manufacturing of the same object.

The process of CNC machining is carried out behind a guard even a closed transparent door, which minimizes the human element in the practical machining phase decreasing errors as well avoiding accidents. Its additional safety features are as follows:

- Emergency stop button: To stop if there is any malfunction. It can be found in several locations for quick and safe access.

- Guard fence: This fence covers the largest working area of the machine and stops the operator from carelessly getting too close to a running machine.

- Noise-proof enclosure: This enclosure makes the operator free from noise and acts as a shield between the operator and the running device.

- Curtain guards: This protects the operator from shavings and tool debris.

- Contact mats: To prevent exposure to the moving arm in case of that an operator steps onto these mats.

A CNC machining center can be mounted with several tools at the same time. Moreover, some latest CNC machines are equipped with automatic tool changers. There is no need for human involvement during manufacturing upon loading tools into the tool holder. The desired finished model will be delivered by the CNC machine.

The production process of CNC machining can be operated overnight and with no need for breaks. Besides, it won’t cause undue wastage, making it possible to increase manufacturing volume and lowing production costs simultaneously. Also, the labor cost will be reduced as the process can be operated and observed by a single operator.

Manual machining remains its stage in the manufacturing markets regardless of the abundant advantages of CNC machine shops. It has its distinct benefits as well:

Tips to Choose A Right CNC Machine Shop

If you are looking for a CNC machine shop for product development or business prosperty, there are some factors that you are supposed to consider.

You'd better give a call to the machine shop or even pay a visit to its facility at your convenience before working with it. It will let you clearly know whether the machine shop you're ready to cooperate with has advanced CNC machines, measuring equipment, experienced machinists, and quality inspectors.

The first thing you think of may be the price before you place an order with a CNC machine shop. Each one is delighted to cooperate with a machine shop that offers the lowest rates. However, you should keep in mind that a good price should never be at the expense of quality. Therefore, selecting a reliable machine shop may help to avoid lots of potential troubles.

Many machine shops may assure you that they can deliver your order within a specified time and budget, but it turns out to be a failure. You may get into trouble because the machine shop cannot deal with your projects timely. It might be more prudent to have a profound understanding of the capabilities and flexibility of the machine shop.

Before starting the production, one significant matter you should never ignore is to sign a Non-Disclosure Agreement (NDA) with the machine shop to make sure your design will not be revealed to any third parties.

Still hesitate about the above issues and uncertain factors you may encounter when choosing a CNC machine shop? Runsom can provide perfect solutions to your project with a firm promise of all of the above. You may rest assured that your CNC machined parts or prototypes will be shipped anywhere in the world within the promised time.

How Runsom Performs Better Than Traditional CNC Machine Shops

Runsom continues to forge ahead to serve a wide range of industries saving time and money on their projects. Our superior CNC machine shops make the impossibility possible, no matter what complex geometry and tight tolerance your components require and wherever you are. Runsom is able to machine your parts in ultra-precision CNC machining - we promise you correct specifications, and specified time and budget. Our CNC specialists are highly skilled in machining technologies including:

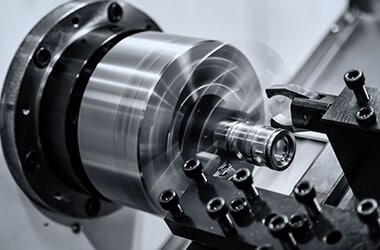

Precision CNC turned parts at the most competitive pricing, with fast lead times, and without requirements for minimum order quantity. The instant manufacturability feedback offered by Runsom’s professional technological team allows us to optimize your part designs for the CNC turning process and fulfill all requirements you need. Learn more...

Runsom has competitive markets in complex part manufacturing with ultra-precision 5-axis CNC machining with decades of incomparable innovation and experience. We are experts in true 5-axis machining, which enables us to quickly produce "almost impossible to make" 5-axis parts. Learn more...

Swiss CNC machining is a specialized process to machine small, high-precision turned parts. Precision Swiss CNC machining services are our specialty at Runsom. We can offer you suitable cost-effective solutions in Swiss-type machining and produce high-quality precision-turned parts. Learn more...

ISO 9001:2015 CNC Machine Shop Bulids High Precision Machining

As an ISO 9001:2015 certified CNC machine shop, Runsom has confidence in manufacturing every part with industry quality standards. Each of our staff is dedicated to exceeding these standards rather than just meeting the criteria. Our facilities also meet some special requirements, such as temperature control needs. Runsom is happy to accept any challenge in different industries. We strive for creating the best CNC machining services in the industry, including CNC milling, CNC turning/lathe, Swiss CNC machining, and 5-axis CNC machining.

CNC Machining FAQs

The main costs associated with CNC machining can be grouped into machining time, start-up costs, material costs, and feature costs. To reduce costs you need to understand the impact of these factors on cost.

- The best way to reduce machining time is to design features that can be machined quickly, for instance, choosing the correct radii for internal corners, reducing cavity depth, increasing wall thicknesses, limiting thread length, and designing holes with standard sizes.

- Material costs can be reduced by considering the size of the blank required, and the cost and machinability of the bulk material (softer alloys are faster to machine).

- Start-up costs can be reduced by reducing the number of part rotations or repositioning required to finish the part, for example, separating geometries into multiple parts that can be assembled later.

- Feature costs can be reduced by only using tolerances when strictly necessary, removing all text & lettering, and avoiding multiple surface finishes.

For more details, please check out our guide about minimizing the cost of CNC machined parts.

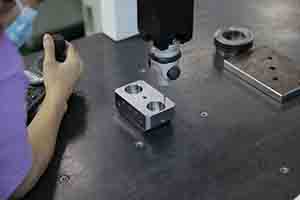

Our sound quality-control system makes sense that thousands of customers place their CNC machining orders in our company. The regular check and testing starts from incoming materials to shipment, ensuring each part is produced accurately for your specifications.

We possess a comprehensive, standardized inspection report with every order to ensure quality metrics are being met, and offer a first article inspection service on orders of 100+ units. We also have multiple certifications available on request, including but not limited to ISO9001, ISO13485, and AS9100.

Follow this page - Runsom Quality Control Standard to know more about our quality assurance measures.

Due to the spinning motion produced by the CNC milling machine's cutter, the surface finish of CNC machined parts will have visible tool marks. If you require a smooth, unblemished finish for your parts, we recommend choosing a secondary finish: grained finish (can only be applied to the outside of machined enclosures due to geometry) or powder coat.

To know more information about surface finishes for CNC machining, you can refer to this article.

CNC machining is widely used across a wide range of industries. It is common in aerospace, automotive, consumer electronics, robotics, agriculture, and other fields that frequently use metal parts. It is also widely used in medical devices, household goods, energy, oil and gas, and other consumer applications. It is one of the most common processing methods in the manufacturing field.

Runsom has offered ultra-precision CNC crafted components for global industries including oil and gas CNC machining, medical instruments CNC machining, optical CNC machining, tool and die parts CNC machining, motorcycle components CNC machining, electronic enclosures CNC machining, automotive parts CNC machining, etc.

Runsom was established by mechanical engineers and now we have a talented and powerful team. Until now, we've written a lot of content on CNC machining over the years. You can find a selection of resources below, or you can head to our knowledge hub and filter on CNC machining case studies, in-depth design guidelines, and explanations of different surface finishes.

We've also written a complete CNC machining design guide, which has been updated for 2020. Here you can learn about how many different kinds of mills and lathes work and how to select the best suitable materials for CNC machining, so you can easily figure out their benefits & limitations. You'll also learn the basic design rules for machining, the most common applications of each material, and surface finishes available for CNC machining, so you can make the right choice every time.

A drill press is viewed as the basic manufacturing machine tool. It is used to drill holes into any kind of part. The movement of a drill press is controlled by a lever. Besides drilling holes, it can also be applied to various manufacturing work, given its more accuracy and stability than handheld drills.

A drill press is viewed as the basic manufacturing machine tool. It is used to drill holes into any kind of part. The movement of a drill press is controlled by a lever. Besides drilling holes, it can also be applied to various manufacturing work, given its more accuracy and stability than handheld drills. A milling machine removes a block of raw materials from the workpiece with rotary cutters. Extensive machining operations can be carried out since there exist many series and sizes of milling cutters for conducting various kinds of cut, from threading to roughing. It's feasible to machine an irregular surface with a milling machine, but a flat surface would be preferable. It is usually used in some operations like boring, gear cutting, slotting, and drilling.

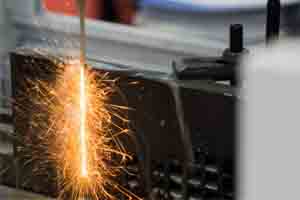

A milling machine removes a block of raw materials from the workpiece with rotary cutters. Extensive machining operations can be carried out since there exist many series and sizes of milling cutters for conducting various kinds of cut, from threading to roughing. It's feasible to machine an irregular surface with a milling machine, but a flat surface would be preferable. It is usually used in some operations like boring, gear cutting, slotting, and drilling. EDM (Electrical Discharge Machining) is referred to as a process where particles from the surface of the part are vaporized by electric currents. This method ensures the part not to be deformed when processing, allowing the cutting force to be close to zero. This process is greatly ideal for dies cavities and hardened aerospace parts.

EDM (Electrical Discharge Machining) is referred to as a process where particles from the surface of the part are vaporized by electric currents. This method ensures the part not to be deformed when processing, allowing the cutting force to be close to zero. This process is greatly ideal for dies cavities and hardened aerospace parts. A CNC machining center is an improved version of the CNC milling machine, allowing it to conduct high-grade subtractive manufacturing with a Computer Numerical Control (CNC) system. It makes it possible to produce almost any shapes you want with a 3, 4, or 5-axis CNC machining center. The number of axes significantly determines the complexity of the part geometry it can make and has an impact on production cost. It is ideal for precision and complex parts due to its unmatched capability, easy setup, and high surface finish.

A CNC machining center is an improved version of the CNC milling machine, allowing it to conduct high-grade subtractive manufacturing with a Computer Numerical Control (CNC) system. It makes it possible to produce almost any shapes you want with a 3, 4, or 5-axis CNC machining center. The number of axes significantly determines the complexity of the part geometry it can make and has an impact on production cost. It is ideal for precision and complex parts due to its unmatched capability, easy setup, and high surface finish. A grinding machine employs a high-quality grinding abrasive wheel to grind the workpiece, forming a highly precise dimension with neat surface finishes. Such an operation can make the rough surface smoother by removing irregularities. And it is only used for parts that require extremely tighter tolerances because it’s costly and time-consuming.

A grinding machine employs a high-quality grinding abrasive wheel to grind the workpiece, forming a highly precise dimension with neat surface finishes. Such an operation can make the rough surface smoother by removing irregularities. And it is only used for parts that require extremely tighter tolerances because it’s costly and time-consuming. There may require a surface finish to get additional properties for machined parts, like glossiness, smoothness, colors, or mirror-like surface finishes. These special treatments can be achieved by various pieces of equipment in a CNC machine shop that offers anodizing, polishing, and sandblasting services.

There may require a surface finish to get additional properties for machined parts, like glossiness, smoothness, colors, or mirror-like surface finishes. These special treatments can be achieved by various pieces of equipment in a CNC machine shop that offers anodizing, polishing, and sandblasting services. A coordinate measuring machine (CMM) is a piece of control equipment used to measure the geometry of the part and evaluate its properties, ensuring the exact tolerances of the part and error-free operation of various orders. Besides, it can offer data reports on machined parts. The accuracy and quality of the part are guaranteed with a CMM.

A coordinate measuring machine (CMM) is a piece of control equipment used to measure the geometry of the part and evaluate its properties, ensuring the exact tolerances of the part and error-free operation of various orders. Besides, it can offer data reports on machined parts. The accuracy and quality of the part are guaranteed with a CMM. Machines in a CNC shop perform different manufacturing tasks, either manual machining operated by a machinist or equipped with CNC (Computer Numerical Control) technology.

Machines in a CNC shop perform different manufacturing tasks, either manual machining operated by a machinist or equipped with CNC (Computer Numerical Control) technology.