Standard nail sizes refer to the dimensions of nails, including their length and diameter. The size of a nail is typically expressed in inches or millimeters and is determined by the specific application and the materials being fastened.

In the United States, common nail sizes are expressed in penny sizes, with the length of the nail being represented by the number and the diameter being represented by the word “penny.” For example, a common 16d nail is 3.5″ long with a 11/32″ head diameter and a 8 gauge shank. Other common penny sizes include 6d, 8d, 10d, 12d, and 20d.

In addition to penny sizes, nails are also available in metric sizes, which are expressed in millimeters. Common metric nail sizes include 25mm, 32mm, 40mm, 50mm, and 63mm.

It is important to use the correct size of nail for a specific application, as using a nail that is too large or too small may result in a weaker hold or other problems. It is also important to consider the type of nail that is best suited for the material being fastened and the specific application.

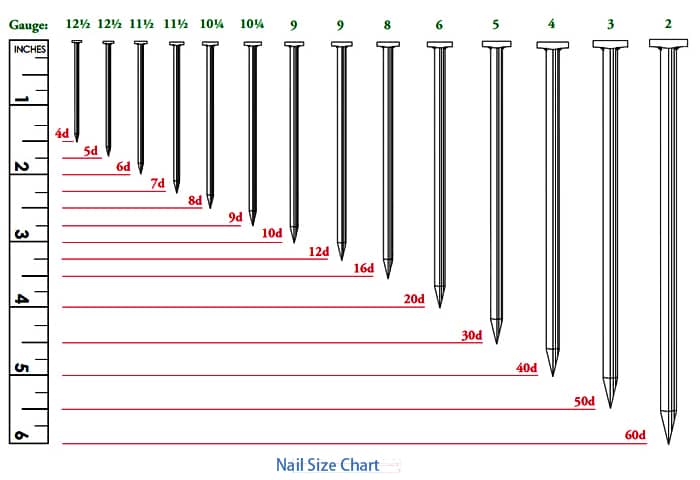

Standard Nail Size/Nail Measurement

The following nail size charts display industry standards for nails and their dimensions. Nail sizes are defined as a penny size, also known as a pennyweight. This is based on a system of nails sold by the penny. The term d is used to describe penny sizes, so a 16 penny nail is also known as a 16d nail, and an 8 penny nail is known as an 8d nail. Despite the penny system, pennyweight is not an exact measure of nail weight, gauge, or any other measurements. A common 10d nail has a 3″ length, a 5/16″ head diameter, and a 9 gauge shank.

Although the penny system is still frequently used, it is considered to be outdated, and some international vendors do not support it. The shank diameter and length refer to the shaft portion of the nail, which is driven into the surface. The head is the top of the nail that is hit with a hammer to drive it into the material.

Table 1 – Common Nail Sizes Chart

| Penny Size | Gauge | Shank Diameter (Nominal) | Shank Length (Nominal) | Head Diameter (Approx.) |

| 2D | 15 | 0.072 | 1” | 3/16″ |

| 2D | 14 | 0.083 | 1” | 13/64″ |

| 3D | 14 | 0.083 | 1.25″ | 13/64″ |

| 4D | 12 | 0.109 | 1.5″ | 1/4″ |

| 5D | 12 | 0.109 | 1.75″ | 1/4″ |

| 6D | 11 | 0.12 | 2” | 17/64″ |

| 8D | 10 | 0.134 | 2.5″ | 9/32″ |

| 10D | 9 | 0.148 | 3” | 5/16″ |

| 12D | 9 | 0.148 | 3.25″ | 5/16″ |

| 16D | 8 | 0.165 | 3.5″ | 11/32” |

| 20D | 6 | 0.203 | 4″ | 13/32″ |

| 30D | 5 | 0.22 | 4.5″ | 7/16” |

| 40D | 4 | 0.238 | 5” | 15/32″ |

| 60D | 4 | 0.238 | 6” | 17/32″ |

Table 2 – Annular & Threaded Nail Sizes Chart

| Penny Size | Shank Diameter (Nominal) | Shank Length (Nominal) |

| 6D | 0.12 | 2″ |

| 8D | 0.12 | 2.5″ |

| 10D | 0.135 | 3” |

| 12D | 0.135 | 3.25″ |

| 16D | 0.148 | 3.5″ |

| 20D | 0.177 | 4” |

| 30D | 0.177 | 4.5” |

| 40D | 0.177 | 5” |

| 50D | 0.177 | 5.5″ |

| 60D | 0.177 | 6” |

| 70D | 0.207 | 7” |

| 80D | 0.207 | 8” |

| 90D | 0.207 | 9” |

Table 3 – Box Nail Sizes Chart

| Penny Size | Gauge | Shank Diameter (Nominal) | Shank Length (Nominal) |

| 3D | 14-1/2 | 0.076 | 1.25″ |

| 4D | 14 | 0.080 | 1.5″ |

| 5D | 14 | 0.080 | 1.75″ |

| 6D | 12-1/2 | 0.098 | 2” |

| 7D | 12-1/2 | 0.098 | 2.25″ |

| 8D | 11-1/2 | 0.113 | 2.5″ |

| 10D | 10-1/2 | 0.128 | 3″ |

| 16D | 10 | 0.135 | 3.5″ |

| 20D | 9 | 0.148 | 4″ |

What Are Nails?

A nail is a thin, pointed rod made of metal or other materials that is used to fasten materials together. It is driven into wood or other materials using a hammer or nail gun, and the sharp point helps it to hold the materials together. Nails are commonly used in construction, carpentry, and other applications where a strong, secure hold is needed.

There are many different types of nails, including common nails, finishing nails, brads, and roofing nails. Each type of nail is designed for a specific purpose, such as holding together framing materials, finishing surfaces, or attaching roofing shingles. Nails are also available in a range of sizes, with the length and diameter of the nail being determined by the specific application.

Overall, nails are a simple and effective fastening solution that is widely used in a variety of applications. They are easy to install and provide a strong hold, but they may not be as versatile or adjustable as screws.

What Are the Differences between Nails and Screws?

Nails and screws are both fasteners that are used to hold materials together, but there are several key differences between them:

- Design: Nails are thin, pointed rods made of metal or other materials that are driven into wood or other materials using a hammer or nail gun. Screws are similar to nails, but they have threads that allow them to be screwed into materials, rather than being driven in with force.

- Hold strength: Screws generally have a stronger hold than nails, because the threads allow them to grip the material more securely. This makes them better suited for applications where a strong, secure hold is required, such as in construction or when attaching heavy objects.

- Versatility: Screws can be used in a wider range of materials than nails, because they can be tightened or loosened as needed. This makes them more versatile and allows them to be used in applications where the materials may need to be removed or adjusted.

- Appearance: Screws are typically more visible than nails, because the heads are usually larger and more prominent. This can be an advantage in some applications, such as when a decorative look is desired, but in other cases, it may be more desirable to have a more discreet fastener.

- Installation: Nails are typically driven into materials using a hammer or nail gun, while screws are typically installed using a screwdriver or drill. Screws may also require pre-drilling, depending on the material and size of the screw.

Overall, nails and screws are both useful fasteners, but they have different characteristics and are best suited for different applications. Screws are generally stronger and more versatile than nails, but they may be more visible and require more time and effort to install. Nails are simpler and faster to install, but they may not provide as strong a hold as screws.

Types of Nails

Nails come in a wide range of types and sizes. They are designed to provide strong resistance to both pulling and shearing forces, with the shank diameter determining the shear strength and the shank design affecting the pullout strength. Common types of nails are listed below:

- Common nails are the most common type of nails and are used for general purpose projects. They have a large, flat head, and they are made of steel or iron.

- Finish nails are thinner and shorter than common nails and usually have a smaller head. They are commonly used for trim work and furniture making.

- Brad nails are even thinner and shorter than finish nails and are used for very detailed trim work. They also have a smaller head.

- Roofing nails have a large, flat head and a longer shank than other nails. They are used for attaching roofing material to the roof.

- Concrete nails are thick, heavy-duty nails and are used for attaching materials to concrete. They have a large, flat head and a long shank.

- Masonry nails are thicker and longer than concrete nails and are used for attaching materials to brick and stone. They have a large, flat head and a long shank.