Overmolding is a manufacturing process that involves the injection molding of one material over another. Since the materials engaged in overmolding must bond together, the plastics must be compatible with each other. Material compatibility stems from chemical compatibility, which is a measure of how stable a material is when in contact with another material. If two materials come into contact with each other and incure a chemical reaction, they are incompatible and not suitable for multi-material injection molding. For chemically incompatible materials, positive fastening features or mechanical bonding are usually recommended. This links the two materials together without a chemical bond.

Here, we will exhibit the overview of the overmolding process and illustrate its difference from other similar molding methods in a table. An overmold material compatibility chart is provided to help you check whether two of your prospective materials can be chemically or mechanically compatible.

What Is Overmolding?

Overmolding is a manufacturing process that involves the injection molding of one material over another. The process involves the use of a mold that is designed to produce two or more distinct parts, with one part being molded over the other. The result is a single, integrated component with multiple materials and functionalities.

Overmolding is often used to combine two or more materials that have different properties, such as different colors, textures, or hardness. It is also used to add functionality to a component, such as adding a grip or a soft touch surface.

There are several types of overmolding, including insert overmolding, two-shot overmolding, and co-injection overmolding. Insert overmolding involves the injection of one material over an insert, which is a pre-molded component made of a different material. Two-shot overmolding involves the injection of two different materials in a single molding cycle, while co-injection overmolding involves the injection of two different materials at the same time.

Overmolding is a versatile manufacturing process that is used in a wide range of industries, including automotive, medical, and consumer products. It allows for the production of complex and functional components with a single molding process, reducing the need for assembly and increasing efficiency.

Injection Overmolding Process

The injection overmolding process is a manufacturing process that involves the injection molding of one material over another. It is a versatile process that is used to combine two or more materials, add functionality to a component, or create a single, integrated component with multiple materials and functionalities.

The injection overmolding process typically involves the following steps:

- Design and tooling: The first step in the injection overmolding process is the design and development of the mold and tooling. This involves creating a detailed design of the component and selecting the appropriate materials and process parameters. The mold and tooling are then fabricated to produce the desired component.

- Setup: Once the mold and tooling are complete, the injection molding machine is set up for the overmolding process. This involves installing the mold in the machine, setting the process parameters, and ensuring that all of the necessary materials and equipment are in place.

- Pre-molding: In some cases, a pre-molding process may be required before the overmolding process begins. This could involve the injection molding of a separate component or the insertion of a pre-molded component into the mold.

- Injection: The overmolding process begins with the injection of the first material into the mold. The material is heated and pressurized as it is injected into the mold, filling the cavities and taking on the shape of the component.

- Overmolding: Once the first material has been injected and has cooled to a certain point, the second material is injected over the first material. The second material is typically injected at a lower temperature and pressure to avoid damaging the first material.

- Cooling and ejection: After the overmolding process is complete, the mold is allowed to cool and the component is ejected from the mold. The component is then inspected and finished as needed.

The injection overmolding process is a highly efficient and cost-effective way to produce complex and functional components with multiple materials.

Overmolding Materials

The materials used in the overmolding process depend on the specific requirements of the component being produced.

Some common materials used in overmolding include:

Thermoplastics

Thermoplastics are polymers that can be melted and reshaped multiple times. They are commonly used in overmolding applications due to their versatility and ease of processing. Some common thermoplastics used in overmolding include:

- Polyethylene

- Polypropylene

- Polystyrene

- Polycarbonate

Elastomers

Elastomers are polymers that have the ability to stretch and return to their original shape. They are commonly used in overmolding applications to add flexibility and grip to a component. Some common elastomers used in overmolding include:

- Silicone

- TPE (thermoplastic elastomer)

- TPU (thermoplastic polyurethane)

Metals

Metals can also be used in overmolding applications, typically as an insert or pre-molded component. Common metals used in overmolding include aluminum, brass, and stainless steel.

Composites

Composites are materials that are made from a combination of two or more materials with different physical or chemical properties. They are commonly used in overmolding applications to combine the properties of different materials. Some common composites used in overmolding include:

- Glass-fiber reinforced plastic (GFRP)

- Carbon-fiber reinforced plastic (CFRP)

The choice of materials for overmolding depends on the specific requirements of the component being produced, such as the desired strength, flexibility, or appearance. The compatibility of the materials and the processing conditions of the overmolding process must also be considered.

Overmold Material Compatibility

Chemical Bonding

This bonding process refers to two chemically compatible materials being shaped into a strong bond with each other. It’s worth noting that not all materials work well with each other.

Mechanical Interlocking

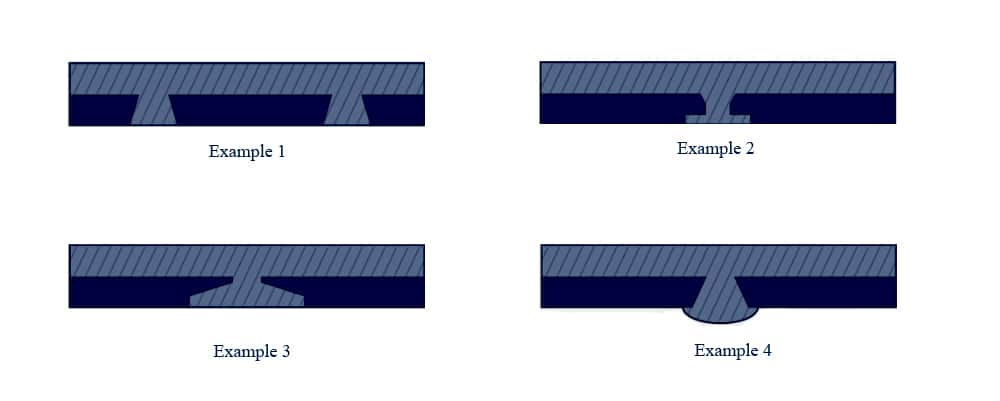

What if your material is incompatible, cannot achieve the desired bond strength, or you want to make sure your material will not flake off due to repeated use? At this point, it makes sense to devise a mechanical interlock that physically secures the cladding material to the substrate. There are many manners to design these into parts (see the picture below).

Overmolding Material Compatibility Chart

| Substrate Material | ||||||

|---|---|---|---|---|---|---|

| Overmold Material | ABS Lustran | ABS/PC Cycolo C2950-111 | PC Lexan 940-701 | PBT Valox 357-1001 | PP Profax 6323 | Nylon 66 ZYTEL 103 HSL NC010 |

| TPU - Texin983-000000 | C | C | C | C | M | M |

| TPV - Santoprene101-87 | M | M | M | M | C | M |

| TPE - Santoprene101-64 | M | M | M | M | C | M |

| LSR - Elastosil3003/30 A/B | - | - | M | M | - | M |

| TPC - Hytrel 3078 | C | C | C | C | M | M |

| TPE-Versaflex OM1060X-1 | C | C | C | M | M | M |

| TPE-Versaflex OM6240-1/td> | M | M | M | M | M | C |

| TPE-Versaflex OM6258-1 | M | M | M | M | M | C |

| TPE-Versaflex OM1040X-1 | C | C | C | M | M | M |

C = chemical bond

M = mechanical bond (recommended)

What Are the Benefits and Applications of the Overmolding Process?

Overmolding offers several benefits, including:

- Reduced assembly: Overmolding allows for the production of complex and functional components with a single molding process, reducing the need for assembly and increasing efficiency. This can lead to cost savings and improved product quality.

- Improved functionality: Overmolding allows for the combination of two or more materials with different properties, such as different colors, textures, or hardness. This can improve the functionality and performance of the component, as well as enhance its appearance.

- Enhanced durability: Overmolding can improve the durability of a component by adding a layer of protection or by combining materials with different properties, such as adding a hard outer layer to a soft inner layer.

- Customization: Overmolding allows for the customization of components by allowing for the use of different materials and colors. This can be useful in applications where aesthetics or branding are important.

- Versatility: Overmolding is a versatile process that can be used in a wide range of industries and applications, including automotive, medical, and consumer products. It is suitable for producing small and large components and can be used with a variety of materials.

Products created through overmolding can be found everywhere in our daily life. Here, we categorized them into five main applications in which overmolding is commonly used:

- Automotive: Overmolding is commonly used in the automotive industry to produce parts and components with multiple materials and functionalities. For example, overmolding is used to produce dashboard components, door handles, and steering wheel grips.

- Medical: Overmolding is used in the medical industry to produce components with enhanced durability, flexibility, and grip. It is commonly used to produce medical devices, such as syringes, catheters, and tubing.

- Consumer products: Overmolding is used in the production of consumer products to add functionality, durability, and aesthetics. It is commonly used to produce components for appliances, electronics, and sporting goods.

- Industrial: Overmolding is used in the industrial industry to produce components with improved performance and durability. It is commonly used to produce parts and components for equipment and machinery, such as gears, bearings, and seals.

- Aerospace: Overmolding is used in the aerospace industry to produce lightweight and functional components. It is commonly used to produce parts and components for aircraft and spacecraft, such as cockpit controls and instrument panels.

Overmolding Vs. Insert Molding

Insert molding is a part of overmolding. Here, you can say that all insert molding is overmolding, but not all overmolding is insert molding. To understand their distinctions, it would be better to illustrate them in a table.

| Insert Molding | Overmolding | |

| Injection Type | This process inserts metal into a mold. | This process infuses multiple materials to create a single part. |

| Example | Medical equipment, automobile ducts, vacuum hose connectors, heavy parts, filters. | Power tools and hand tools, toys, PCB, car steering wheels, phones, RFID. |

| Benefits | Assembly time is quicker than overmolding The process reduces the size and weight of the part It’s cost-effective | Stable finishing Long durability Secure More cost-effective than post-molding fabrication |

If you still feel perplexed with the material compatibility for overmolding, feel free to reach out to experts at Runsom Precision. We possess extensive experience in CNC machining and plastic injection molding for over ten years and can help you with solutions to the selection of the right material for your crucial project. Let’s build an incredible result together!